Multicoil ultrasonic guided-wave device of arbitrary frequency, and guided wave excitation method and receiving method thereof

An ultrasonic guided wave and multi-coil technology, which is applied in the generation of ultrasonic/sonic/infrasonic waves and the detection of response signals, etc., can solve the problems of low transduction efficiency, single mode and working frequency, etc., and solve the problem of low transduction efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

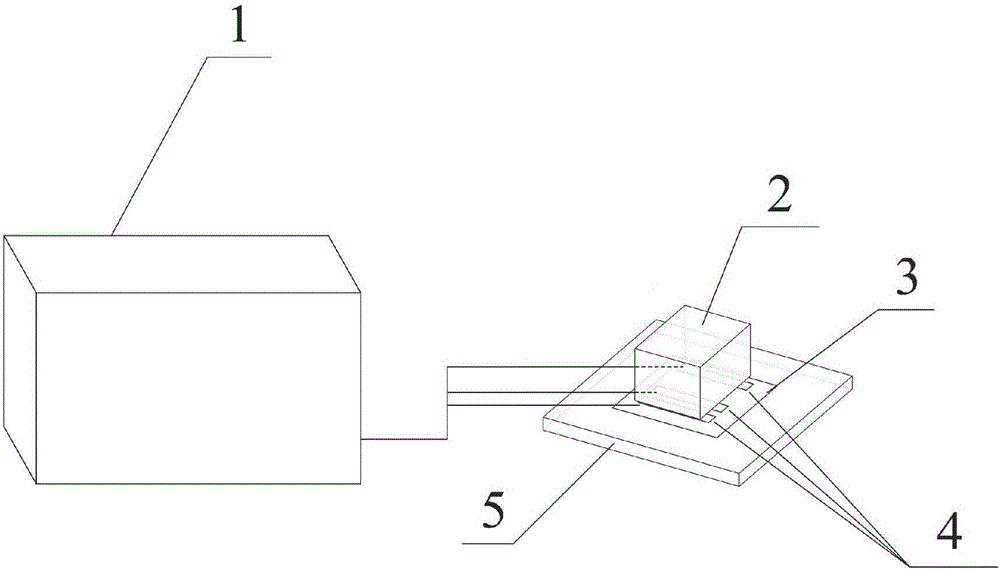

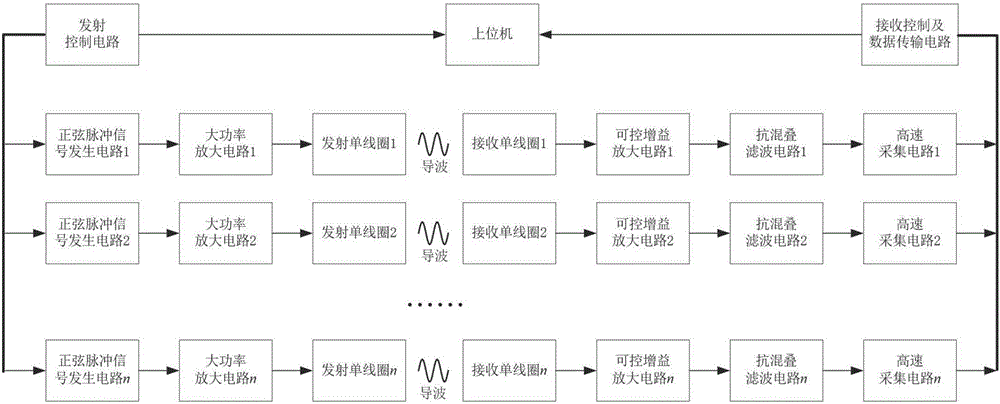

[0048] The invention belongs to the technical field of non-destructive testing, and specifically relates to a multi-coil ultrasonic waveguide device of any frequency, comprising a multi-channel excitation and receiving circuit device 1, a magnet 2, a magnetostrictive band 3 and a multi-coil combination 4, which solves the problem of the existing The problem of low transduction efficiency of the ultrasonic guided wave device, and the single type, mode and working frequency of the guided wave excited by the transducer.

[0049] The ultrasonic wave and the ultrasonic guided wave described in the present invention are actually the same, but the names are different.

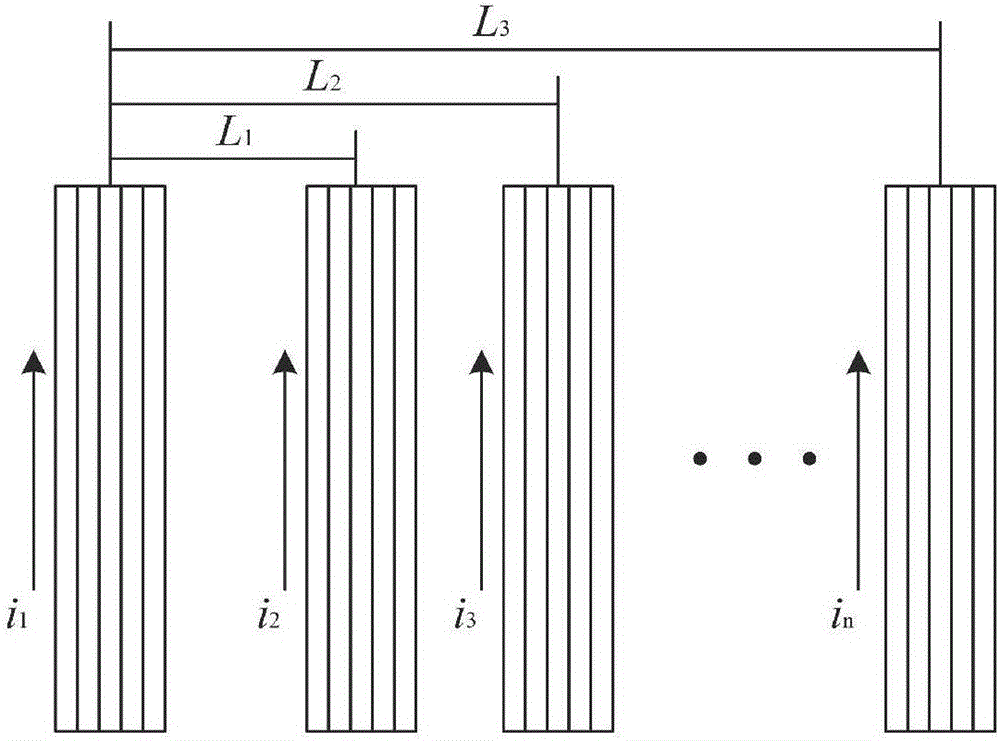

[0050] combine Figure 1-18 Specifically: one end of each single coil used to transmit ultrasonic waves in the multi-coil combination 4 is connected to one transmission circuit in the multi-channel excitation and receiving circuit device 1, and the other end is grounded; each single coil used to receive ultrasonic wav...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com