Desliming agent for slime-bearing sylvinite and processing method for slime-bearing sylvinite

A processing method and a technology for potassium rock salt, which are applied in the field of mud-containing potassium rock salt desliming agent and mud-containing potassium rock salt processing field, can solve the problems of unsatisfactory desliming effect, etc. The effect of reducing the processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

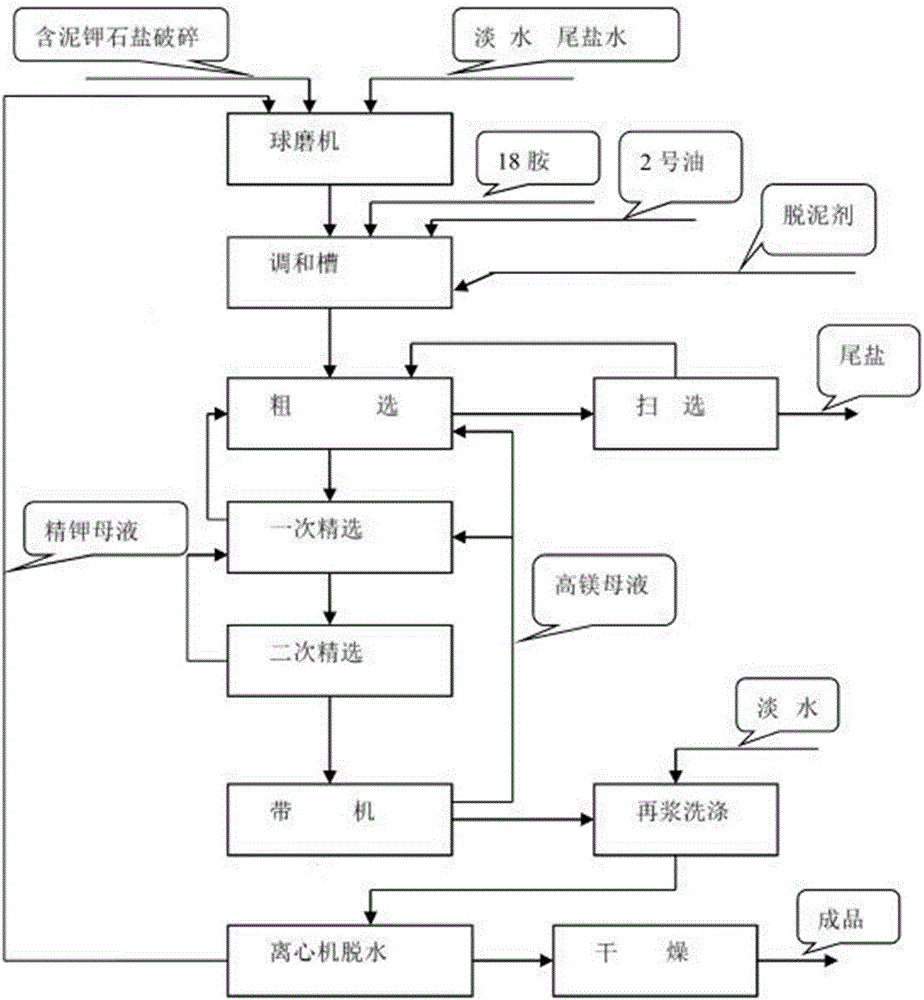

Image

Examples

Embodiment 1

[0023] A method for processing clay-containing potassium halite, comprising the steps of:

[0024] (1) Grinding the crushed mud-containing potassium halite through a ball mill, mixing the ore particles and a solvent to form a slurry with a mass concentration of 65%, and the content of potassium salt ore with a particle size of ≤0.15mm after grinding accounts for 70%; The raw ore grade (calculated by KCl) of the mud-containing potassium halite is 19.1%, and the mud-containing rate of the raw ore is 10.9%;

[0025] (2) Send the material obtained in step (1) into the blending tank, add desliming agent carboxymethyl cellulose, collector octadecyl primary amine, and foaming agent No. 2 oil successively and stir to make it fully mixed Wherein the degree of etherification of carboxymethyl cellulose is 0.78, and the addition amount is 40g per ton of raw ore; when in use, carboxymethyl cellulose is formulated into an aqueous solution with a mass fraction of 2%;

[0026] (3) carry out ...

Embodiment 2

[0030] A method for processing clay-containing potassium halite, comprising the steps of:

[0031] (1) Grinding the crushed mud-containing potassium halite through a ball mill, mixing the ore particles and a solvent to form a slurry with a mass concentration of 70%, and the content of potassium salt ore with a particle size of ≤0.15mm after grinding accounts for 70%; The raw ore grade (calculated by KCl) of the mud-containing potassium halite is 19.1%, and the mud-containing rate of the raw ore is 10.9%;

[0032] (2) Send the material obtained in step (1) into the blending tank, add desliming agent carboxymethyl cellulose, collector octadecyl primary amine, and foaming agent No. 2 oil successively and stir to make it fully mixed Wherein the degree of etherification of carboxymethyl cellulose is 0.85, and the addition amount is 30g per ton of raw ore; when in use, carboxymethyl cellulose is prepared into an aqueous solution with a mass fraction of 3%;

[0033] (3) carry out fl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Etherification degree | aaaaa | aaaaa |

| Etherification degree | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com