Preparation method of electrochromic liquid crystal thin film material

An electrochromic and liquid crystal thin film technology, which is applied in the direction of liquid crystal materials, color-changing fluorescent materials, chemical instruments and methods, etc., can solve problems such as not easy to bend, poor film-forming property, and difficult production, and achieve easy processing, good film-forming property, The effect of increasing compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A preparation method of an electrochromic liquid crystal film, the specific steps are as follows:

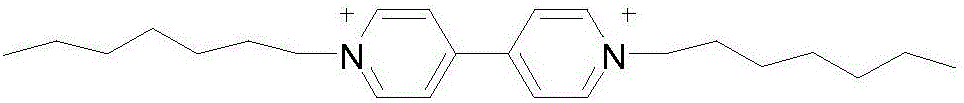

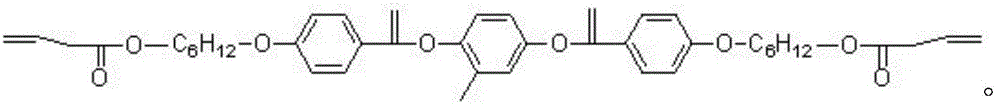

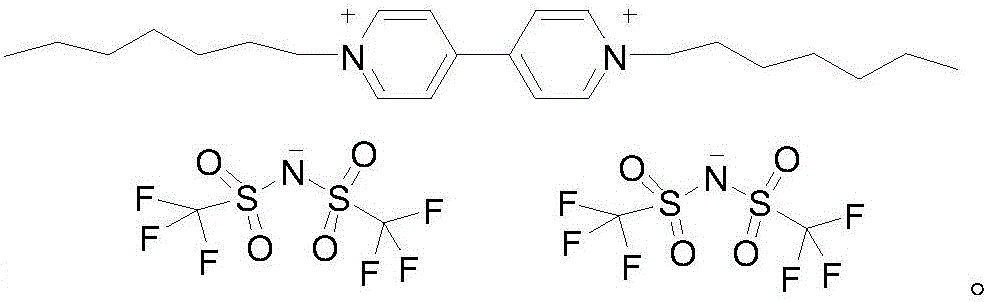

[0025] Step 1: Weigh viologen compounds, nematic liquid crystals, ultraviolet polymerizable monomers, spacer particles and photoinitiators according to the mass fraction of 3%: 80%: 15%: 1.5%: 0.5%, respectively;

[0026] Step 2: mixing the viologen compound, nematic liquid crystal, ultraviolet polymerizable monomer and spacer in step 1, and stirring evenly to obtain a mixture;

[0027] Step 3: Add the photoinitiator in Step 1 to the mixture in Step 2, and stir evenly to obtain the light-introducing mixture;

[0028] Step 4: Pour the light-absorbing mixture obtained in Step 3 between the polyester films coated with a conductive layer, squeeze it with a roller, and then put it under a light intensity of 3mw / cm 2 Radiation polymerization was carried out under ultraviolet light for 15 minutes to obtain a flexible electrochromic liquid crystal film material.

Embodiment 2

[0030] A preparation method of an electrochromic liquid crystal film, the specific steps are as follows:

[0031] Step 1: Weigh viologen compounds, nematic liquid crystals, ultraviolet polymerizable monomers, spacer particles and photoinitiators according to the mass fraction of 4%: 79%: 15%: 1%: 1%, respectively;

[0032] Step 2: mixing the viologen compound, nematic liquid crystal, ultraviolet polymerizable monomer and spacer in step 1, and stirring evenly to obtain a mixture;

[0033] Step 3: Add the photoinitiator in Step 1 to the mixture in Step 2, and stir evenly to obtain the light-introducing mixture;

[0034] Step 4: Pour the light-absorbing mixture obtained in Step 3 between the polyester films coated with a conductive layer, squeeze it with a roller, and then place it under a light intensity of 1.5mw / cm 2 Radiation polymerization was carried out under ultraviolet light for 20 minutes to obtain a flexible electrochromic liquid crystal film material.

Embodiment 3

[0036] A preparation method of an electrochromic liquid crystal film, the specific steps are as follows:

[0037] Step 1: Weigh viologen compounds, nematic liquid crystals, ultraviolet polymerizable monomers, spacer particles and photoinitiators according to the mass fraction of 8%: 75%: 10%: 5%: 2%, respectively;

[0038] Step 2: mixing the viologen compound, nematic liquid crystal, ultraviolet polymerizable monomer and spacer in step 1, and stirring evenly to obtain a mixture;

[0039] Step 3: Add the photoinitiator in Step 1 to the mixture in Step 2, and stir evenly to obtain the light-introducing mixture;

[0040] Step 4: Pour the light-absorbing mixture obtained in step 3 between the polyester films coated with a conductive layer, squeeze it with a roller, and then put it under a light intensity of 5mw / cm 2 Radiation polymerization was carried out under ultraviolet light for 10 minutes to obtain a flexible electrochromic liquid crystal film material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com