Fabrication method of back incident high-reflection thin film system for neodymium glass laser

A neodymium glass, back-incidence technology, applied in the direction of lasers, laser components, phonon exciters, etc., can solve the problems of limited standing wave electric field optimization effect, difficult improvement, large electric field minimum value, etc., to achieve laser damage The effect of high threshold, low standing wave electric field strength, and reflection bandwidth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

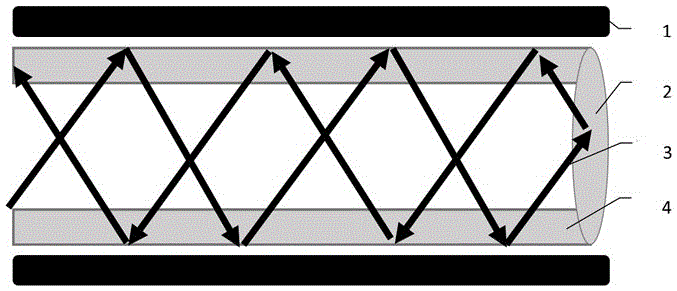

[0031] Taking the conventional parallel polarization state P-light back-incidence high-reflection film working angle—Brewster’s angle in the resonator configuration of the neodymium glass laser as an example, for the convenience of comparison. Such asfigure 1 shown.

[0032] Preparation:

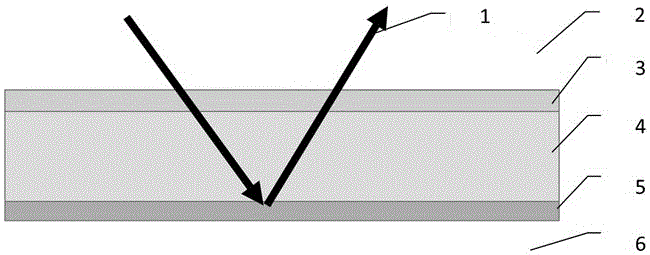

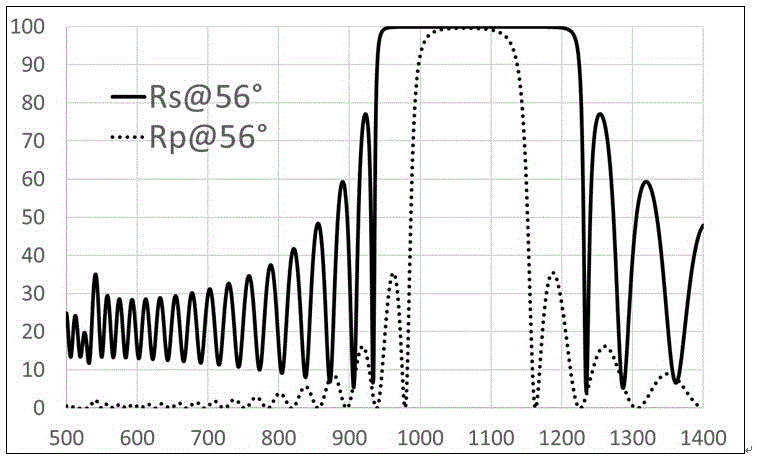

[0033] 1) Design the vertically polarized S-light AR coating and the vertically polarized S-light back-incidence high-reflection coating at the Brewster angle; the film structure of the vertically polarized S-light AR coating is [substrate|LHL|air], The film structure of the vertically polarized S-light back-lighting high-reflection film is [substrate|L(HL)^15|air]. where L represents a quarter of the optical thickness of the low refractive index material SiO 2 , H represents a quarter of the optical thickness of the high refractive index material HfO 2 , the working wavelength is 1053nm;

[0034] 2) Analyze and optimize the standing wave electric field. By changing the back-incidence hi...

Embodiment 2

[0046] Adopting the back-incidence high-reflection film system for vertically polarized S light proposed by the present invention can also make the resonant cavity configuration of the neodymium glass laser work at any angle other than the Brewster angle, and now take 45° as an example for illustration.

[0047] Preparation:

[0048] 1) Design a vertically polarized S-light AR coating at 45° incidence and a vertically polarized S-light back-incidence high-reflection film; the film structure of the vertically polarized S-light AR coating is [substrate|LHL|air], and the vertical polarization state The film structure of the S-light back-lit high-reflection film is [substrate|L(HL)^15|air]. where L represents a quarter of the optical thickness of the low refractive index material SiO 2 , H represents a quarter of the optical thickness of the high refractive index material HfO 2 , the working wavelength is 1053nm;

[0049] 2) Analyze and optimize the standing wave electric field...

PUM

| Property | Measurement | Unit |

|---|---|---|

| optical damage threshold | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com