A plastic fiberboard laminating machine

A board lamination machine and plastic fiber technology, which is applied in the field of lamination machines, can solve the problems of low production efficiency and large labor consumption, and achieve the effects of reducing quality costs, saving labor costs, and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The concept, specific structure and specific effects of the present invention will be clearly and completely described below in conjunction with the embodiments and drawings, so as to fully understand the purpose, features and effects of the present invention. The various technical features created by the present invention can be combined interactively on the premise of not contradicting each other.

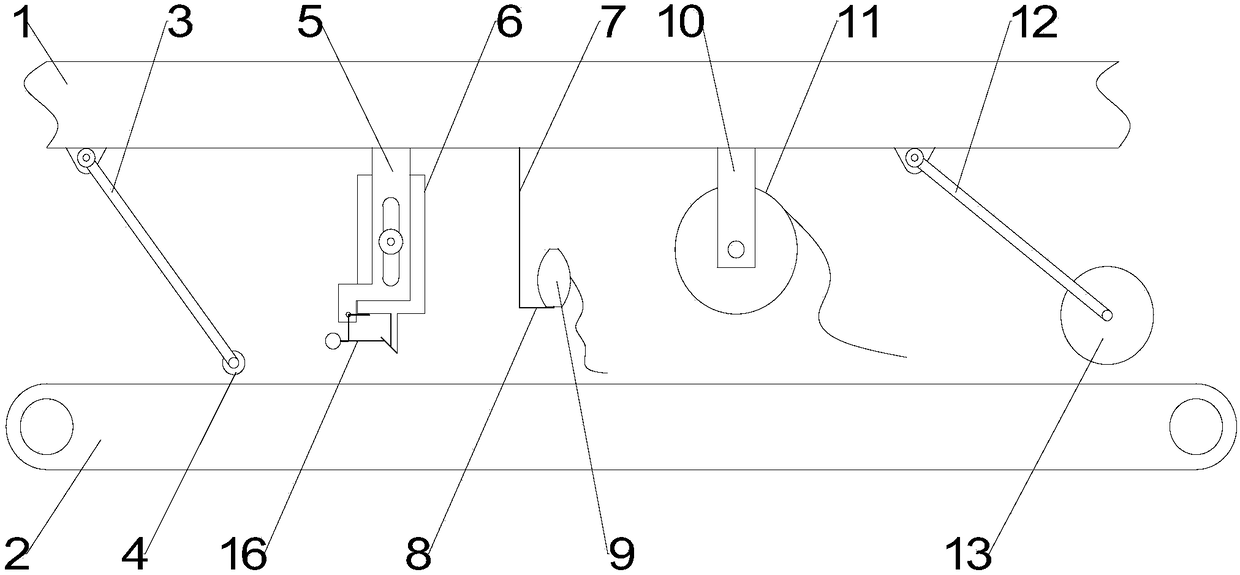

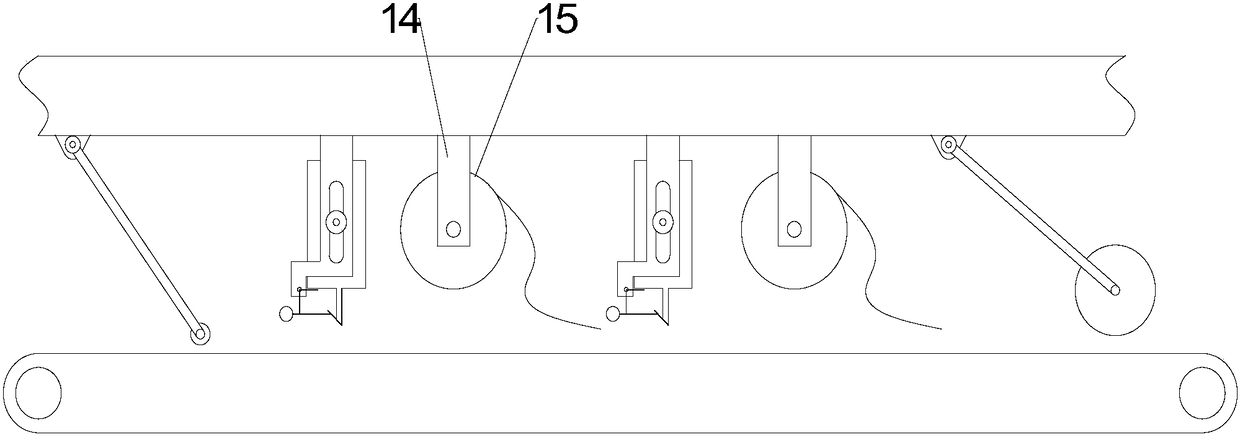

[0029] see figure 1 , a plastic fiberboard laminating machine, characterized in that it includes an execution unit, a power unit and a control unit;

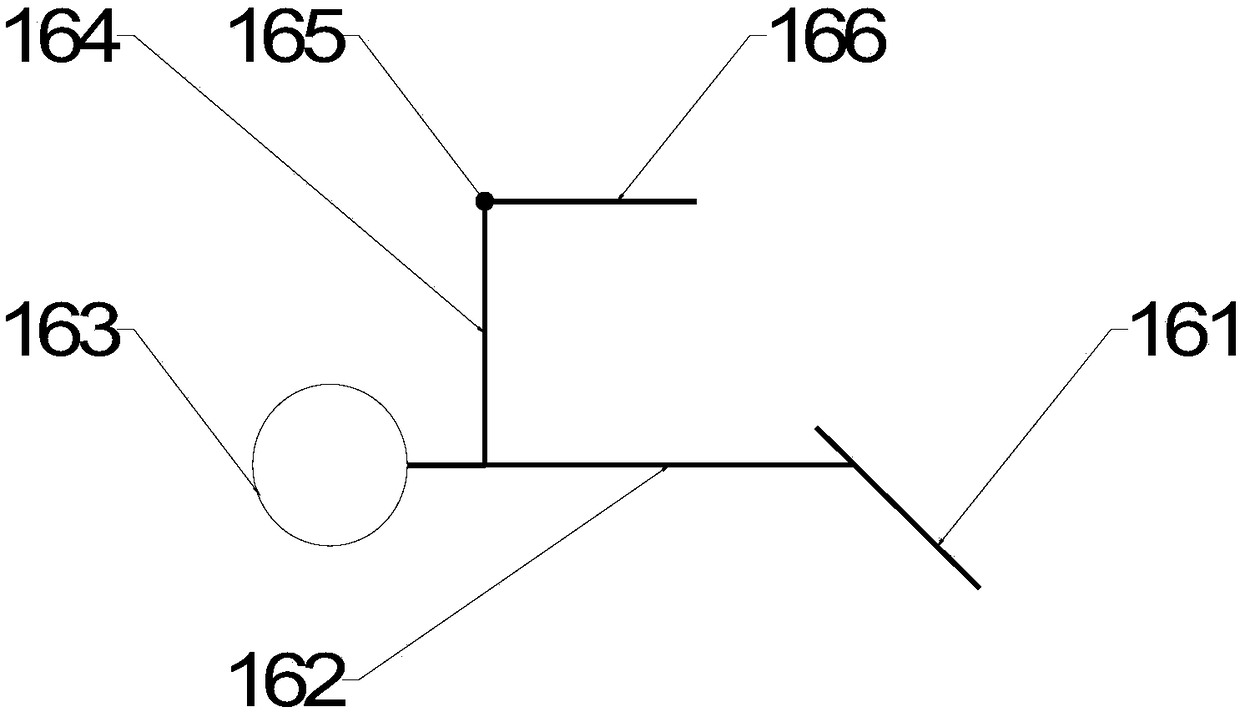

[0030] The execution unit includes a body 1, a conveyor belt 2, a preheating module, a glue coating module, a fiber adding module, a plastic laminate module and a pressing module; the conveyor belt 2 is located inside the body 1, and the conveyor belt 2 is pressed The conveying direction of the conveyor belt 2 is provided with the preheating module, the gluing module, the fiber adding module, the plastic laminate module and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com