Switching joint of upper-layer concrete column and lower-layer concrete filled steel tubular column and implementation method

A technology of steel tube concrete columns and concrete columns, which is applied in the field of structural columns, can solve problems such as too dense steel bars, difficult control of construction quality, and insufficient safety reserves, so as to reduce the number and type of steel bars, easy control of construction quality, and improve safety reserve effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

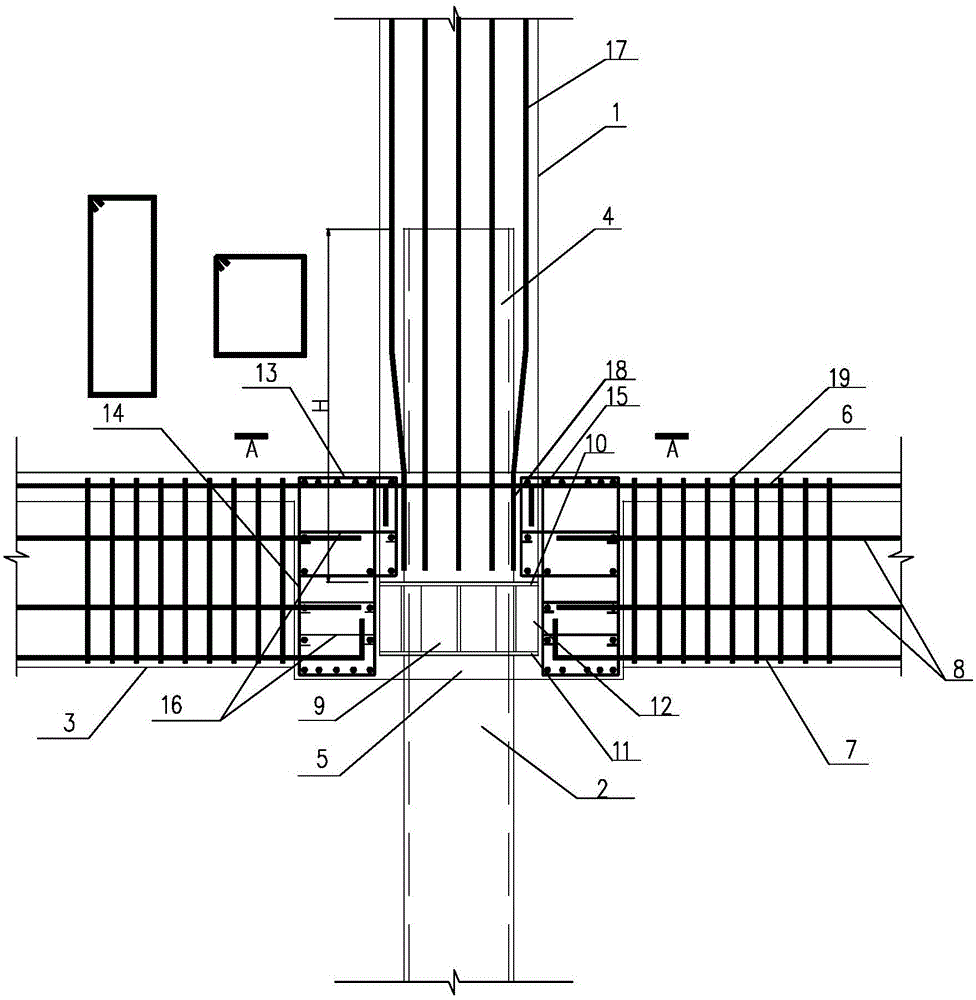

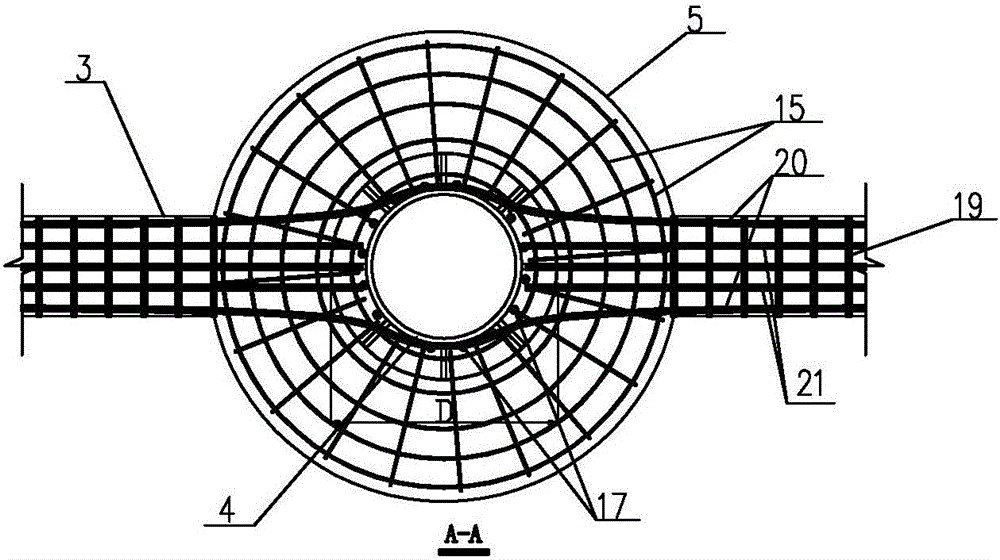

[0039] Such as figure 1 , figure 2As shown, the node is the junction of the upper concrete column 1 and the lower concrete-filled steel tube column 2, and the node area is located at the conversion position of the structural columns of different forms on the upper and lower floors of the building.

[0040] it includes:

[0041] Concrete-filled steel tube column 2 on the lower floor, concrete column 1 on the upper floor, and concrete beam 3, the diameter of the concrete column 1 on the upper floor is larger than that of the concrete-filled steel pipe column 2, and the floor beam is a concrete beam 3;

[0042] The concrete ring beam 5 wraps the entire node core area, the concrete beam 3 on the floor is connected to the concrete ring beam 5, and the longitudinal reinforcement of the concrete beam 3 is anchored into the concrete ring beam 5;

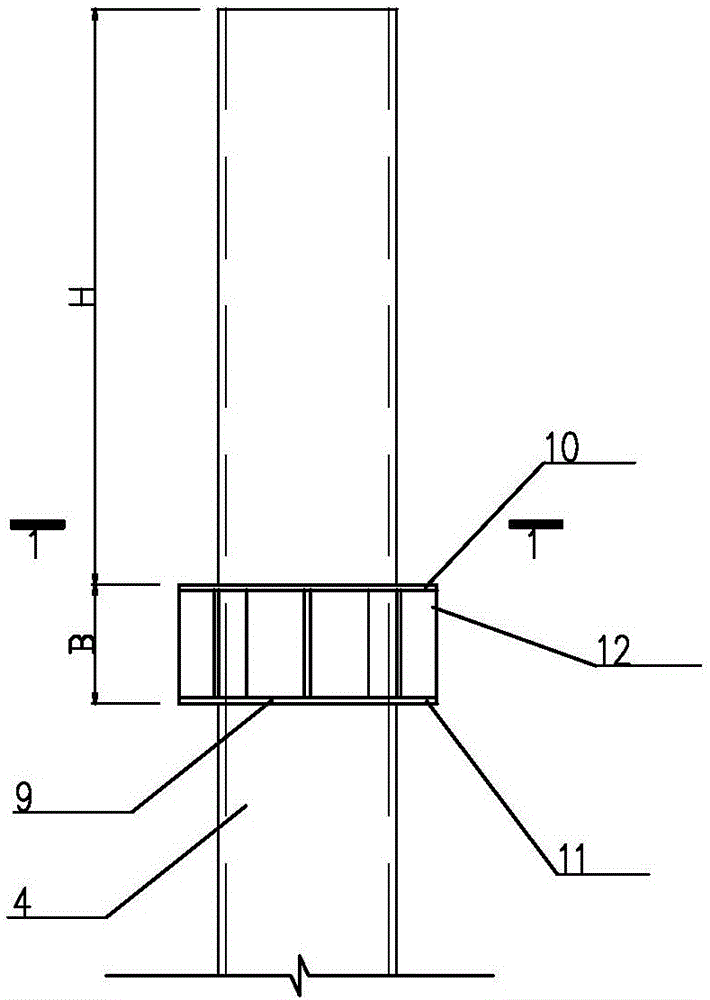

[0043] Such as image 3 As shown, the annular corbel 9 includes an upper ring plate 10, a lower ring plate 11, and a reinforcing rib 12...

Embodiment 2

[0051] Such as Figure 3-Figure 11 As shown, the conversion method of the joints of the upper large-diameter concrete column and the lower small-diameter steel pipe concrete column, the method includes the following steps:

[0052] 1 as image 3 , as shown in 4, the ring-shaped corbel is welded on the upper part of the steel pipe column. The annular corbel 9 is composed of an upper ring plate 10 , a lower ring plate 11 and a reinforcing rib 12 . The thickness of the steel plate of the annular corbel 9 is the same as the wall thickness of the steel pipe column 4, and the height B of the annular corbel 9 is calculated based on the difference in vertical force bearing capacity generated by the area difference between the upper concrete column 1 and the lower concrete filled steel pipe column 2. The diameter D of the annular corbel 9 is the same as that of the upper concrete column 1 . The elevation of the lower ring plate 11 of the annular corbel 9 is the same as that of the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com