Production line of frame-carried precast slab

A production line and prefabricated panel technology, applied in manufacturing tools, ceramic molding workshops, auxiliary molding equipment, etc., can solve the problems of difficult control of material consumption, high labor intensity, and low production efficiency, so as to maintain quality stability and reduce labor Strength and the effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with accompanying drawing, describe the best implementation mode of the present invention through preferred embodiment, the specific implementation mode here is to illustrate the present invention in detail, and should not be interpreted as the limitation of the present invention, without departing from the spirit and essence of the present invention Various changes and modifications can be made within the scope of the present invention, and these should be included in the protection scope of the present invention.

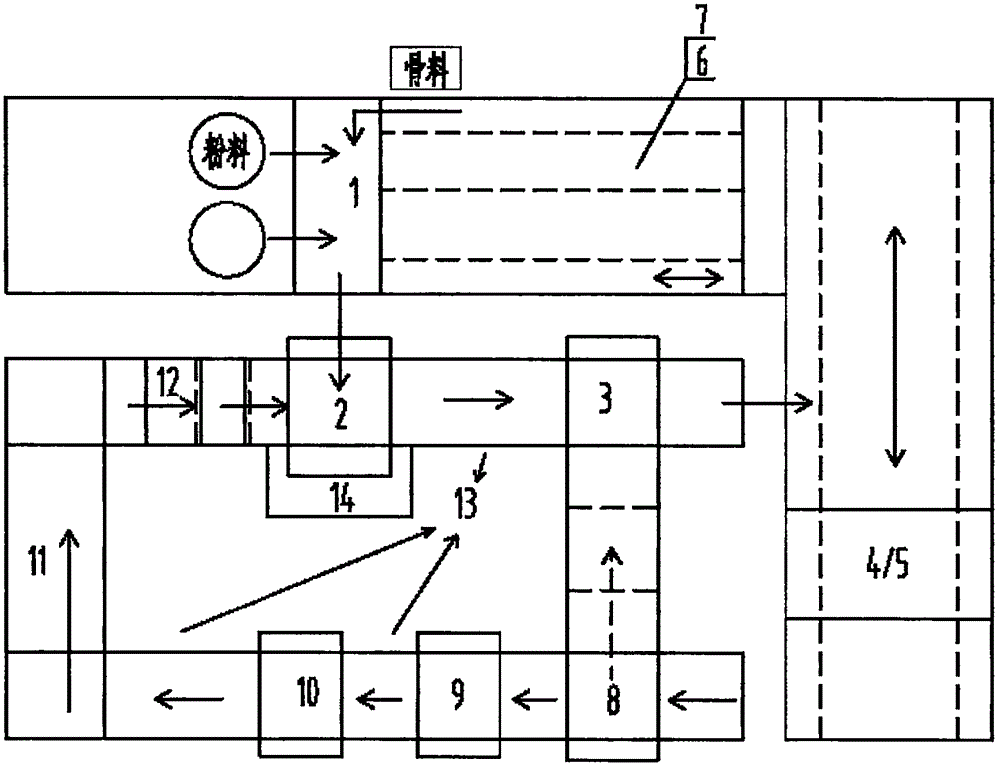

[0027] see Figure 1-2 , the invention provides a production line of framed prefabricated panels. The production line of framed prefabricated panels can include:

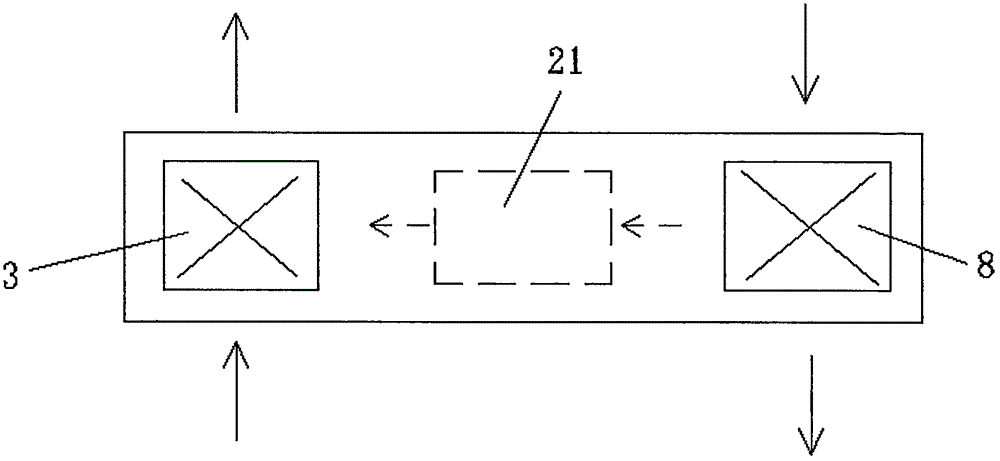

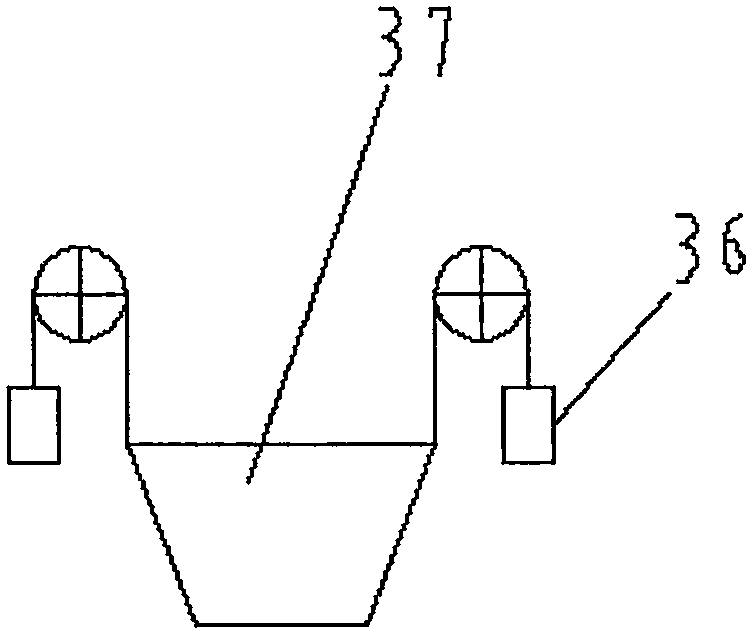

[0028] The main circuit consists of a material distribution system 2, a stacking system 3, a maintenance system, a plate removal system 8, a demoulding and palletizing system 9, a mold frame placement system 10, a mold frame lateral movement system 11, and a push plate mecha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com