Vegetable drying process line

An assembly line and drying technology, applied in the direction of dehydration preservation of fruits/vegetables, etc., can solve the problems of low efficiency and difficulty in guaranteeing processing quality, and achieve the effects of wide adaptability, high production efficiency, and inhibition of enzymatic oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

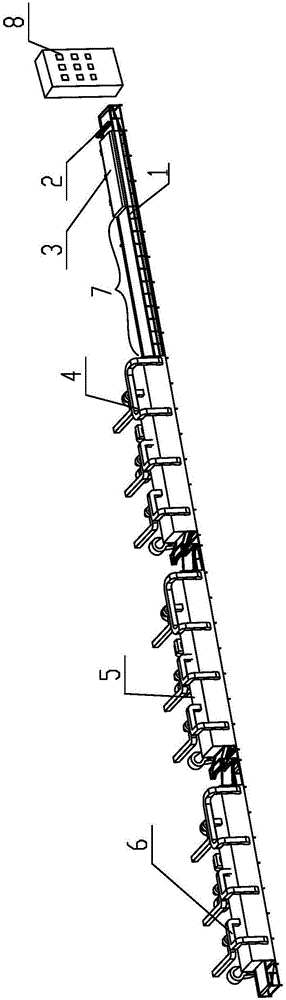

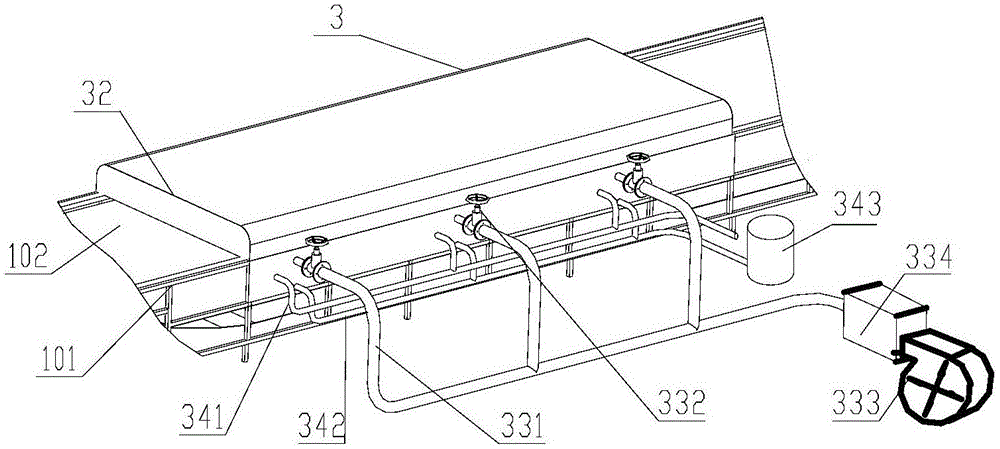

[0056] see figure 1 , the vegetable drying and processing line in the illustration is a preferred embodiment of the present invention, specifically including a material conveying system 1, a material feeding and sorting device 2, a greening device 3, a primary drying device 4, a secondary drying device 5, and a three-stage drying device. The drying device 6, the cooling section 7 and the control system, wherein the material feeding and sorting system 2, the greening device 3, the cooling section 7, the primary drying device 4, the secondary drying device 5 and the tertiary drying device 6 follow the material successively The conveying direction is arranged on the material conveying system 1.

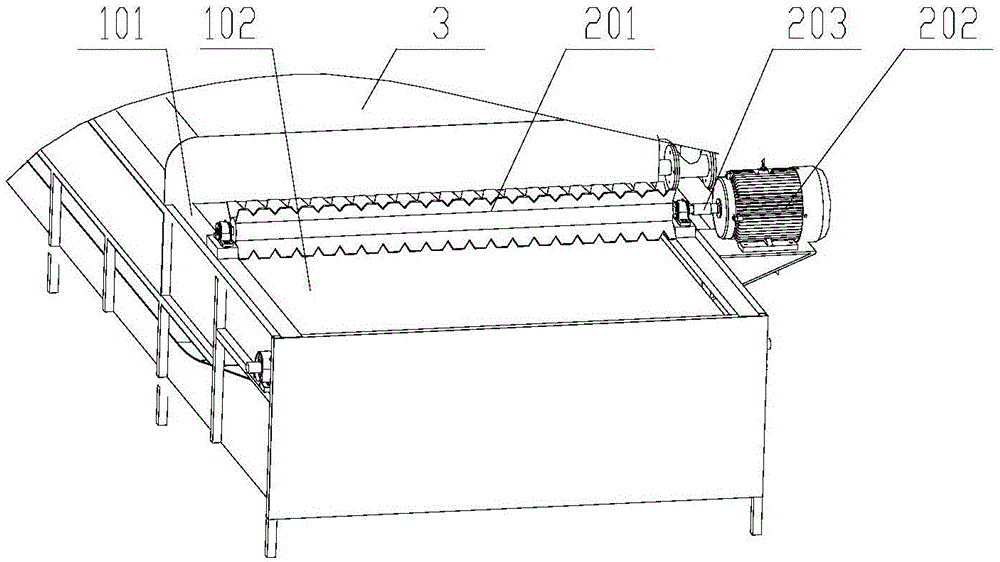

[0057] specific as figure 2 As shown, the feeding and sorting device 2 in this embodiment includes a toothed rake roller 201 horizontally arranged at the feeding end of the conveyor belt. The toothed rake roller 201 is installed above the conveyor belt of the material conveying system ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com