Non-API thread ring gauge electroplating super-hard abrasive molded grinding wheel matrix structure design method

A thread ring gauge and forming grinding wheel technology, applied in grinding/polishing equipment, grinding equipment, metal processing equipment, etc., can solve the problems of non-API thread ring gauge grinding burns, efficient material removal, etc. The effect of improving material removal rate, improving grinding efficiency, and avoiding parts grinding burns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific method of the present invention will be further described below in conjunction with a processing example of a non-API threaded ring gauge of a certain specification.

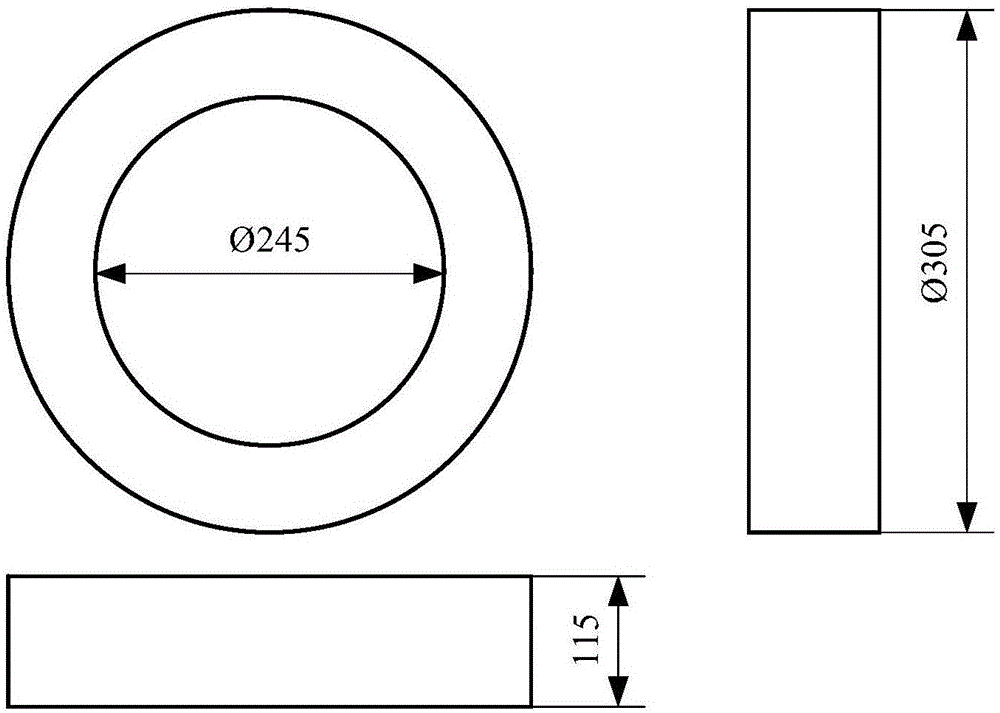

[0026] see figure 1 Schematic of non-API threaded ring gauge stock shown. The material is 9Mn2V. After spheroidizing annealing, the blank is turned into a torus, and then quenched + shallow cooling + tempering + shallow cooling + tempering + aging heat treatment. The blank size is Ø305mm×Ø245mm×115mm.

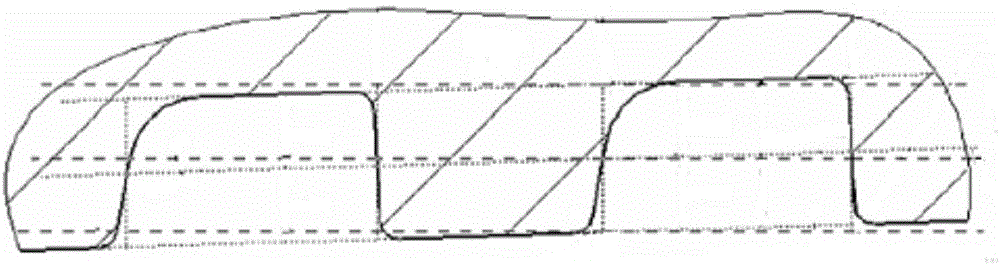

[0027] see figure 2 Schematic diagram of the non-API threaded ring gauge thread construction shown. The internal thread taper of the part is 1°47´24, the pitch is 5.08mm, and the tooth depth is 1.575mm. The processing quality requirements of finished parts are: the thread tooth depth tolerance is 0.013mm, the tooth width tolerance is 0.025mm; the transition fillet dimensions of the thread guide surface and the bearing surface are R0.203mm and R0.762mm respectively, and the transition fille...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com