Overcurrent protection device

A protection device, overcurrent technology, applied in the direction of current-responsive resistors, resistors with positive temperature coefficients, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] A first sheet of PTC polymer material (as the first PTC polymer material layer) was prepared from formulation (1) comprising 1.175 g of HDPE (available from Taiwan Plastics Corporation; model number HDPE9002; The weight average molecular weight is 150,000g / mole; according to ASTM D-1238, at a temperature of 230°C and a load of 12.5kg, the melt flow rate is 45g / 10min), 1.175g of carboxylic acid anhydride grafted (carboxylicacidanhydride grafted) HDPE Polyethylene (available from DuPont; model MB100D; weight average molecular weight 80,000 g / mole; melt flow rate 75 g / 10 min at 230° C. with a load of 12.5 kg according to ASTM D-1238), 21.15g of PVDF (purchased from Arkema; model Kynar 761; melting point 170°C; temperature of 230°C and load of 12.5kg, melt flow rate of 3.0g / 10min), and 26.5g of carbon black particles [purchased From Columbia Chemical Company; Trade name Raven 430UB; Average particle size 82nm; DBP oil-absorption (DBP-oil absorption) is 75cc / 100g; Volatile...

Embodiment 7 and 8

[0059]

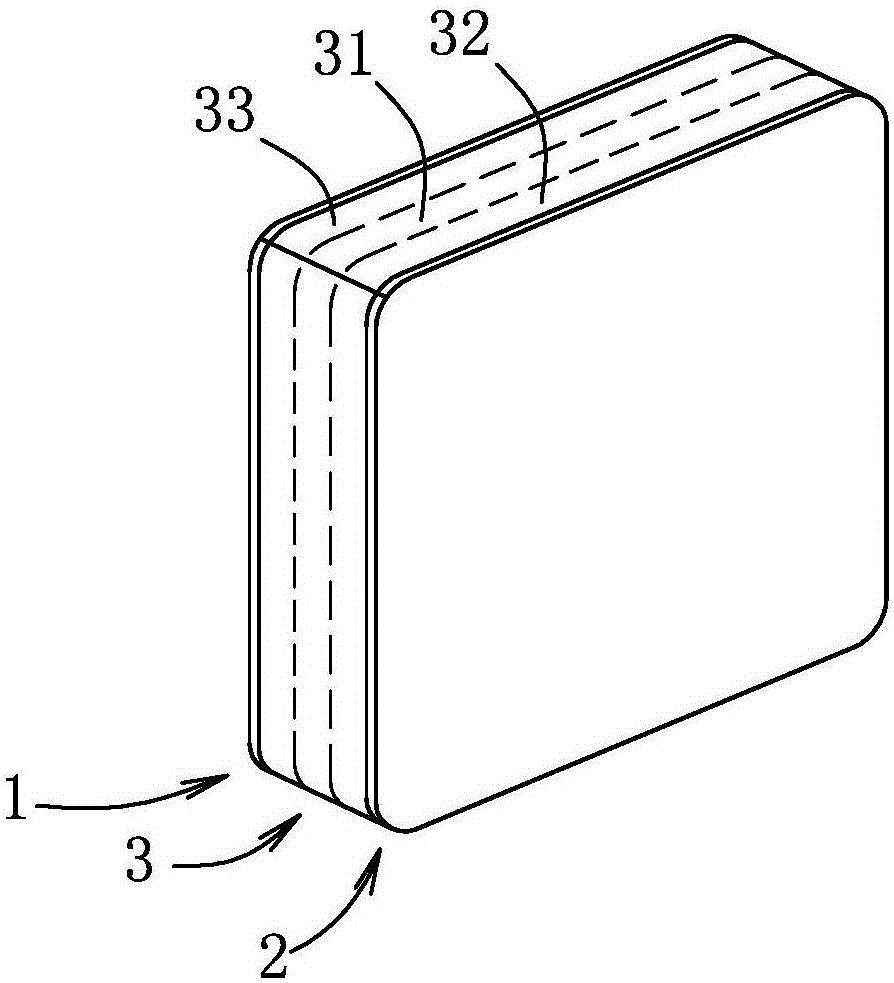

[0060] The preparation process and conditions of the test samples of Examples 7 and 8 (E7 and E8), except that each PTC laminate of Examples 7 and 8 also includes a third sheet of PTC polymer material, are the same as those of this Example 1 is similar.

[0061] The compositions of the PTC laminates of Examples 7 and 8 are shown in Table 2. The average resistances of the test samples of Examples 7 and 8 are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The melt flow rate | aaaaa | aaaaa |

| Weight average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com