Combined production system and method of polyvinyl chloride resin

A polyvinyl chloride resin and joint production technology, which is applied in ethylene production, biological raw materials, chemical recycling, etc., can solve the problems of large environmental pollution and high production costs, and achieve the effect of reducing investment, reducing corrosion, and realizing comprehensive recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

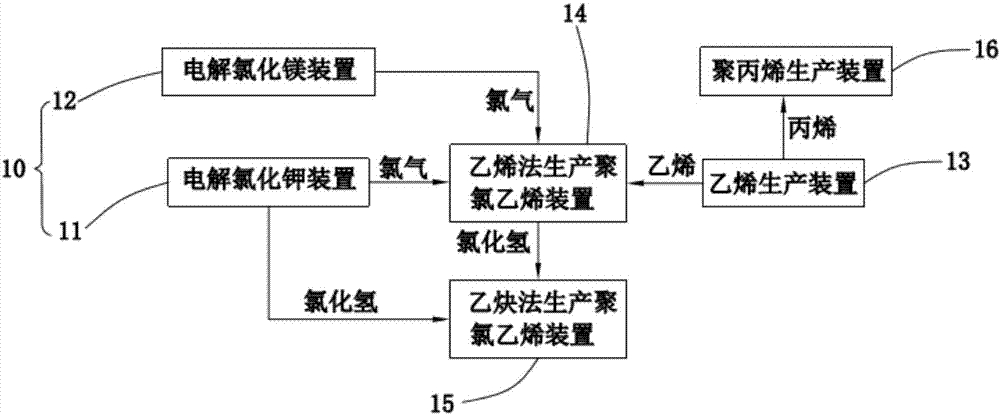

[0081] Such as figure 1 As shown, the present embodiment provides a joint production system of polyvinyl chloride resin, which includes a chlorine gas generating device 10, an ethylene production device 13, an ethylene method for producing polyvinyl chloride device 14, an acetylene method for producing polyvinyl chloride device 15, a polypropylene Production device 16.

[0082] Described chlorine generating device 10 comprises electrolytic potassium chloride device 11 and electrolytic magnesium chloride device 12; Connection; said electrolytic magnesium chloride device 12 is connected with said ethylene method production of PVC device 14.

[0083] The ethylene production unit 13 , the ethylene-based PVC production unit 14 , and the acetylene-based PVC production unit 15 are sequentially connected, and the ethylene production unit 13 is also connected to the polypropylene production unit 16 .

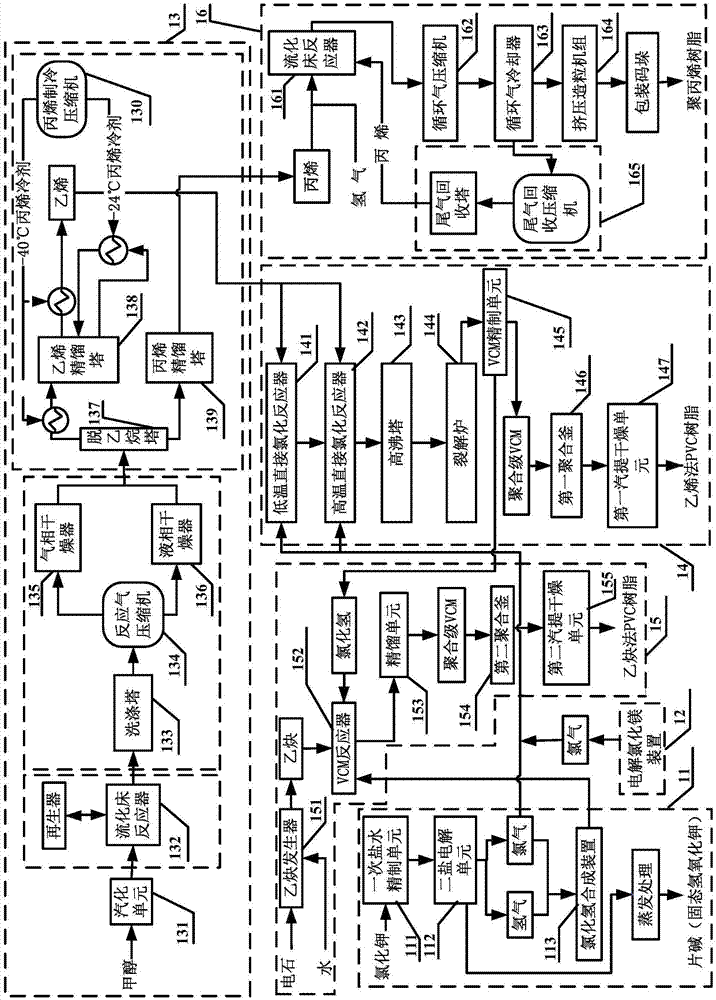

[0084] Such as figure 2 Shown, the joint production method of described polyviny...

Embodiment 2

[0131] PVC resin was prepared according to the steps in Example 1, but chlorine was only provided by the electrolytic potassium chloride device 11.

Embodiment 3

[0133] The PVC resin is prepared according to the steps in Example 1, but the production scale of the production of PVC device 15 by the acetylene method is determined according to the scale of the hydrogen chloride produced by the PVC device 14 by the ethylene method, that is, the production of the PVC device 15 by the acetylene method The raw material hydrogen chloride is only provided by the polyvinyl chloride production unit 14 by the ethylene method.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com