PCB with hollow cavity structure and manufacturing method therefor

The technology of a PCB board and a manufacturing method is applied to the PCB board with a cavity structure and its manufacturing field, which can solve problems such as difficulty and reduce transmission loss, and achieve the effects of simple manufacturing process, reduced loss, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

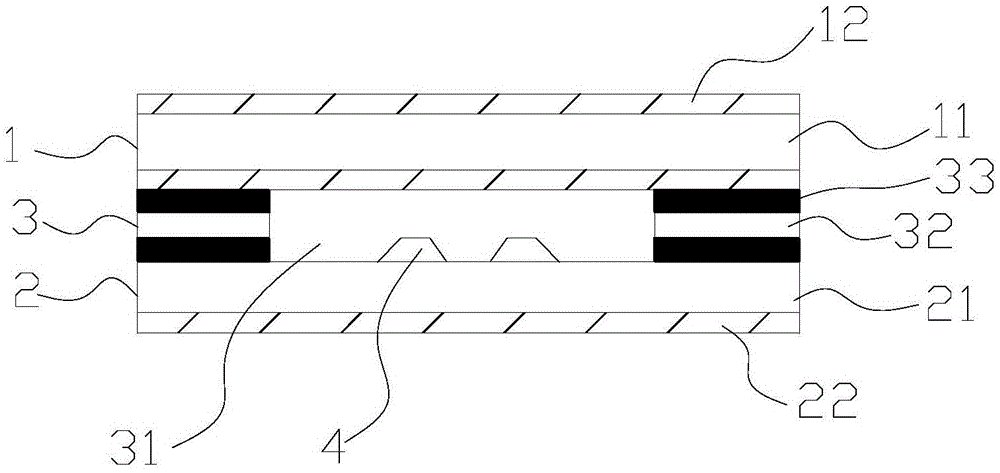

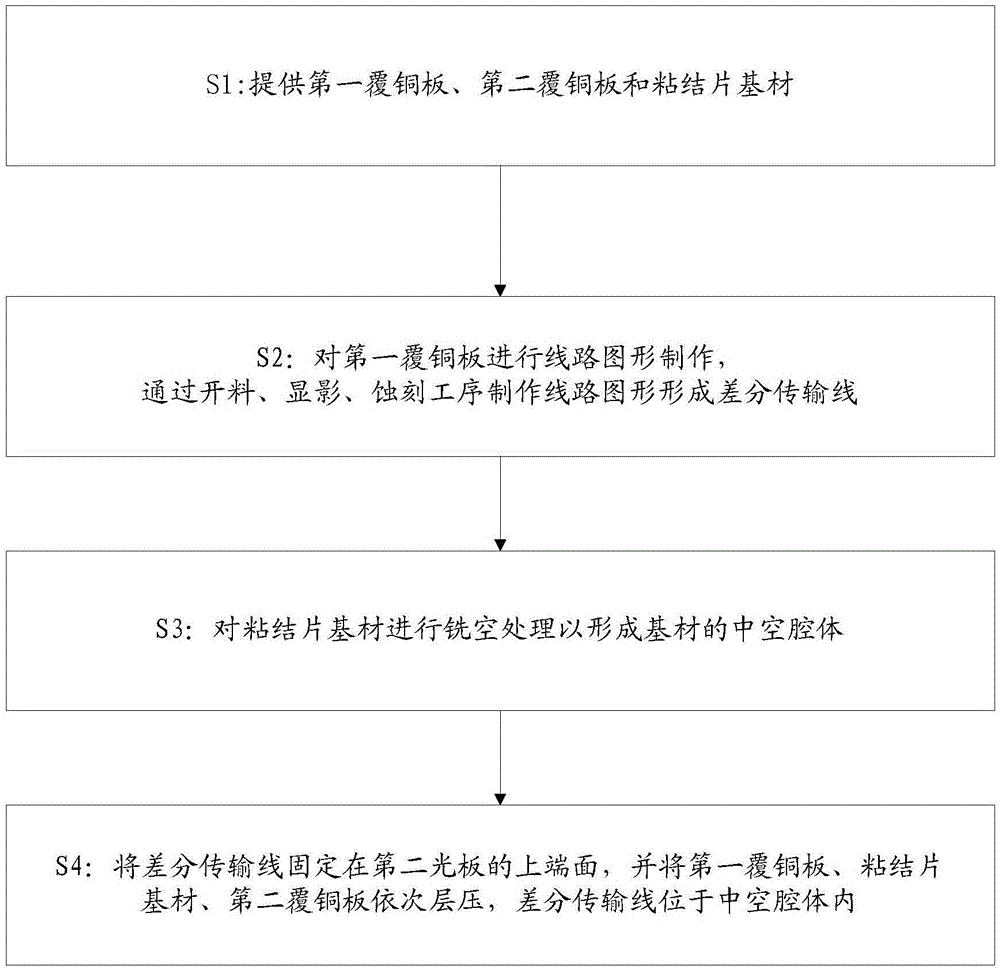

[0024] see figure 1 , the present invention provides a PCB board with a cavity structure, which is a multilayer board, including a first copper clad laminate 1, a second copper clad laminate 2, an adhesive sheet substrate 3 and a differential transmission line 4, the first copper clad laminate 1. The bonding sheet base material 3 and the second copper clad laminate 2 are arranged in sequence from top to bottom. The first copper clad laminate 1 comprises a first light plate 11, the upper end surface and the lower end surface of the first light plate 11 are respectively provided with a first copper clad layer 12; the second copper clad laminate 2 comprises a second light plate 21, the lower surface of the second light plate 21 The end face is provided with the second copper clad layer 22; The upper end surface of the bonding sheet 3 is milled to form a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com