Production method of boron cast iron cylinder sleeve

A technology of cast iron and cylinder liners, which is applied in the field of preparation of boron cast iron cylinder liners, can solve the problems of affecting the service life of the engine, affecting the fuel consumption of the combustion chamber, and failing to meet the needs of use, and achieves ingenious design, simple structure, good mechanical strength and hardness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with accompanying drawing.

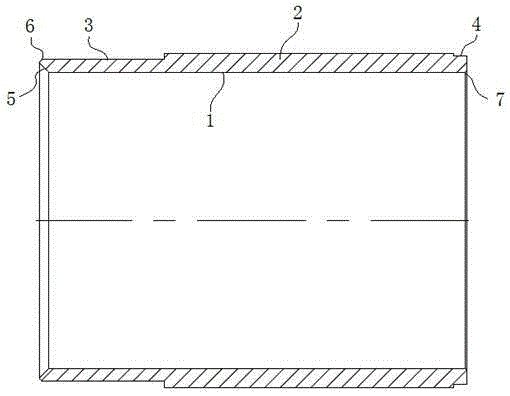

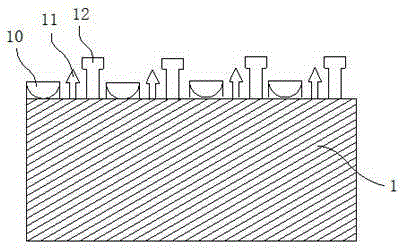

[0018] Such as figure 1 with figure 2 As shown, the preparation method of the boron cast iron cylinder liner mainly includes the cylinder liner body 1 and the cylinder liner outer surface 2. On the cylinder liner outer surface 2, there are three layers of protrusions with different heights, that is, the lower layer of protrusions. Protrusion 10, middle-level protrusion 11 and upper-level protrusion 12; Lower-level protrusion 10, middle-level protrusion 11 and upper-level protrusion 12 can be columnar, conical, inclined-plane, concave, corrugated, Regular or irregular shapes such as zigzag, spherical, umbrella, mushroom, etc., common or uncommon shapes, the three-layer protrusions can be the same shape or different protrusions or two of them are the same The protrusions are preferably different from each other, wherein the height of the lower protrusions 10 is less than 0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com