High-purity nanometer aluminum oxide electrolytic bath

A nano-alumina, electrolytic cell technology, applied in the field of electrolytic cells, can solve the problems of heat leakage, electrolyte leakage, waste of energy, etc., and achieve the effect of preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

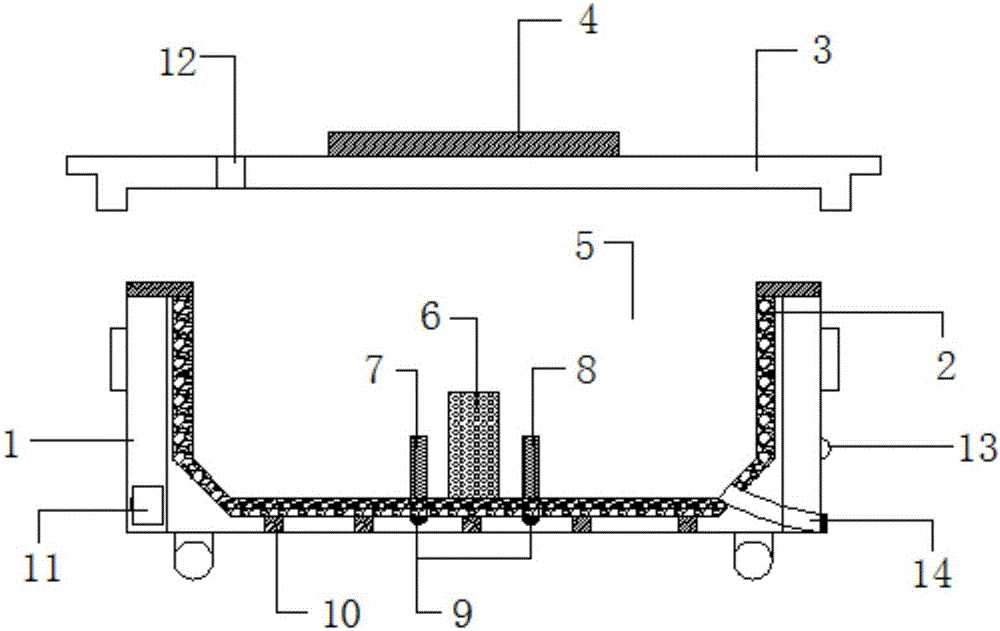

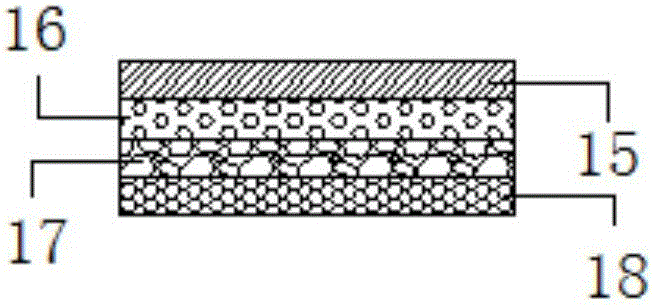

[0024] Example: see Figure 1-2 , a high-purity nano-alumina electrolytic cell of the present invention comprises a top cover 3, a tank body 1, a placement tank 5 and a reinforcement layer 2, the top cover 3 is made of transparent hard silica gel, and the top cover 3 is connected to the The solar cell panel 4 is detachably connected, the top cover 3 is provided with a water inlet 12 on one side, and the two ends of the top cover 3 are provided with convex plates to facilitate the movement of the top cover 3, and the top cover 3 and the top of the tank body 1 can be Mobile connection, the connection between the top cover 3 and the tank body 1 is provided with a sealing tape, the transparent hard silica gel has high hardness, and the inside can also be observed, and the sealing tape can prevent the electrolyte from leaking out, and the tank body 1 is made of steel plate and the two ends of the tank body 1 are provided with handles to facilitate the movement of the tank body 1. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com