Low foaming and high stability hydrotrope formulations

An aqueous solution and surfactant technology, applied in the field of aqueous solutions, can solve the problems of changing the circulation rate of formulations and closing the circulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0030] Low-foaming spray cleaning formulation with electrolytes

[0031] An aqueous solution consisting of: 65 wt% water; 10 wt% sodium hydroxide solution (50 wt% aqueous solution); 8 wt% ethylene oxide / propylene oxide / ethylene oxide block copolymer having a weight average molecular weight of approximately is 1750 g / mol, and ethylene oxide accounts for approximately 30 wt% of the block copolymer (e.g. TERGITOL TM L-62 polyether polyol nonionic surfactant (TERGITOL is a trademark of The Dow Chemical Company)); 4 wt% sodium carbonate; 3 wt% sodium metasilicate and 10 wt% hydrotropes identified in Table 1, wherein wt % is based on the weight of the total aqueous solution.

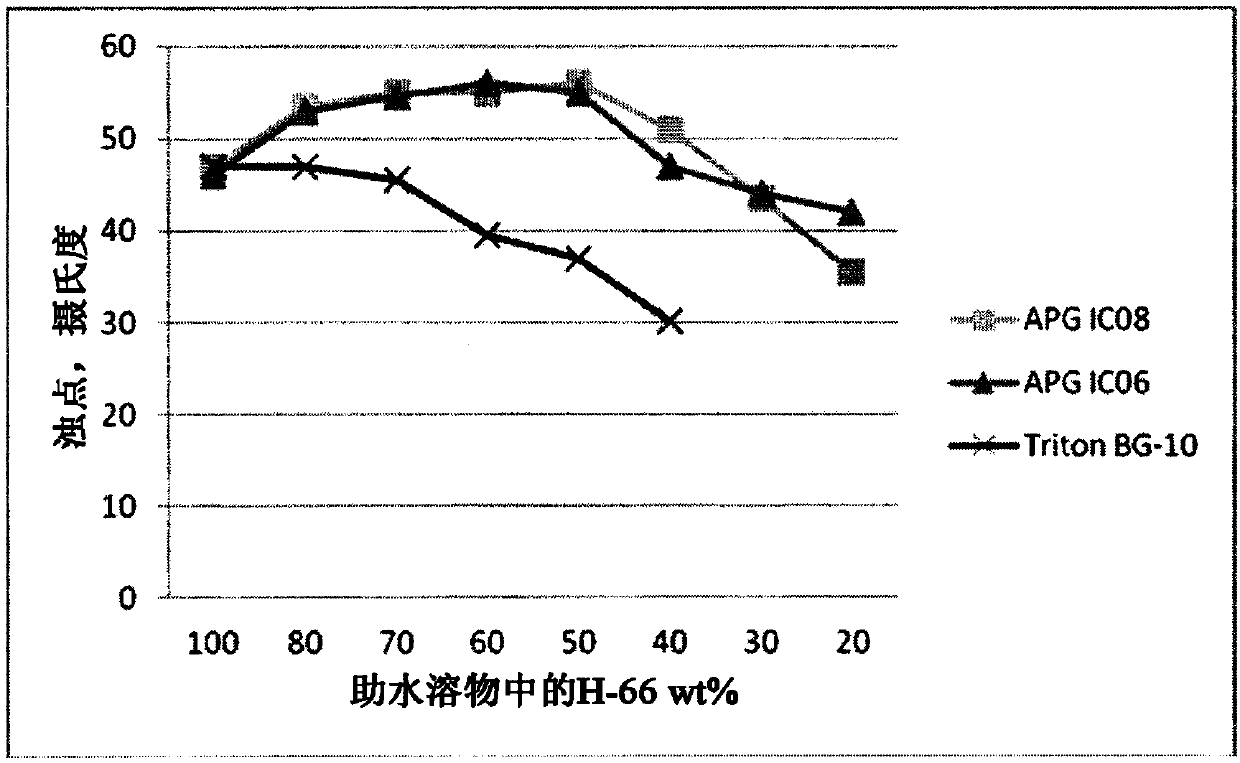

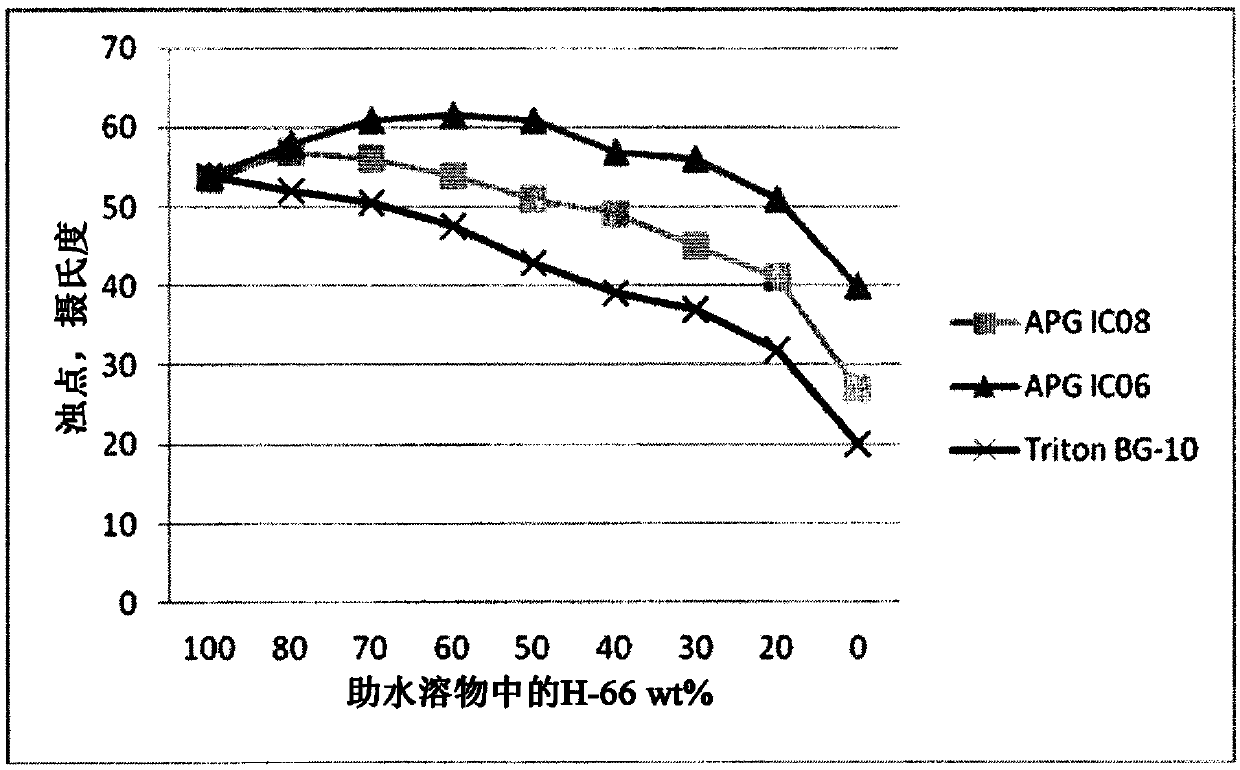

[0032] The cloud point temperature of each sample in Table 1 was determined according to the following cloud point temperature characterization procedure:

[0033] cloud point temperature

[0034] 10 ml of the sample solution was introduced into a transparent glass tube having a diameter of 15 mm and a len...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com