A kind of biological fermentation feed production equipment and production method

A technology for biological fermentation feed and production equipment, which is applied in the field of biological fermentation feed production equipment, can solve the problems of difficult production process control, many manual operation links, and great damage to product quality, so as to avoid quality damage, avoid temperature rise, and improve fermentation quality. stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] In order to make the purpose, technical solutions and advantages of the present invention clearer, the technical solutions of the exemplary embodiments of the present invention will be further described below.

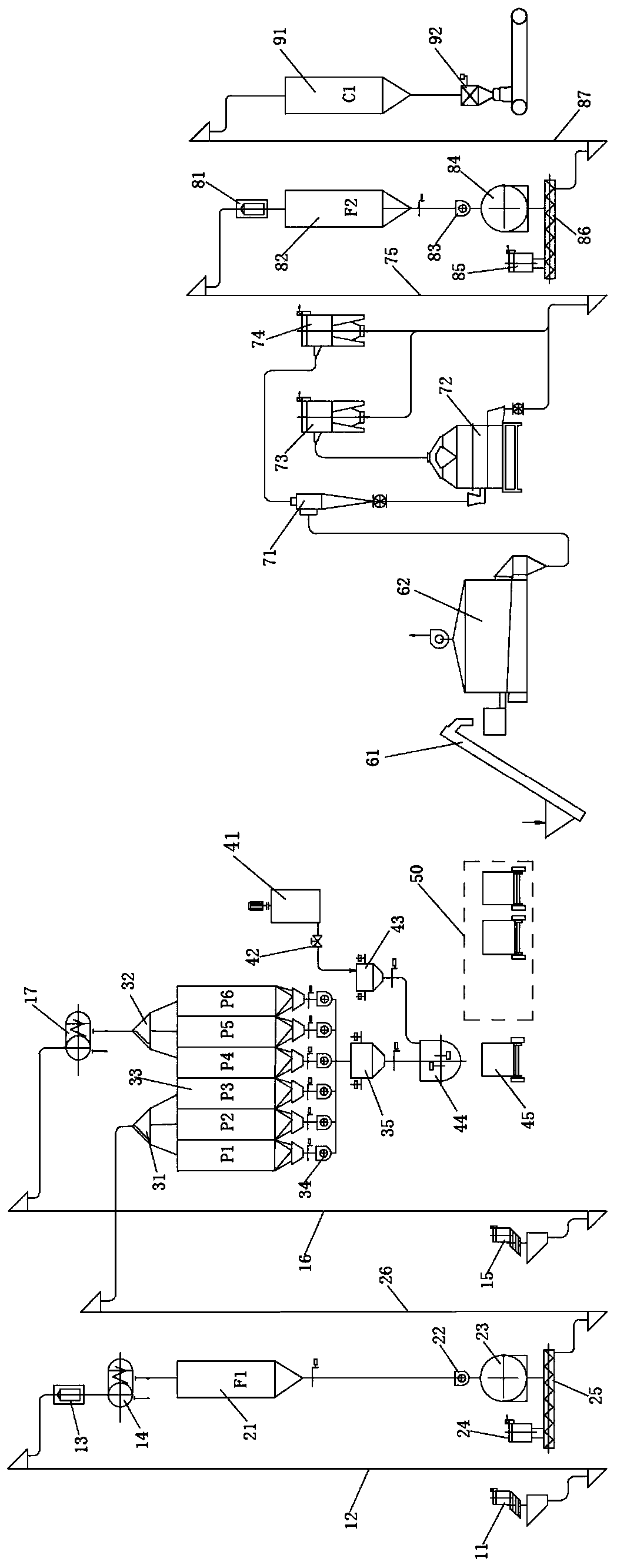

[0040] The invention provides a kind of biological fermentation feed production equipment, according to the processing flow of fermentation raw materials, including the first cleaning section, the raw material crushing section, the batching section, the bacteria liquid adding and mixing section, the constant temperature fermentation section, the low temperature drying section, the cooling Section, finished product crushing section and finished product packaging section, wherein the batching section is also connected with the second cleaning section.

[0041] According to the different sources of fermentation raw materials, the production equipment of the present invention can be applied to a variety of raw materials. If pulverization is required, the raw material...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com