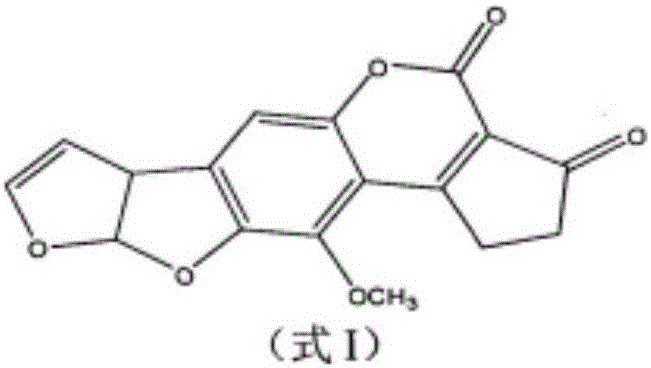

Aflatoxin irradiation degradation method

A technology of aflatoxin and aflatoxin, applied in the direction of food science, etc., can solve the problems of high cost of biochemical detoxification and difficulty in preparing highly active aflatoxin detoxification active substances, so as to improve the degradation effect and improve the degradation rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

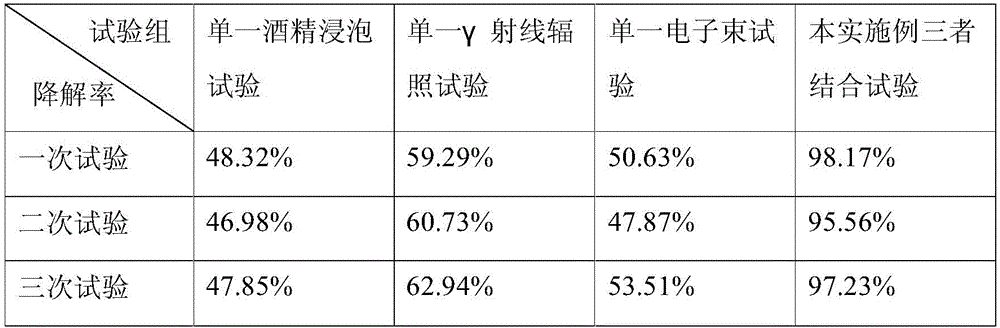

Embodiment 1

[0035] A method for irradiation degradation of aflatoxin, comprising the following steps:

[0036] Step 1, inoculate Aspergillus flavus ATCC11498 (purchased from American Culture Collection Center ATCC, No. 11498 bacterial strain) on the Chapei culture medium which has been sterilized at 120°C for 15min (Chape culture medium includes 2g of sodium nitrate, dipotassium cyanide phosphate 1g, potassium chloride 0.5g, magnesium sulfate 0.5g, ferrous sulfate 0.01g, sucrose 30g, agar 15g and water 1000ml), slope, temperature 25 ℃, humidity 45%, culture for 7 days, until the slope is covered with yellow-green bacteria When the mycelium is slightly sporulated, the spore suspension is made with sterile water.

[0037] Step 2. After the peanuts are irradiated with ultraviolet light for 10 minutes to sterilize, add the peanuts to the sterile water with a mass ratio of 1:1.5 between peanuts and sterile water, and then add 2 parts by volume of the spore suspension in step 1 to mix. Evenly, a...

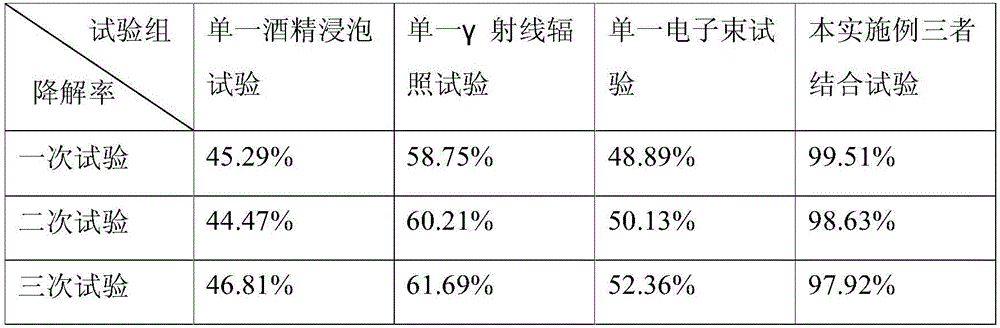

Embodiment 2

[0045] A method for irradiation degradation of aflatoxin, comprising the following steps:

[0046] Step 1. Inoculate Aspergillus flavus ATCC11498 (purchased from the American Culture Collection Center ATCC, No. 11498 strain) into the Chapei culture medium which has been sterilized at 125°C for 25min (Chape culture medium includes 2g of sodium nitrate, dipotassium cyanide phosphate 1g, potassium chloride 0.5g, magnesium sulfate 0.5g, ferrous sulfate 0.01g, sucrose 30g, agar 20g and water 1000ml), slope, temperature 30 ℃, humidity 55%, culture for 7 days, until the slope is covered with yellow-green bacteria When the mycelium is slightly sporulated, the spore suspension is made with sterile water.

[0047] Step 2. After sterilizing the peanut product under ultraviolet light for 15 minutes, add the peanut product to sterile water at a mass ratio of 1:2, and then add 3 parts by volume of spores in step 1. The suspension is mixed evenly, and cultured for 7 days at a temperature of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com