Coaxially split dual-core containing microfluid control nozzle and spinning device and spinning method

A microfluidic, coaxial technology, applied in the field of nanomaterials, can solve the problems of complex nanofiber structure and other problems, and achieve the effect of remarkable technological progress, simple application and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

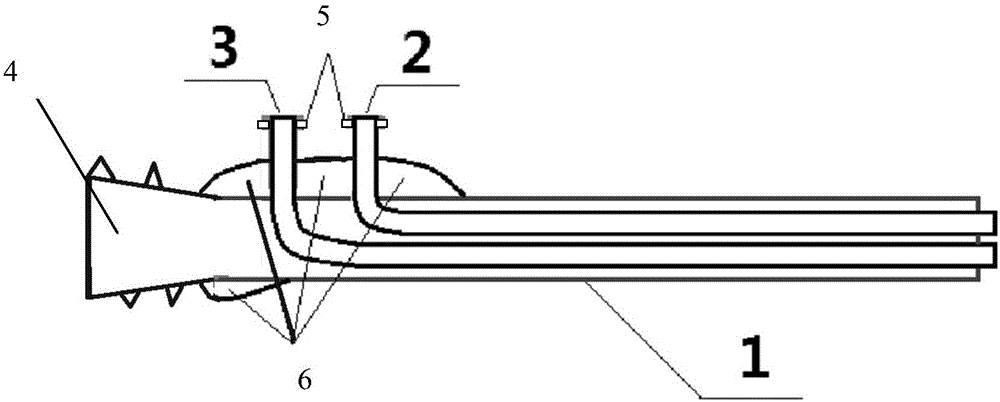

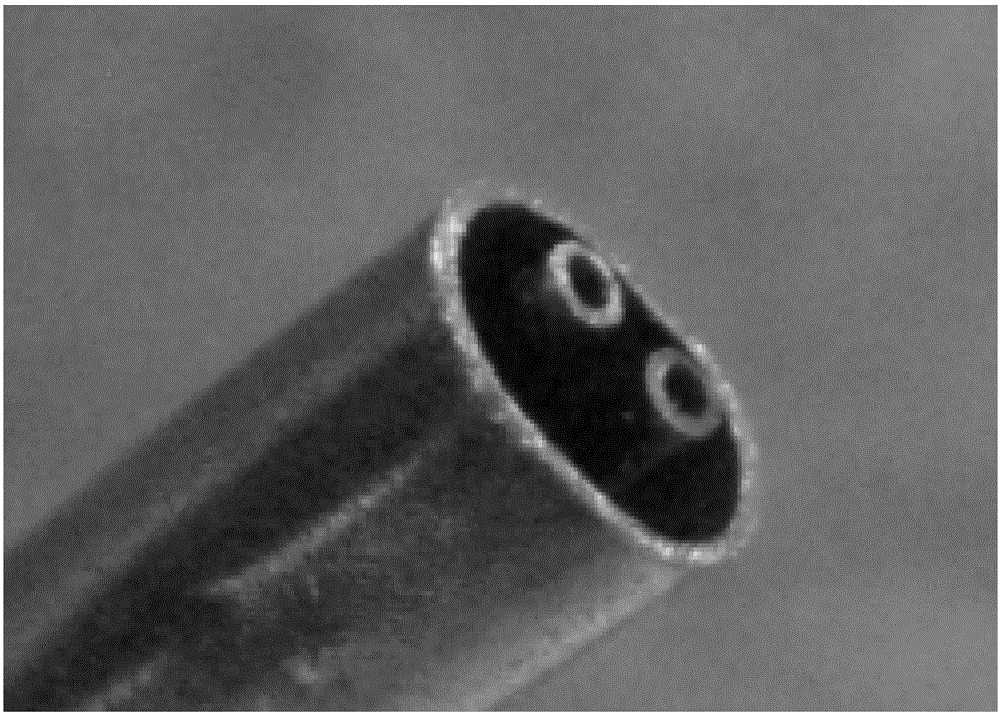

[0027] The present invention provides a coaxial microfluidic control nozzle containing split double cores, including a total capillary 1, a first curved capillary 2 and a second curved capillary 3; the first curved capillary 2 and the second curved capillary Two curved capillary tubes 3 are arranged side by side in the total capillary tube 1, and the curved ends of the first curved capillary tube 2 and the second curved capillary tube 3 pass through the side of the total capillary tube 1, so The other ends of the first curved capillary 2 and the second curved capillary 3 pass through the outlet end of the total capillary 1 and are flush with each other.

[0028] Further, the other ends of the first curved capillary 2 and the second curved capillary 3 pass through the outlet end of the total capillary 1 by 0.2 mm, and the first curved capillary 2 and the The distance between the second curved capillary 3 in the width direction is 0.2 mm, and the distance between the first curve...

Embodiment 2

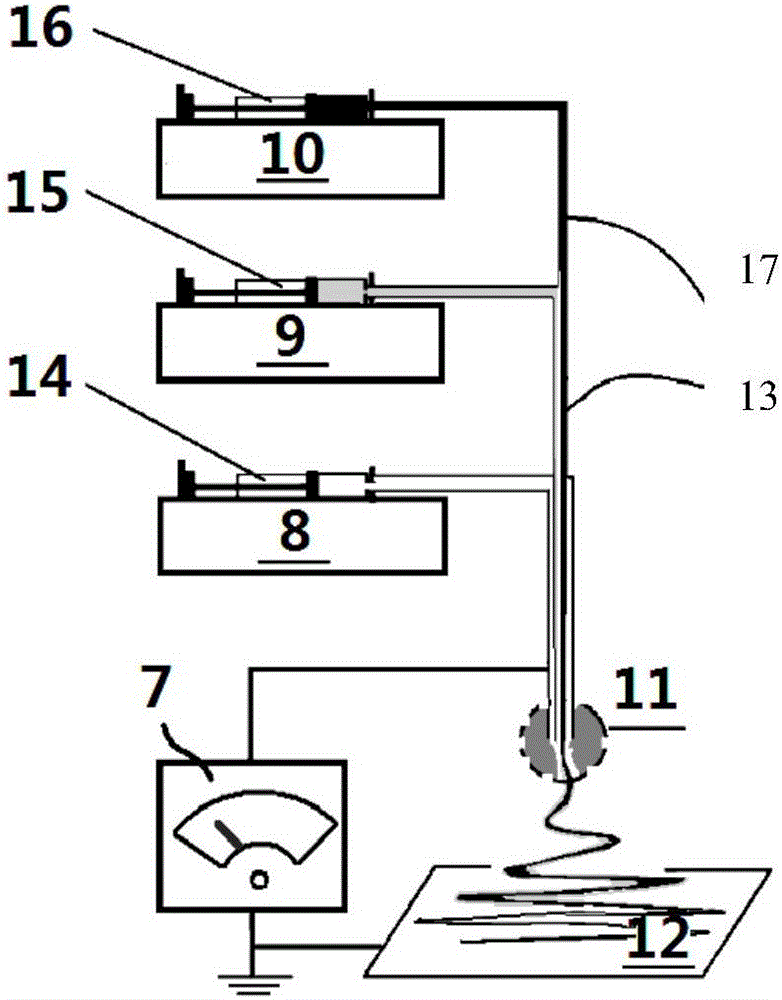

[0033] A high-voltage electrospinning device assembled using the nozzle of Example 1, its composition schematic diagram is as follows image 3 As shown, it includes a high-pressure generator 7, a first syringe pump 8, a second syringe pump 9, a third syringe pump 10, a coaxial microfluidic electrospray head 11 containing split double cores, a fiber receiving plate 12, a first high elastic Silicone hose 13, first syringe 14, second syringe 15, third syringe 16, second high elastic silicone hose 17.

[0034] A high-voltage electrospinning device with a coaxial microfluidic control nozzle containing split double cores is used to perform electrospinning on the three streams of fluids. The specific steps are: the first syringe 14 is installed in the first syringe pump 8, and the first syringe 14 A kind of sheath spinning liquid is added in, and the first syringe 14 is directly connected to the interface 4 of the coaxial microfluidic control nozzle 11 containing split double cores. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com