Dehydrated daylily production method

A production method and technology for daylily, applied in food science and other directions, can solve the problems of changing the natural color and luster of daylily, difficult for consumers to identify the quality, affecting the appearance and the quality of diet therapy, and achieving good dehydration effect, bright and natural color, and long shelf life. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

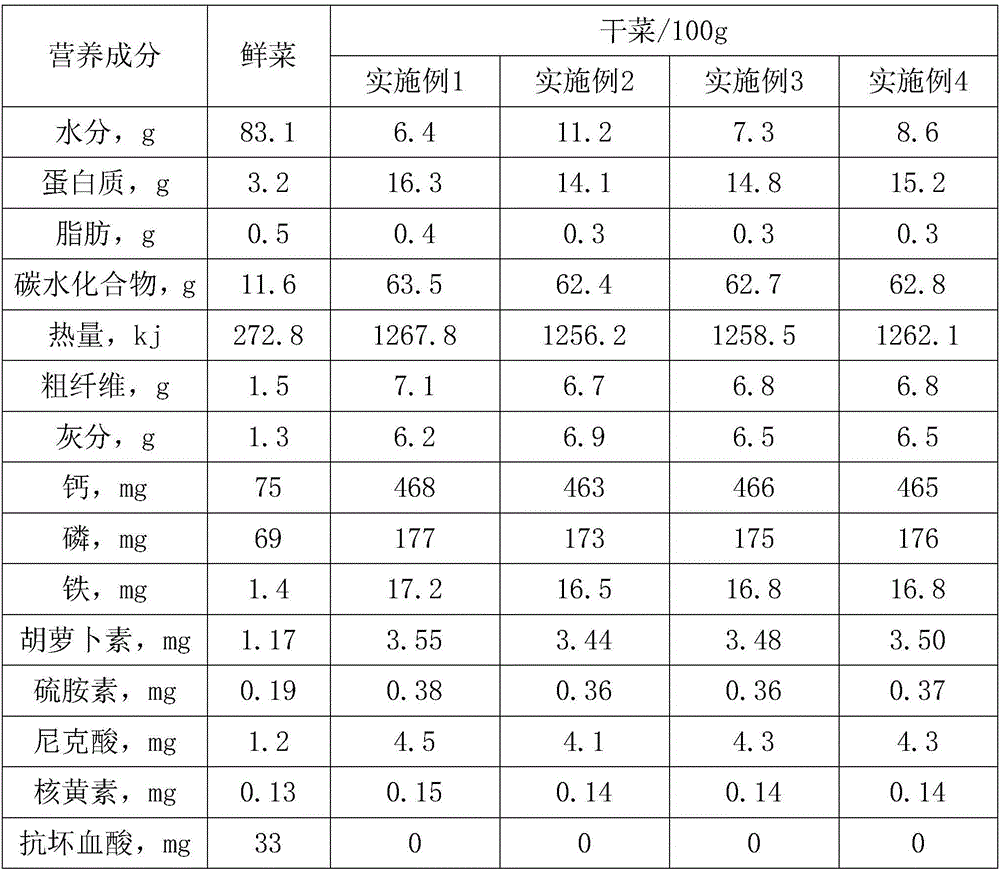

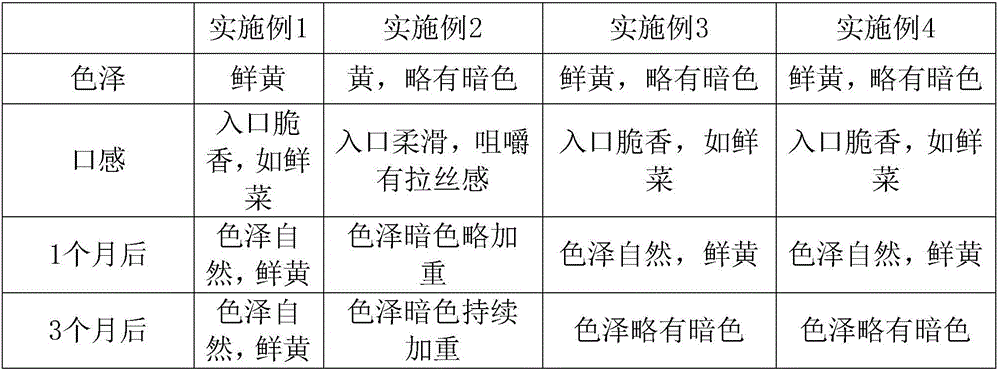

Examples

Embodiment 1

[0020] A method for producing dehydrated day lily, comprising the following steps:

[0021] 1) Harvesting and pretreatment: From 6:00 am to 8:00 pm or from 17:00 pm to 19:00 pm, pick the yellow leaves with full, uniform and complete strips, broken bars, broken heads, flowering vegetables ≤ 3%, and bar length > 9cm. For green day lily, remove the old stems, put it in a citric acid solution at 80-90°C, blanch it for 30-40 seconds, take it out while it is hot, and freeze it at ~8°C for 10-12 minutes, then turn it into The temperature is 0-10°C, the relative humidity of the air is 20-30%, the oxygen content is less than 2%, the carbon dioxide content is 80-90%, and the nitrogen content is 18-8%, and the anaerobic storage is stored for 30-60 minutes. The mass concentration of the citric acid solution is 0.05% to 0.10%;

[0022] 2) Plate loading: evenly spread the daylily stored in step 1) on the plate evenly, and the thickness of the material layer is controlled between 350-400mm;...

Embodiment 2

[0027] A method for producing dehydrated day lily, comprising the following steps:

[0028] 1) Harvesting and pretreatment: From 6:00 am to 8:00 pm or from 17:00 pm to 19:00 pm, pick the yellow leaves with full, uniform and complete strips, broken bars, broken heads, flowering vegetables ≤ 3%, and bar length > 9cm. For green day lily, remove the old stems, put it in a citric acid solution at 80-90°C, blanch it for 30-40 seconds, take it out while it is hot, and freeze it at ~8°C for 10-12 minutes, then turn it into The temperature is 0-10°C, the relative humidity of the air is 20-30%, the oxygen content is less than 2%, the carbon dioxide content is 80-90%, and the nitrogen content is 18-8%, and the anaerobic storage is stored for 30-60 minutes. The mass concentration of the citric acid solution is 0.05% to 0.10%;

[0029] 2) Put the day lily pretreated in step) 1 into a tray, put it into a normal steam room, and steam it at 85°C for 5 minutes, take it out and spread it out t...

Embodiment 3

[0032] A method for producing dehydrated day lily, comprising the following steps:

[0033] 1) Harvesting and pretreatment: From 6:00 am to 8:00 pm or from 17:00 pm to 19:00 pm, pick the yellow leaves with full, uniform and complete strips, broken bars, broken heads, flowering vegetables ≤ 3%, and bar length > 9cm. green day lily, old stems removed;

[0034] 2) Plate loading: evenly spread the daylily stored in step 1) on the plate evenly, and the thickness of the material layer is controlled between 350-400mm;

[0035]3) Build a steam room: set up a conveyor belt in the steam room, and set the speed of the conveyor belt to 0.14-0.16m / min; The steam room is marked as room 1, room 2, room 3 and room 4 from left to right;

[0036] 4) Dehydration and inactivation of enzymes: Place the tray installed in step 2) on the conveyor belt in step 3, turn on the power supply of the conveyor belt, and make the tray slowly pass through chamber 1, chamber 2, chamber 3 and chamber 1 from le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com