Nanometer scale inhibitor, and preparation method thereof

A kind of antiscalant and nanotechnology, which is applied in the field of new nanoscale antiscalant and its preparation, can solve the problems of environmental pollution and high cost of organic antiscalant, achieve good application prospects, improve operating efficiency and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] A preparation method of nano scale inhibitor, adding nano Al in cooling water 2 O 3 Granules to a concentration range of 0.0005g / L~1g / L, and then add a dispersant, the dispersant is sodium dodecylbenzene sulfonate (SDBS) or sodium dodecyl sulfate (SDS), The mass percentage concentration of the dispersant in the aqueous solution ranges from 0 to 2%, and then stirs for 1 to 3 hours and ultrasonically disperses for 20 to 3000 minutes to obtain nano Al with a particle size range of 10 to 800 nm. 2 O 3 Aqueous solution of particles.

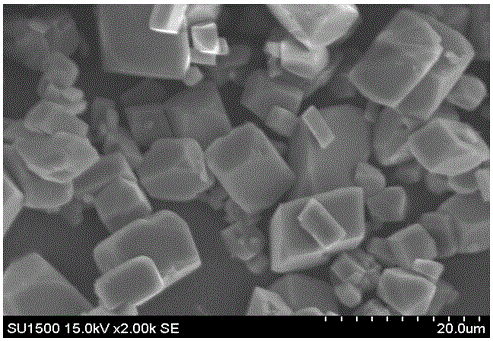

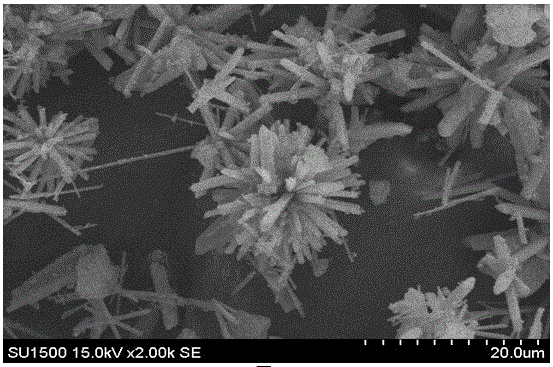

[0019] Add nano Al in the cooling water 2 O 3 Scale inhibitor, when the concentration of scale-forming ions in the cooling water is large and scaling phenomenon occurs, nano-Al 2 O 3 Particles can affect the formation process of scale-forming substances and cause lattice distortion of inorganic scales such as calcium carbonate (see attached figure 1 And figure 2 ), and reduce the adhesion work between the inorganic scale crystals and the metal, so ...

Embodiment 2

[0021] Nano Al used in the embodiment of the present invention 2 O 3 The average particle size is 20 nm. The base fluid is deionized water. The performance evaluation of the scale inhibitor adopts the coupon method, that is, in the test solution, the water temperature of the scale-forming solution is increased to 50℃, and the scale inhibition rate is calculated according to the amount of scale on the surface of the coupon.

[0022] The scale inhibition rate of the scale inhibitor is calculated according to the following formula:

[0023] ×100%

[0024] among them: Is the scale inhibition rate;

[0025] Δ For the weight gain of the coupon when no scale inhibitor is added, mg;

[0026] Δ In order to add a certain scale inhibitor, the weight of the coupon, mg.

[0027] When containing 0, 10, 40, 100, 200, 1000 mg / L scale inhibitor (nano Al 2 O 3 In the base fluid of particles), the weight gains of the stainless steel coupons after the fouling experiment were 41.0, 20.9, 36.1, 14.7, 6...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com