Furniture paint

A furniture and titanium dioxide technology, applied in the field of paint, can solve the problems of decreased comprehensive performance and single function of water-based paint, and achieve the effects of isolating flames, improving photocatalytic efficiency, and broadening the spectral response range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

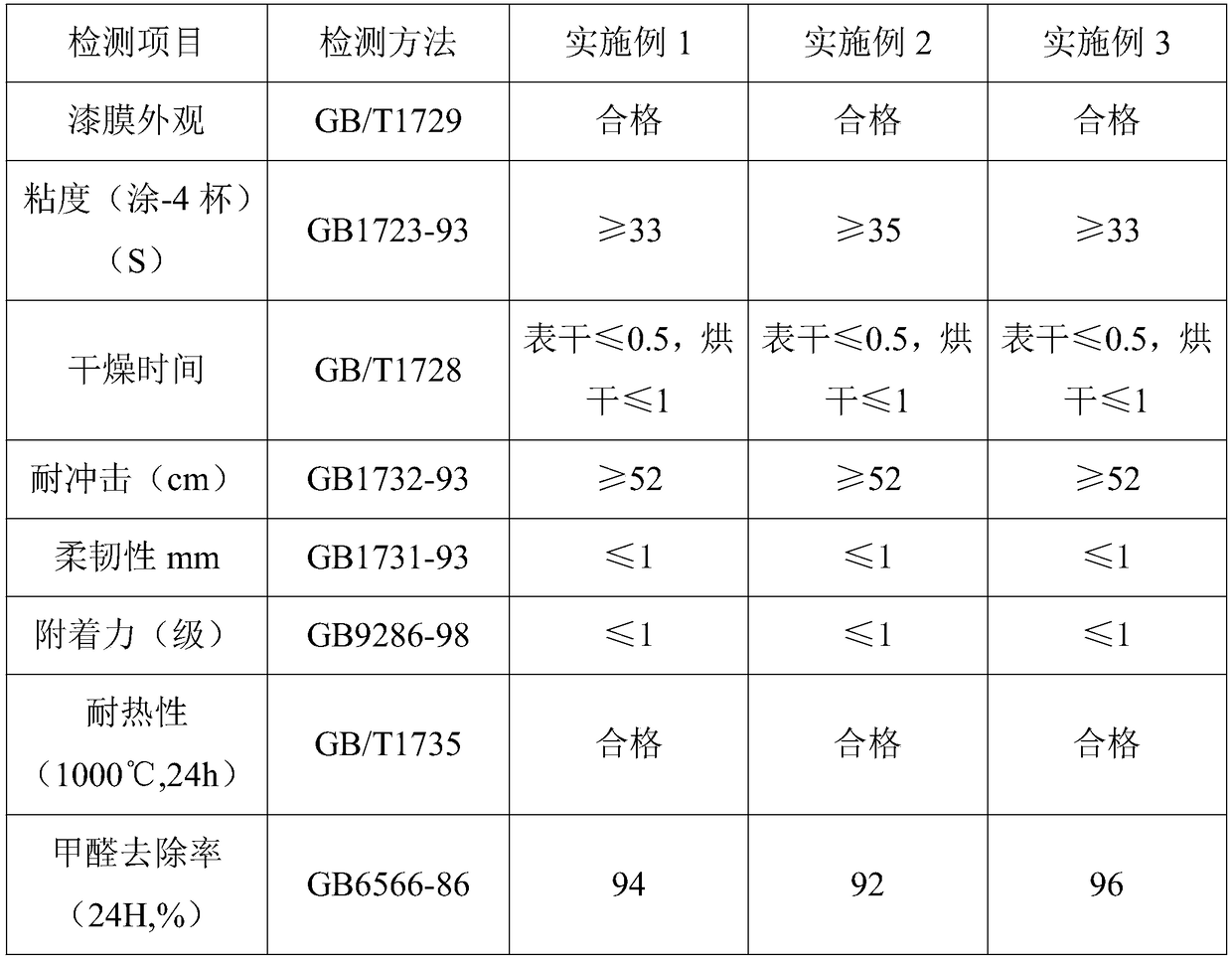

Examples

Embodiment 1

[0021] A furniture paint, calculated in parts by weight, comprising the following components:

[0022] 45 parts of water-based polyurethane resin, 20 parts of acrylate emulsion, 6 parts of water-based epoxy resin, 12 parts of magnesium aluminum hydrotalcite, 4 parts of modified titanium dioxide, 6 parts of dispersant and 50 parts of water.

[0023] The preparation method of modified titanium dioxide comprises the following steps:

[0024] (1) Put titanium dioxide into an aqueous solution containing a mass concentration of 12% cetyltrimethylammonium bromide, stir and ultrasonically disperse to obtain dispersion A;

[0025] (2) Silicon carbide is added into the silica sol for ultrasonic dispersion to obtain dispersion B;

[0026] (3) After mixing the dispersion liquid A and the dispersion liquid B, they are fully mixed and ground, and then sintered by hot pressing at 300°C to obtain the modified titanium dioxide. The mass ratio of titanium dioxide to silicon carbide is 8:1, an...

Embodiment 2

[0028] A furniture paint, calculated in parts by weight, comprising the following components:

[0029] 40 parts of water-based polyurethane resin, 25 parts of acrylate emulsion, 8 parts of water-based epoxy resin, 8 parts of magnesium aluminum hydrotalcite, 6 parts of modified titanium dioxide, 2 parts of dispersant, 2 parts of anti-settling agent and 40 parts of water.

[0030] The preparation method of modified titanium dioxide comprises the following steps:

[0031] (1) Put titanium dioxide into an aqueous solution containing 8% cetyltrimethylammonium bromide, stir and ultrasonically disperse to obtain dispersion A;

[0032] (2) Silicon carbide is added into the silica sol for ultrasonic dispersion to obtain dispersion B;

[0033] (3) After mixing the dispersion liquid A and the dispersion liquid B, they are thoroughly mixed and ground, and then sintered by hot pressing at 400°C to obtain the modified titanium dioxide. The mass ratio of titanium dioxide to silicon carbide...

Embodiment 3

[0035] A furniture paint, calculated in parts by weight, comprising the following components:

[0036] 50 parts of water-based polyurethane resin, 15 parts of acrylate emulsion, 4 parts of water-based epoxy resin, 16 parts of magnesium aluminum hydrotalcite, 3 parts of modified titanium dioxide, 5 parts of dispersant, 5 parts of leveling agent and 60 parts of water.

[0037] The preparation method of modified titanium dioxide comprises the following steps:

[0038] (1) Put titanium dioxide into an aqueous solution containing 6% cetyltrimethylammonium bromide, stir and ultrasonically disperse to obtain dispersion A;

[0039] (2) Silicon carbide is added into the silica sol for ultrasonic dispersion to obtain dispersion B;

[0040] (3) After mixing the dispersion liquid A and the dispersion liquid B, they are thoroughly mixed and ground, and then sintered by hot pressing at 450°C to obtain the modified titanium dioxide. The mass ratio of titanium dioxide to silicon carbide is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com