Automatic control circuit for welding with trailing peening

An automatic control circuit and control circuit technology, applied in the direction of program control, computer control, general control system, etc., can solve the problems of high cost and low control precision, and achieve the effect of accurate positioning, high control precision and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with drawings and embodiments.

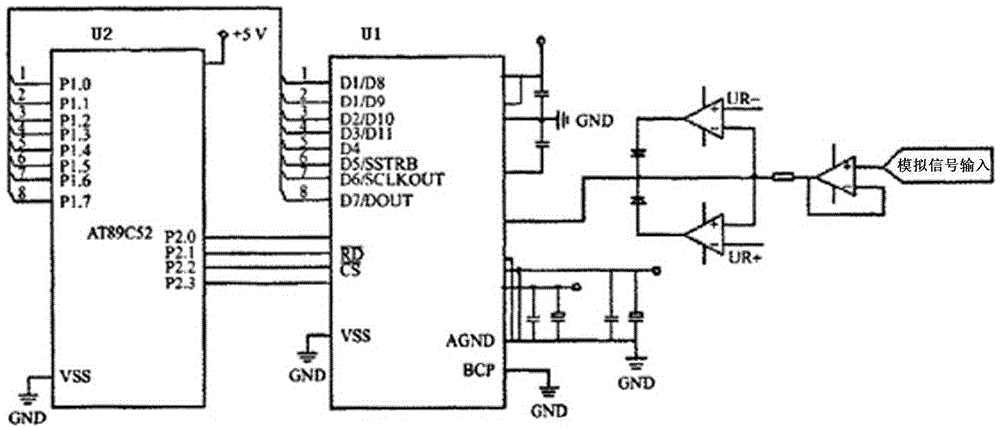

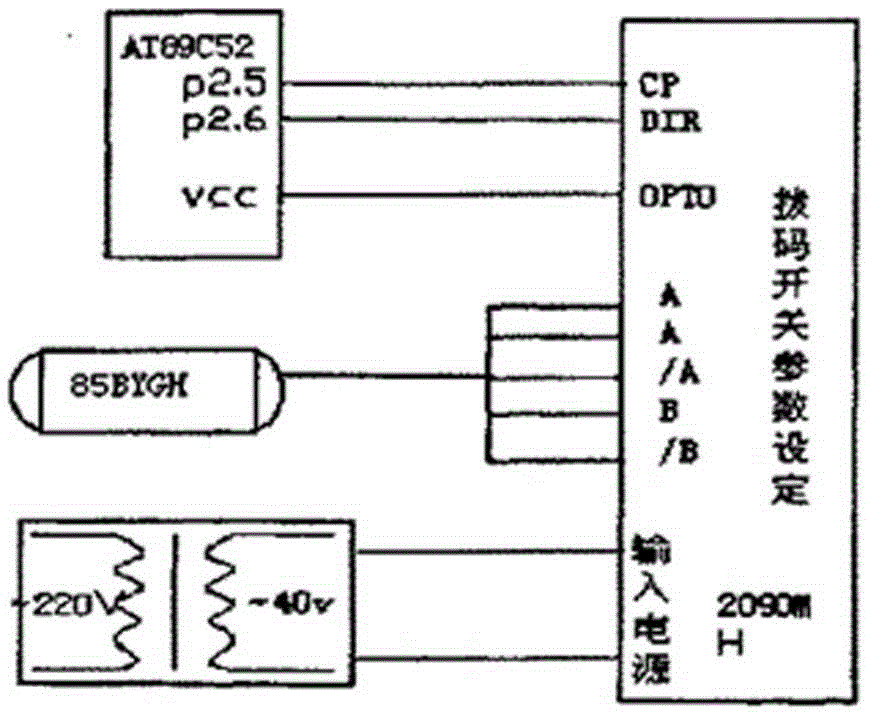

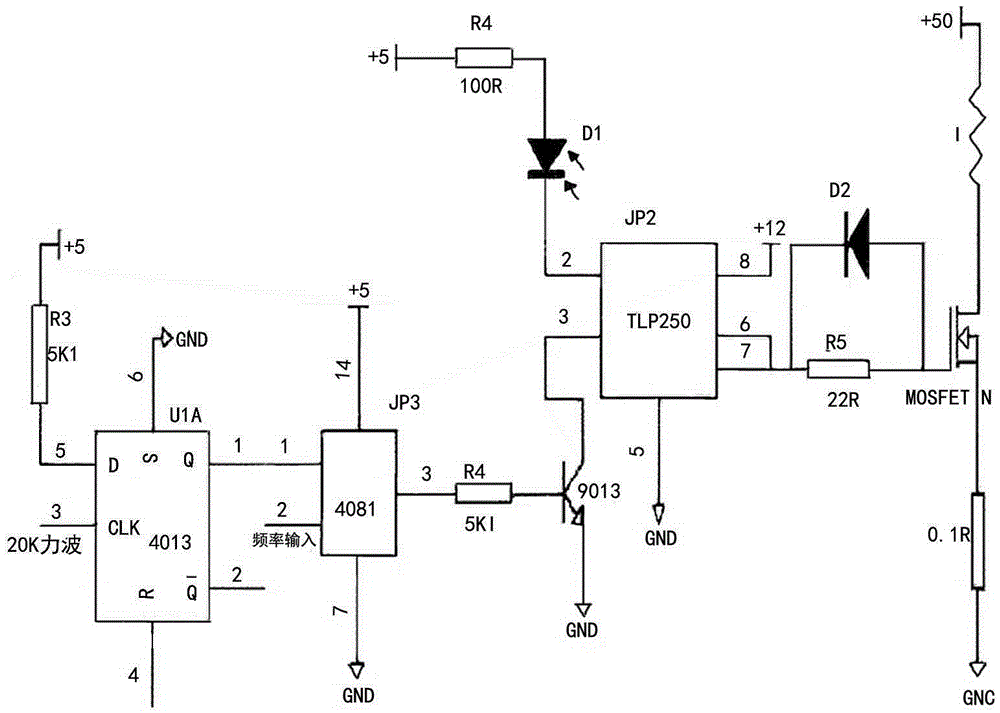

[0020] like figure 1 , the electromagnetic hammer and the thermometer are fixed together with a special fixture, the hammer head of the electromagnetic hammer and the welding torch are on the same plane perpendicular to the weldment, the hammer head and the temperature sensor point to the same point of the weld bead, and make the irradiation of the thermometer Diameter: smaller than the diameter R of the weld bead (generally r<0.5R). Start the thermometer at the same time as the welding starts, and transmit the weld bead temperature collected by the thermometer to the single-chip microcomputer through the A / D converter, compare it with the optimized temperature value stored in the single-chip microcomputer, and determine whether this position is suitable according to the comparison result hammer position. Then determine the appropriate hammering parameters (hammering ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com