Biologic patch material for cardiac repair

A biological patch and heart technology, applied in the field of biomedical materials, can solve the problems of low mechanical strength, poor biocompatibility, and inability to arbitrarily make pathological parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0127] The preparation of embodiment 1 porous structure layer

[0128] Elastin is dissolved in phosphate buffer solution PBS (10mM sodium phosphate, 150mM sodium chloride, pH7.4), forms the solution that concentration is 100mg / ml, adds the mucopolysaccharide (as heparin) that concentration is 10mg / ml in solution ), and finally add a lysine cross-linking agent (such as bis (sulfosuccinimidyl suberate)) to 10mM, and mix quickly. Slowly add the prepared solution to the corresponding mold, transfer the mold to a 37°C incubator and let it stand for 16 hours until it is formed ( figure 1 ), thereby making a porous structure layer consisting of the first structure layer and the second structure layer, and, as Figure 4 As shown, the porosity of the first structural layer is different from that of the second structural layer.

Embodiment 2

[0129] The detection of embodiment 2 biological patch material porosity

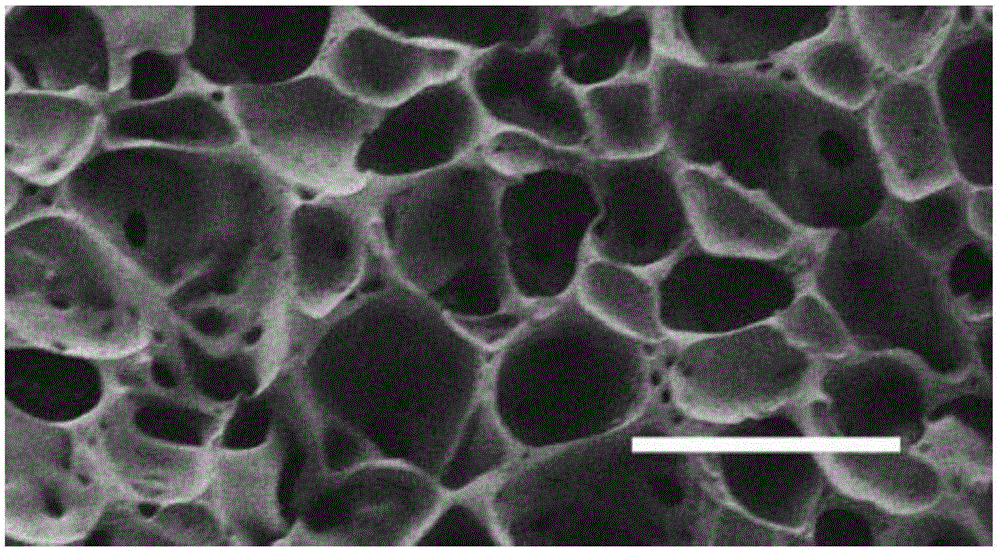

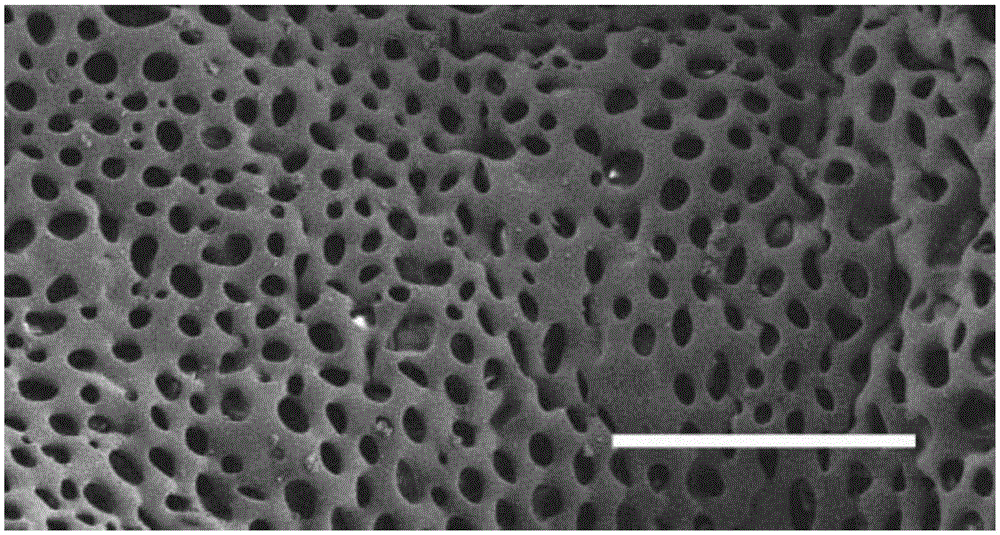

[0130] The bio-patch materials were observed by scanning electron microscopy (SEM) and micro-CT scanning in multi-layered sections in the vertical and horizontal directions.

[0131] Such as figure 2 and 3 As shown, the first porosity A1 is 1-10 μm, the second porosity A2 is 20-200 μm, the ratio A2 / A1 of the second porosity A2 to the first porosity A1≥5, preferably ≥8, more preferably Ground, ≥10. And, the thickness of the first structural layer is 0.01-0.05cm, the thickness of the second structural layer is 0.05-0.5cm, preferably, 0.1-0.25cm; the main surface area of the biological patch material is 10-80cm 2 , preferably 25-55cm 2 .

[0132] The results show that the first structural layer has a smaller porosity A1, which can prevent the loss of repair cells, and can also prevent the infiltration of inflammatory cells; the second layer has a larger porosity A2, which can load or accommodate car...

Embodiment 3

[0133] The mechanical performance test result of embodiment 3 biological patch materials

[0134] Use a uniaxial compression-relaxation test (such as Bose ELF3400, etc.) to determine the mechanical strength of the biological patch material. The patches were left in phosphate buffered solution for 5 hours before testing to avoid loss of elasticity due to dehydration of the patches. The entire mechanical strength test was performed in the presence of phosphate buffer solution to keep the patch wet. The test compresses and relaxes the patch with 50% tension at a speed of 30 μm per second, and records the compression value (mm) and load value (Newton) to calculate the final compression coefficient and energy loss rate.

[0135] The calculation method is as follows:

[0136] Compressibility coefficient: Values obtained from linear regression of compression and relaxation curves between 0-0.2 mm / mm.

[0137] Energy loss = 100% X (compression curve area - relaxation curve area) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com