Method and system for separating and recovering top gas of ethylene oxide stripping tower

A technology for separation and recovery of ethylene oxide, applied in chemical instruments and methods, preparation of organic compounds, organic chemistry, etc. The effect of reducing cooling water consumption, optimizing energy saving and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

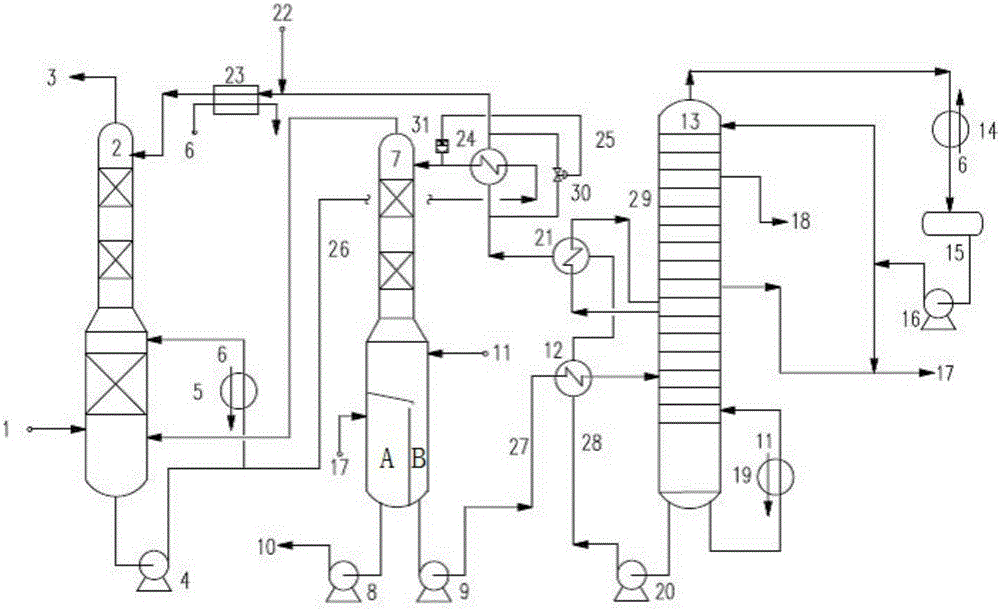

[0037] A kind of embodiment of the inventive method comprises the following steps:

[0038] (1), the ethylene oxide stripping tower top gas 1 is sent to the ethylene oxide reabsorption tower 2 of a low-pressure operation, in this tower, ethylene oxide is washed down again with reabsorbed water, thereby in the tower Top removal of light components gas 3. In order to ensure the reabsorption effect, the tower still needs to be provided with an external ethylene oxide reabsorption tower tower cooler 5, and the ethylene oxide reabsorption tower tower still pump 4 is used to transfer more than 70% of the tower still liquid through The ethylene oxide reabsorption tower tank cooler 5 is cooled and circulated back to the ethylene oxide reabsorption tower 2 to remove the heat in the absorption process. The light component gas 3 at the top of the ethylene oxide reabsorption tower 2 is circulated back to the ethylene oxide reaction system (not shown) after being pressurized; ℃ The feeds...

Embodiment approach

[0047] According to a preferred embodiment of the system of the present invention, the system can also include an ethylene oxide refining tower inlet / outlet heat exchanger 12 and an ethylene oxide refining tower side line reboiler 21; the second pipeline 27 And the third pipeline 28 can pass through the ethylene oxide refining tower inlet / outlet heat exchanger 12 so that heat exchange can be carried out between the second pipeline 27 and the third pipeline 28; The line 28 and the side line 29 drawn from the middle of the ethylene oxide refining tower 13 can pass through the side line reboiler 21 of the ethylene oxide refining tower so that the third line 28 and the side line 29 can be carried out Heat exchange; the feed preheater 24 can be located at the ethylene glycol feed stripper 7 side of the third pipeline 28, and the ethylene oxide refining tower inlet / outlet heat exchanger 12 can be located at the third On one side of the ethylene oxide reabsorption tower 2 of the pipe...

Embodiment

[0054] Such as figure 2 As shown, the gas phase (temperature 59°C) from the top of the ethylene oxide stripping tower enters the bottom of the ethylene oxide reabsorption tower, and the composition is as follows: ethylene oxide accounts for about 91wt%, water accounts for about 6.5wt%, and light components points (ethylene, CO 2 , methane, argon, etc.) accounts for about 2.5wt%. The tower is a packed tower (pressure range is 0.016-0.023MPaG, temperature range is 38-46°C), the number of theoretical plates is 15, and the reabsorbed water at about 38°C It is fed from the top of the tower, and the ethylene oxide in the gas phase feed is washed down again, thereby removing light components at the top of the tower. In order to ensure the effect of reabsorption, the tower still needs to be equipped with an external ethylene oxide reabsorption tower reactor cooler, and the ethylene oxide reabsorption tower tower reactor pump is used to transfer more than 70% of the tower reactor liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com