High-efficiency wave spring setting tempering technology

A wave spring and process technology, applied in the field of wave spring shaping and tempering technology, can solve problems such as complex stress, low production efficiency, and wave spring deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

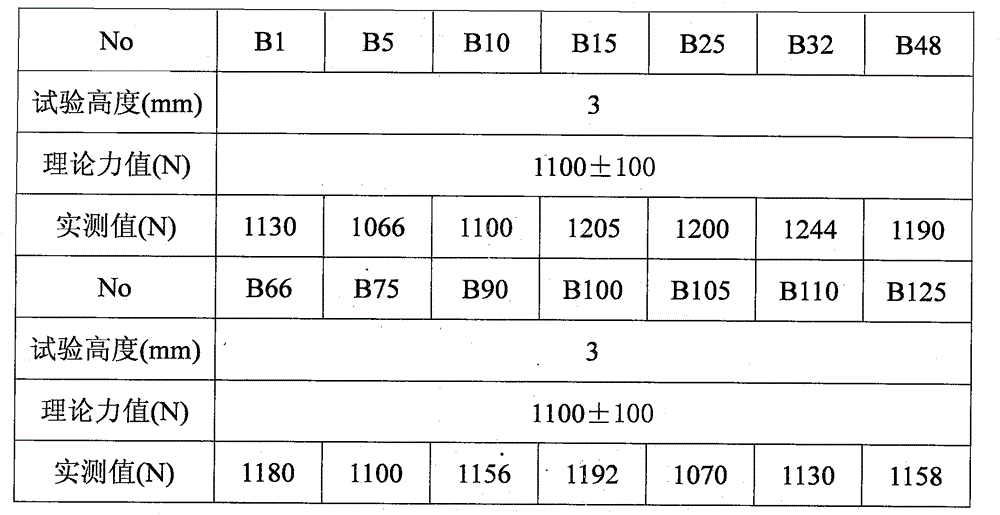

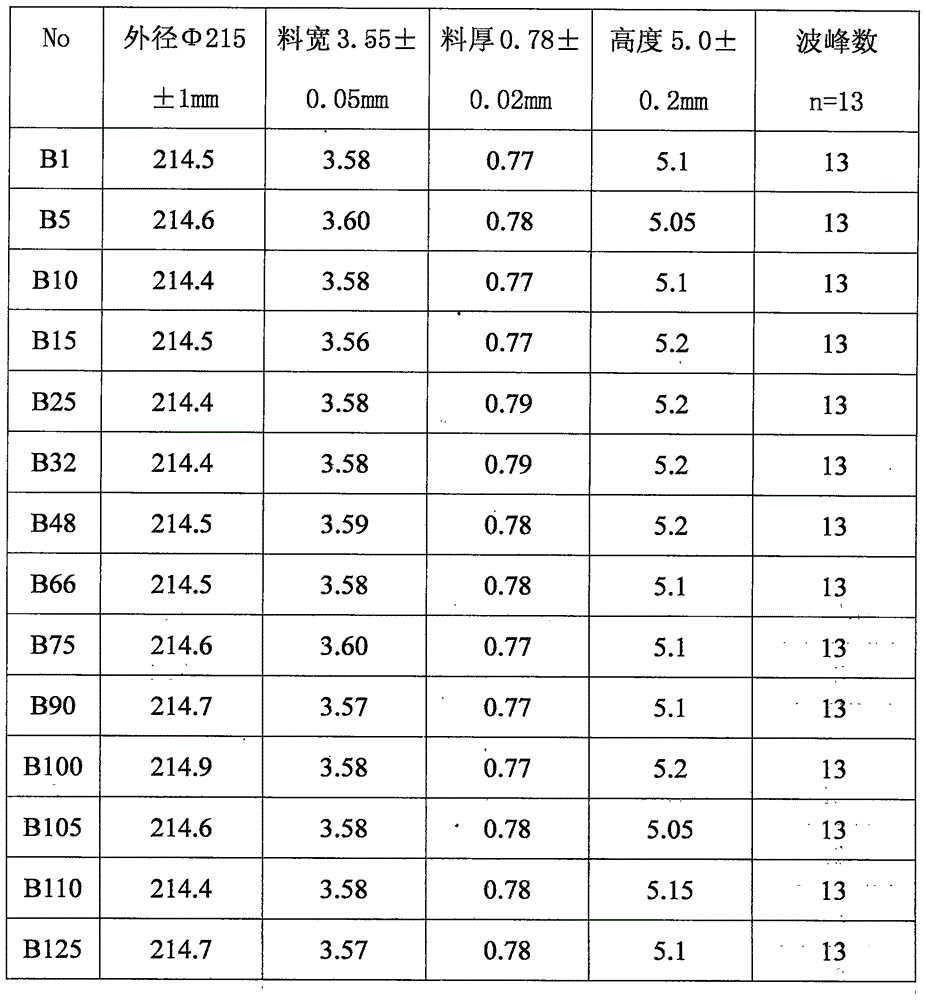

[0017] Implementation example: The process steps of wave spring shaping and tempering are as follows:

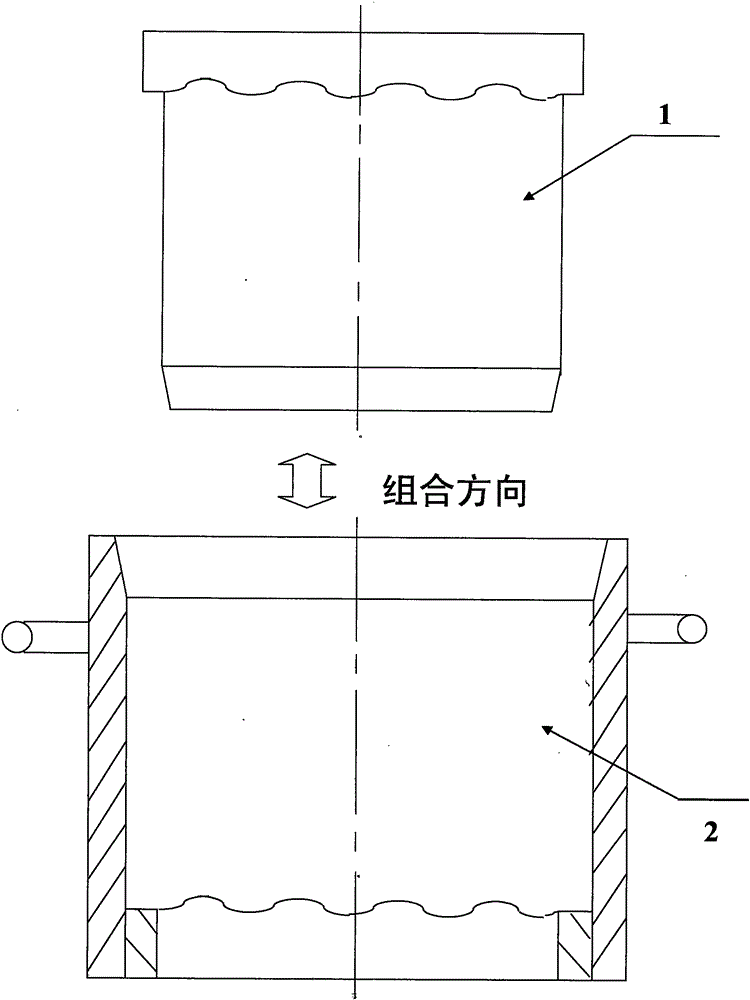

[0018] 1) Place the wave spring formed by pressing 65Mn cold-drawn spring steel wire into the mold A1 in a uniform position and direction (the mold structure is as follows: figure 1 shown);

[0019] 2) Put the mold B2 into the mold A1 filled with wave springs, press the wave spring tightly through the combined mold A1 and mold B2 under the pressure of not less than 8MPa on the hydraulic press and lock the combined mold die;

[0020] 3) Put the locked mold into the air tempering furnace and preheat at 380°C for 60 minutes;

[0021] 4) Take out the combined mold, put the combined mold on the hydraulic press again, and press and lock it with temperature at not less than 10MPa;

[0022] 5) Put the combined mold into the tempering furnace for secondary heating, keep it warm for 90 minutes at 420°C, and then take it out of the furnace and air cool to room temperature.

[0023]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com