Exhaust method for powder pressing formation

A technology of press molding and exhaust method, applied in the field of mold parts, can solve the problems of short service life of mandrels and connecting rods, and achieve the effect of long service life and ensuring uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

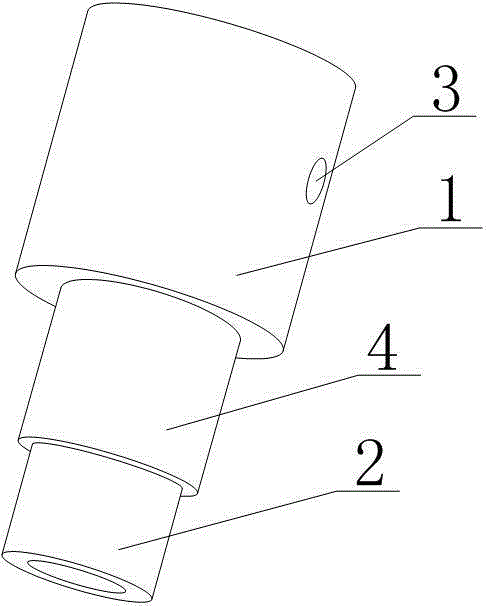

[0017] Such as figure 1 As shown, the exhaust method of powder compaction molding in the present invention includes a base 1, the base 1 is a part connected to the punching machine, driven by the punching machine, the base 1 is used to connect the punch 2 and the punching machine, the base The seat 1 is a cylinder as a whole, and its interior is a cylindrical cavity. A punch 2 is connected to the base 1. The punch 2 is a hollow cylinder, and its interior is a cavity structure. There is an exhaust hole 3 communicating with the inner cavity of the punch 2, a protective ring 4 is provided between the punch 2 and the base 1, the protective ring 4 is set on the punch 2, and the punch 2 and the base 1 A buffer zone is formed between the connecting parts to prevent the metal from flying around and hurting the human body after the explosion of the punch caused by excessive pressure when the product is pressed. Preferably, a plastic sleeve with certain elasticity is used as a protectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com