A method and system for detecting micro-defects on the surface and subsurface of bronze wares

A detection method and detection system technology, which is applied in the direction of optical testing flaws/defects, instruments, measuring devices, etc., can solve problems such as inability to give three-dimensional size information, inability to use, bronze corrosion, etc., and achieve the effect of real-time online non-destructive testing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing and embodiment the present invention is described in further detail:

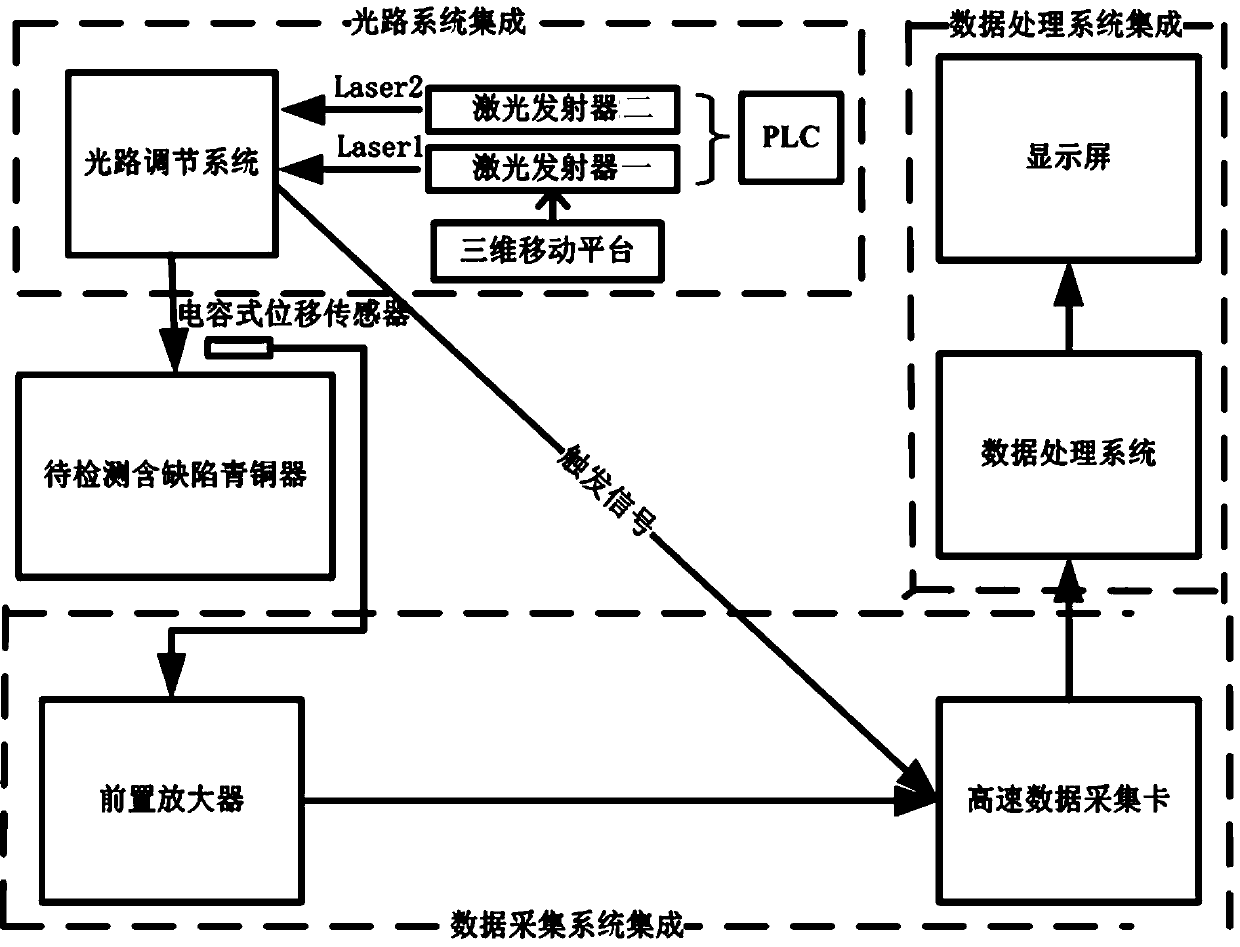

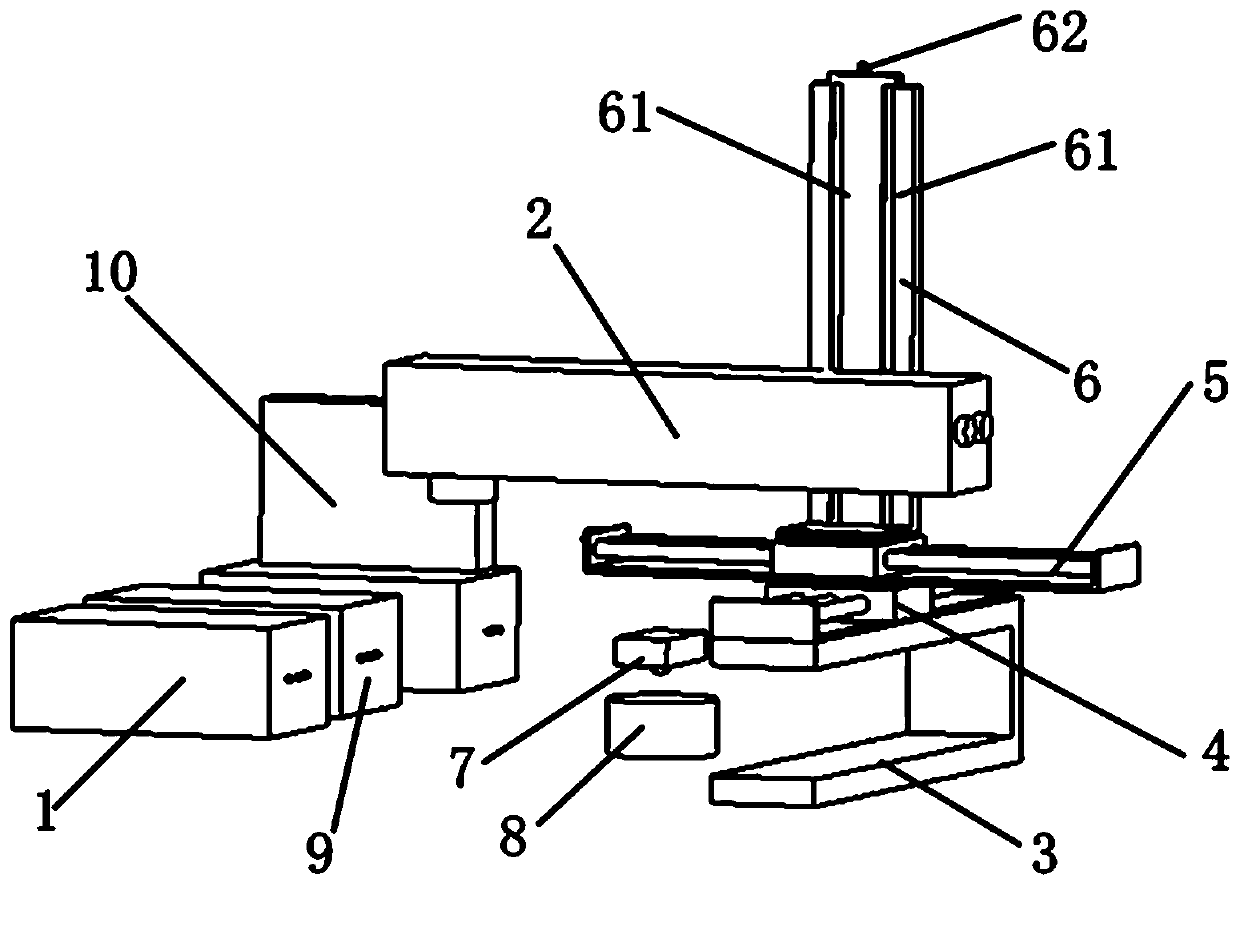

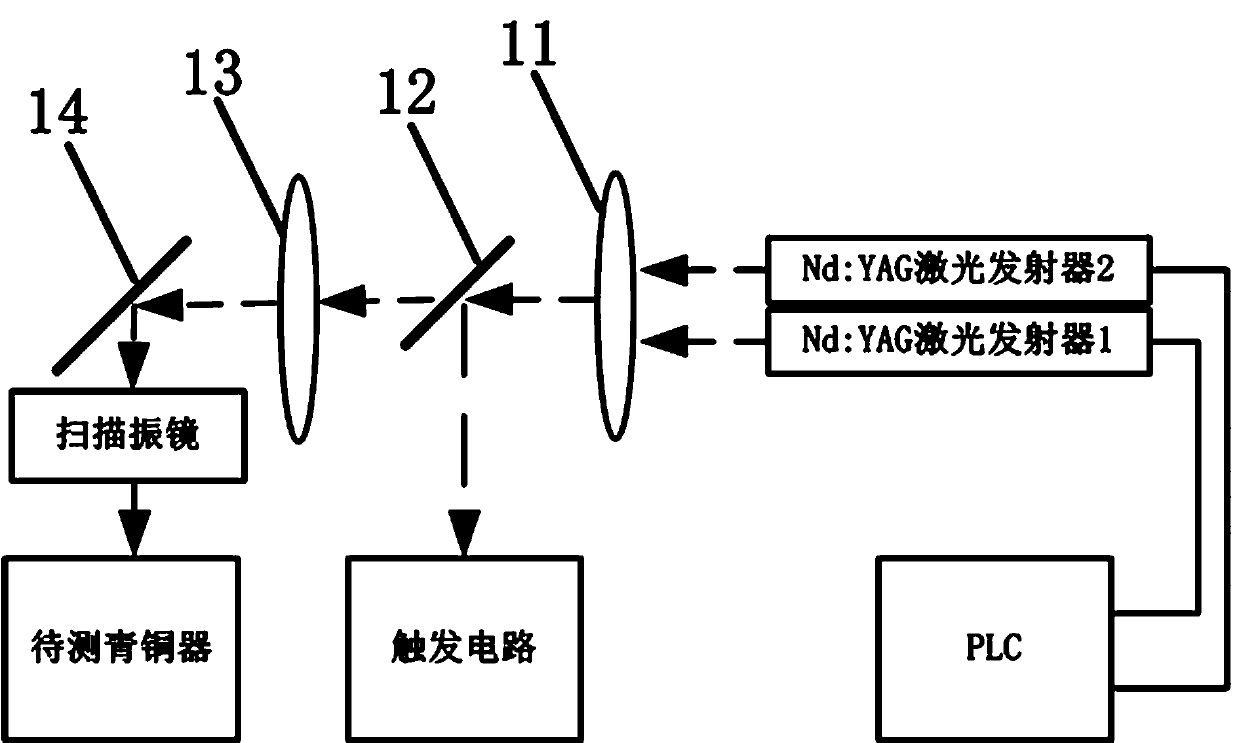

[0036] refer to Figure 1-6 :

[0037] The optical path system integration includes a U-shaped ground frame 3, a three-dimensional mobile platform, a PLC1 for controlling lasers, and a control cabinet 2 integrating two laser transmitters, an optical path adjustment system and a scanning galvanometer. The three-dimensional mobile platform includes a Z-direction mobile Station 6, X-direction mobile station 4, Y-direction mobile station 5, the control cabinet 2 is fixed on the third mobile platform of the Z-direction mobile station 6 by bolts, and the Z-direction mobile station 6 is fixed on the Y-direction mobile station by bolts. Above the second mobile platform 51 of the platform 5, the Y-direction mobile platform 5 is fixed on the top of the X-direction mobile platform 4 by bolts, so that the control cabinet 2 can be moved in the three spatial directio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com