Fine core microstructure optical fiber interferometer sensor and temperature and strain detection method therefor

A technology of microstructured optical fiber and detection method, which is applied in the direction of converting sensor output, using optical devices to transmit sensing components, instruments, etc., which can solve the problems of sensitive optical fiber refractive index changes, sensors that cannot be used in liquid or high humidity environments, and complex calculations, etc. problem, to achieve the effect of simple composition structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

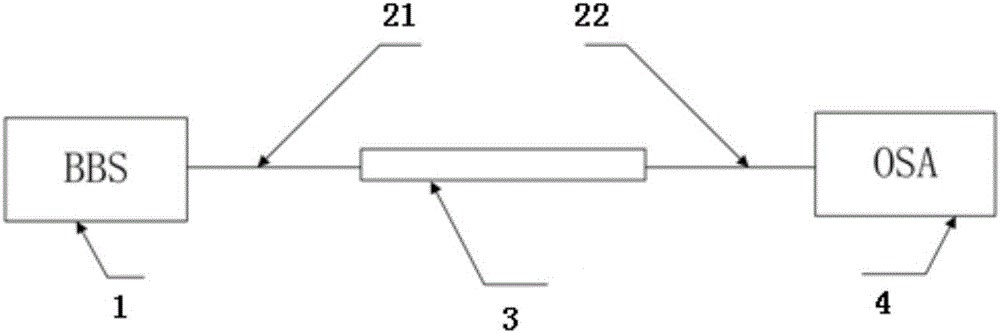

[0045] This embodiment discloses a fine-core microstructure optical fiber interferometer sensor, such as figure 1 As shown, it includes a broadband light source 1, a sensing head 3 and a spectrometer 4, the sensing head 3 is a fine-core microstructured fiber with an air cladding, and the broadband light source 1 is connected to one end of the thin-core microstructured fiber through an input single-mode fiber 21, The other end of the fine-core microstructured fiber is connected to the spectrometer through the output single-mode 22 fiber. The fine-core microstructured fiber is connected to the input single-mode fiber and the output single-mode fiber by fusion splicing, and both the input single-mode fiber and the output single-mode fiber are ordinary fibers.

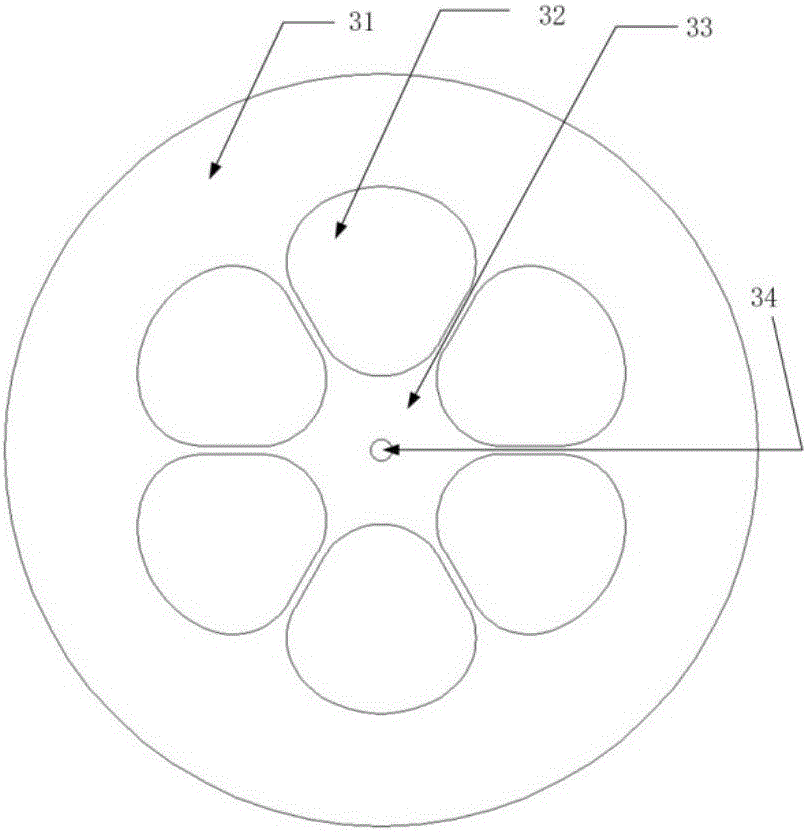

[0046] Such as figure 2 As shown, the fine-core microstructured optical fiber in this embodiment is respectively a core 34, an inner cladding 33, an air cladding and a pure silica outer cladding 31 from inside to the out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Core diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com