Processing technology of aluminum alloy workpiece and full-automatic binding machine

A processing technology, a nailing machine technology, applied in the direction of metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of workpiece fine hole pollution or blockage, difficult to clean, difficult operation, etc., to achieve high nailing efficiency, Simple structure, stable process action and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

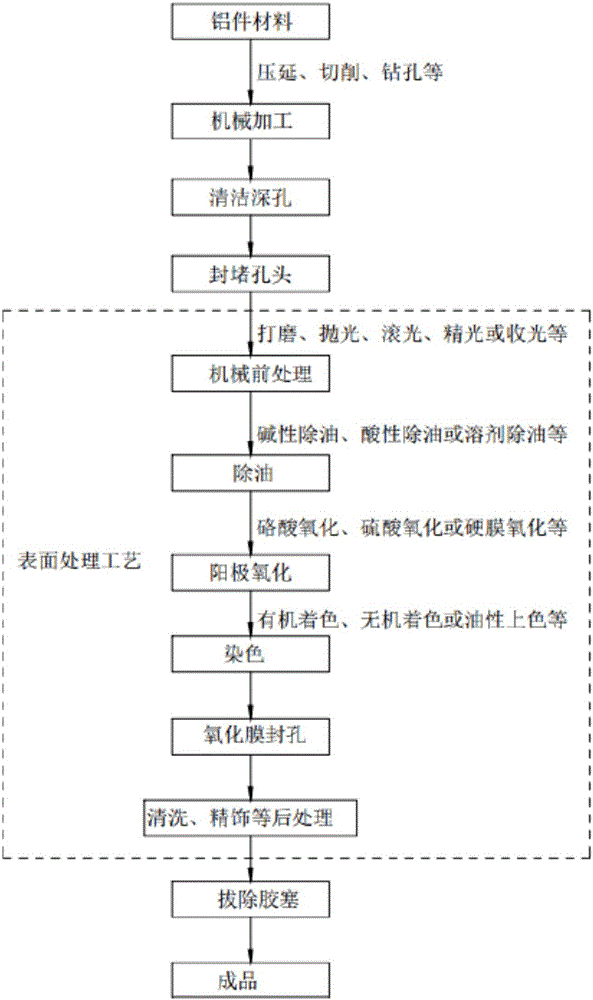

[0045] A processing technology for an aluminum alloy workpiece, Figures 1 to 7 shown, including the following steps,

[0046] The machining step is to perform at least one processing step of rolling, stamping, cutting or milling and drilling on the workpiece made of aluminum or aluminum alloy material to obtain a semi-finished workpiece with workpiece pores 10;

[0047] The fine hole cleaning step is to place the semi-finished workpiece in the positioning fixture, insert a cleaning needle 6 with at least one water spray hole 61 on the top surface and / or side of the head into the fine hole 10 of the workpiece, and pass the cleaning needle 6 The water spray hole 61 sprays a high-pressure water column into the workpiece pore 10, and the high-pressure water column forms a high-speed and high-pressure eddy current in the workpiece pore 10, and the workpiece pore 10 is cleaned;

[0048] Drying step, drying or drying the workpiece pores 10 of the semi-finished workpiece,

[0049] ...

Embodiment 2

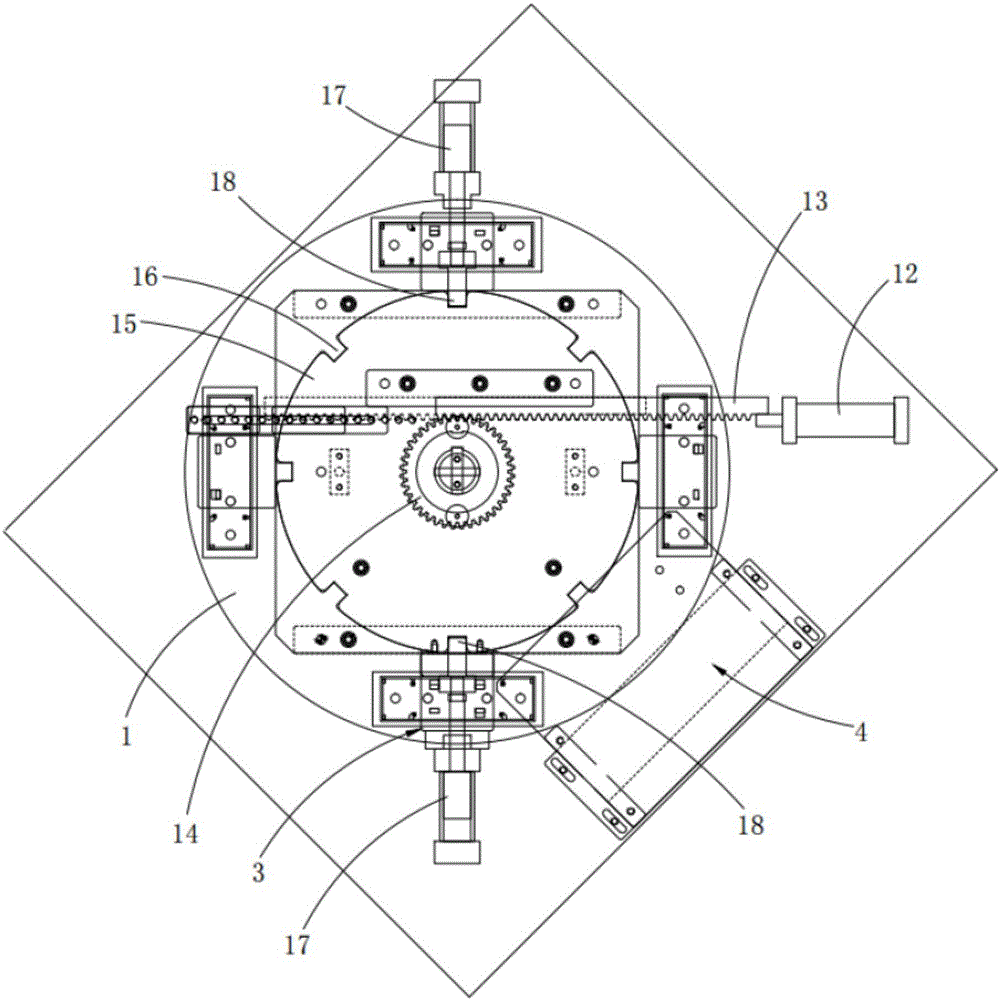

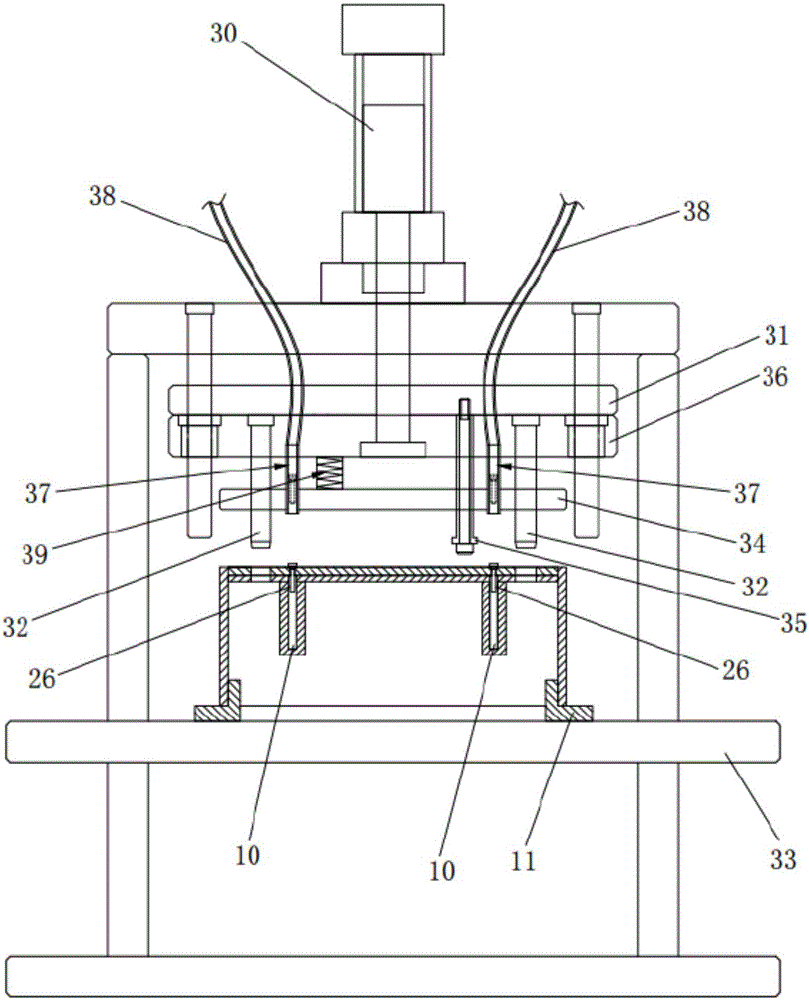

[0059] Fully automatic stapler, see Figure 2 to Figure 7 As shown, it includes frame, turntable 1, indexing drive mechanism, rubber nail positioning fixture 2, glue blowing nail mechanism 3 and glue nail mechanism 4, turntable 1 is rotatably installed on the upper part of the frame, and index drive mechanism is installed On the upper part of the frame, the indexing drive mechanism is connected to the turntable 1, and the indexing drive mechanism is used to drive the turntable 1 to intermittently rotate the set angle a, and the turntable 1 is provided with a number of workpiece positioning fixtures 11 for positioning the workpiece at intervals; the glue blowing nail mechanism 3 and the glue nail mechanism 4 are respectively installed on the upper part of the frame, and the blow glue nail mechanism 3 and the glue nail mechanism 4 are respectively arranged at the side positions of the turntable 1.

[0060] The indexing drive mechanism includes a hydraulic cylinder 12, a straight...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com