Thin film transistor, manufacturing method thereof, display substrate and display device

A technology for thin film transistors and fabrication methods, applied in transistors, semiconductor/solid-state device manufacturing, electric solid-state devices, etc., can solve problems such as unstable threshold voltage, unfavorable applications, increased cost and process complexity, etc., and achieves improved stability, Improved uniformity and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] This embodiment provides a method for manufacturing a thin film transistor, the thin film transistor includes a gate, a source, a drain and an active layer, and the step of forming the active layer includes:

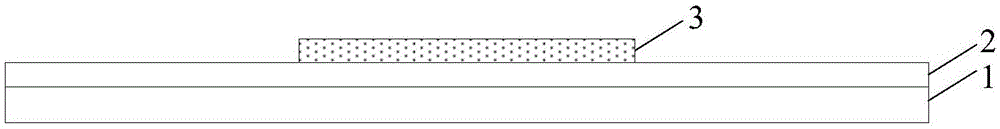

[0050] Form the graphics of the insulation layer;

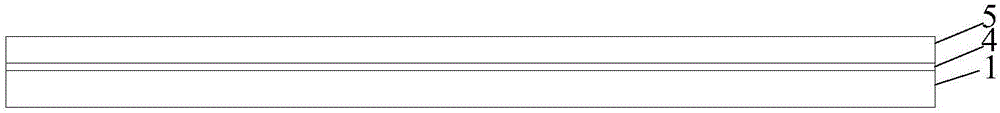

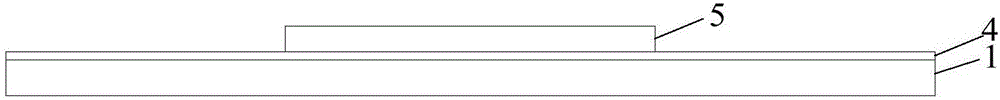

[0051] Forming a pattern of an amorphous silicon layer on the heat insulating layer, the pattern of the amorphous silicon layer including a first part located on the heat insulating layer and a second part beyond the heat insulating layer;

[0052] The pattern of the amorphous silicon layer is processed by laser annealing process to form the active layer composed of polysilicon.

[0053]In this embodiment, the pattern of the amorphous silicon layer includes a first part located on the thermal insulation layer and a second part beyond the thermal insulation layer. After the amorphous silicon layer is laser annealed, the second part beyond the thermal insulation layer is cooled It will nucleate first if it is fast...

Embodiment 2

[0089] This embodiment provides a kind of thin film transistor, which is manufactured by adopting the above-mentioned manufacturing method. The thin film transistor includes an active layer composed of polysilicon located on the heat insulating layer, and the active layer includes a part located on the heat insulating layer. And the part beyond the insulation layer.

[0090] Since the pattern of the amorphous silicon layer is formed on the thermal insulation layer during the formation of the active layer of the thin film transistor, the pattern of the amorphous silicon layer includes a first part located on the thermal insulation layer and a portion beyond the thermal insulation layer. The second part outside of the thermal insulation layer is processed by laser annealing process on the pattern of the amorphous silicon layer. After the laser annealing of the amorphous silicon layer, the second part beyond the thermal insulation layer is cooled faster and will first nucleate , ...

Embodiment 3

[0092] This embodiment provides a display substrate, including the above-mentioned thin film transistor. Since the carrier mobility of the thin film transistor is relatively high and the threshold voltage is relatively stable, compared with the existing display substrate, the performance of the display substrate of this embodiment will be more reliable.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com