Modified asphalt and preparation method and application thereof

A technology of modified asphalt and asphalt, which is applied in the field of modified asphalt and its preparation, which can solve the problems of road surface damage, weakened road performance of modified asphalt, and low bond energy, and achieve improved production efficiency, excellent stability, and stable quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

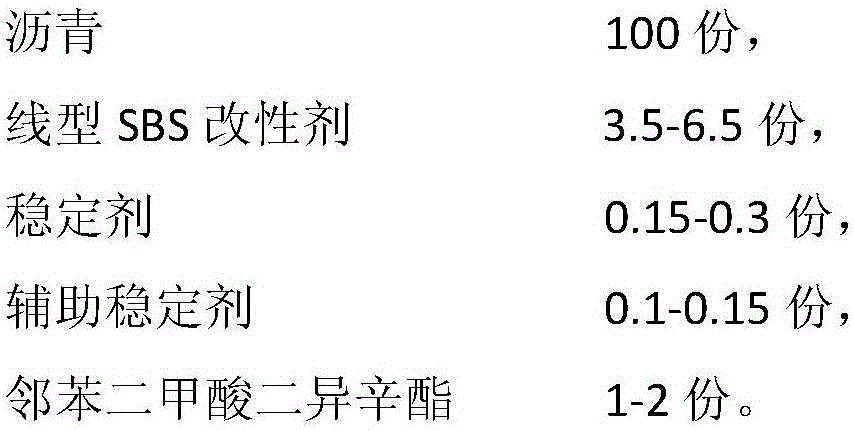

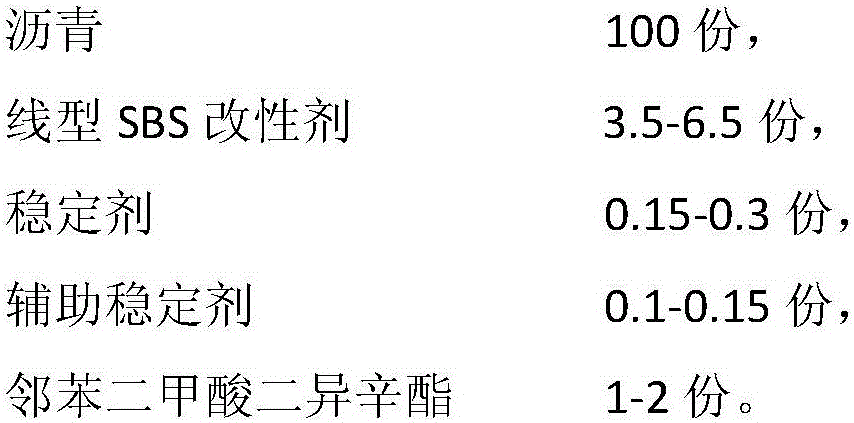

[0065]

[0066] A kind of preparation method of modified asphalt, it comprises the following steps:

[0067] (1), mix asphalt and linear SBS modifier, shear, obtain the first mixture;

[0068] (2), adding stabilizer and auxiliary stabilizer to the first mixture and stirring to obtain the second mixture;

[0069] (3) After the linear SBS modifier swells and develops, add di-isooctyl phthalate into the second mixture, and stir to obtain modified asphalt.

[0070] Wherein, in step (1), the shearing temperature can be 200-220°C, preferably 210°C, the shearing speed can be 1500-1800 rpm, preferably 1800 rpm, and the shearing time can be 3-5h, preferably 4h.

[0071] In step (2), the stirring temperature can be 180-220°C, preferably 180°C, and the stirring time can be 1-2h, preferably 2h.

[0072] In step (3), the stirring time can be 1-2h, preferably 2h.

[0073]

[0074] A modified asphalt prepared by the above preparation method can be applied in road surface.

Embodiment

[0077] The preparation method of the modified asphalt of the present embodiment, it may further comprise the steps:

[0078] (1) Mix 100 parts of No. 70 petroleum asphalt with 4 parts of linear SBS modifier, shear, the temperature is 210 ° C, the speed is 1800 rpm, and the time is 4 hours to obtain the first mixture;

[0079] (2) Add 0.15 parts of sulfur and 0.15 parts of inorganic phosphoric acid into the first mixture and stir at a temperature of 180° C. for 2 hours to obtain a second mixture;

[0080] (3) After the linear SBS modifier swells and develops, add 1 part of di-isooctyl phthalate to the second mixture, and stir for 2 hours to obtain modified asphalt.

[0081] Among them, the asphalt is No. 70 petroleum asphalt, with a saturated content of 8%, an aromatic content of 42%, a softening point of 46.3°C, and a penetration of 68 at 25°C.

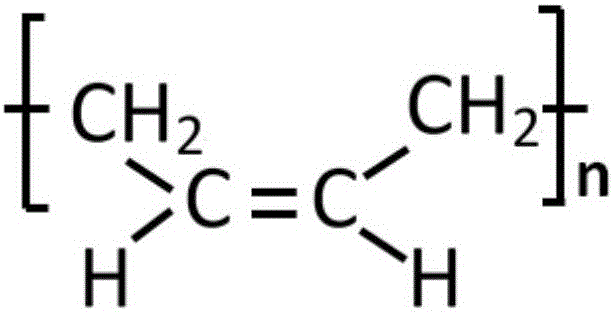

[0082] The molecular weight of the linear SBS modifier is 60,000, the block ratio of polystyrene and polybutadiene is 3:7, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com