Method for analyzing alpha-fluoromethyl acrylate and related substances

A technology for methyl fluoroacrylate and related substances, which is applied in the field of analysis of methyl α-fluoroacrylate and related substances, can solve problems that need to be improved, and achieve good elution and separation effects, strong accuracy, and significant sensitivity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

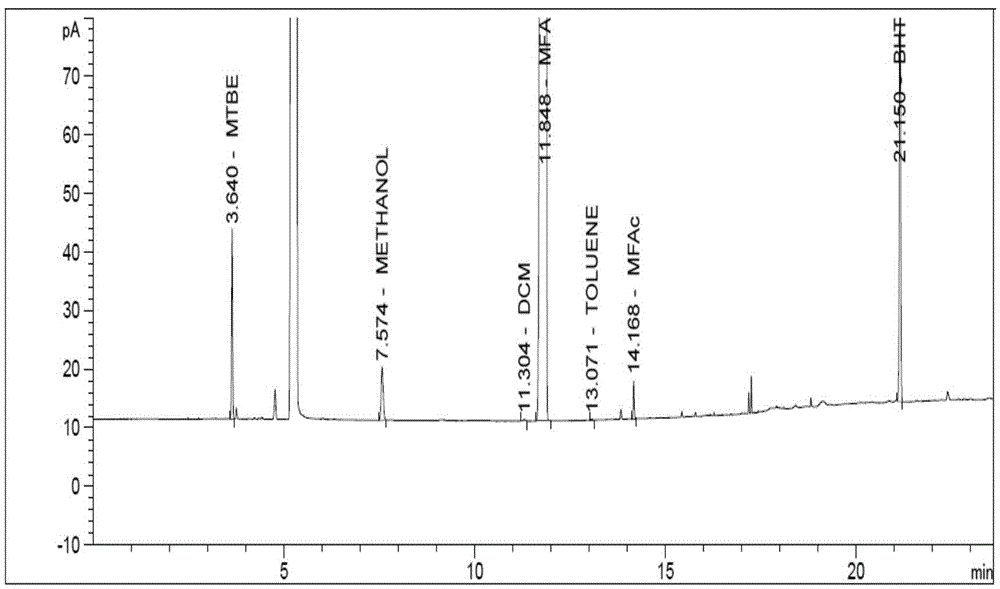

Embodiment 1

[0050] Instrument: Agilent7890A gas chromatograph, FID detector

[0051] Chromatographic column: DB-wax (30m×0.32mm×0.25μm);

[0052] The temperature programming conditions are:

[0053] Heating rate (℃ / min)

[0054] Flow rate: 1.0mL / min

[0055] Detector temperature: 250°C

[0056] Inlet temperature: 240°C

[0057] Injection volume: 1μL

[0058] Split ratio: 50:1

[0059] Diluent: Acetonitrile

[0060] Derivatization reagent: add 60mg trifluoroacetic acid to 2g acetonitrile

[0061] Running time: 23.6min

[0062] Experimental steps:

[0063] BHT reference substance stock solution: about 80mg of BHT reference substance, accurately weighed, put in a 50mL volumetric flask, add diluent to dissolve and dilute to the mark, and shake well.

[0064] Sample and each component reference substance solution: Weigh about 80mg of α-methyl fluoroacrylate reference substance, weigh about 40mg each of MeOH, Toluene, MtBE, DMC, MFAc reference substance, weigh them accurately...

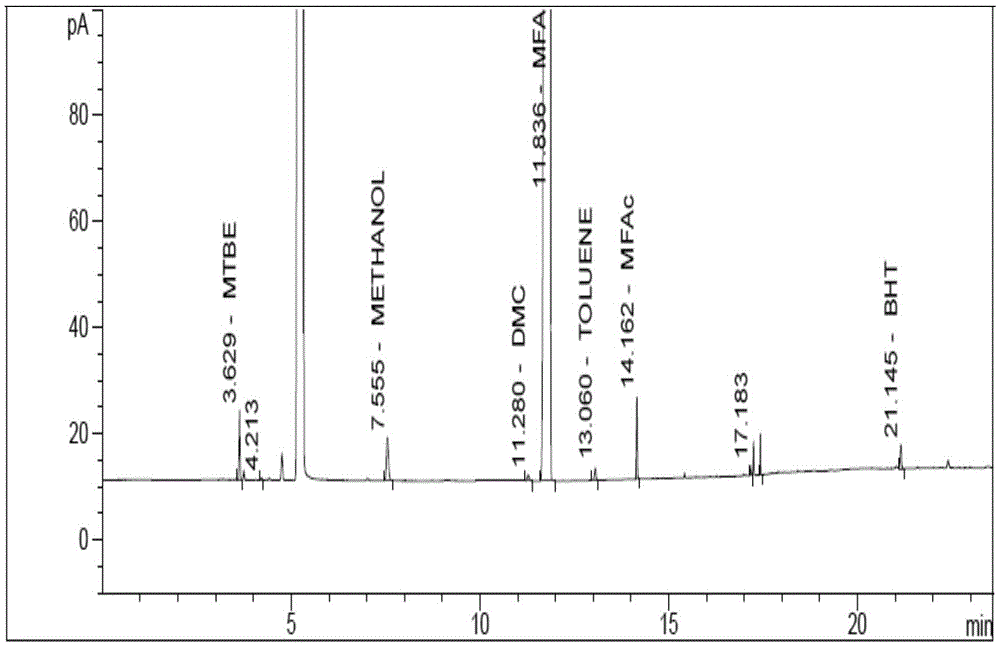

Embodiment 2

[0073] Instrument: Agilent7890A gas chromatograph, FID detector

[0074] Chromatographic column: DB-wax (30m×0.32mm×0.25μm);

[0075] The temperature programming conditions are:

[0076] Heating rate (℃ / min)

[0077] Flow rate: 1.0mL / min

[0078] Detector temperature: 250°C

[0079] Inlet temperature: 240°C

[0080] Injection volume: 1μL

[0081] Split ratio: 50:1

[0082] Diluent: Acetonitrile

[0083] Derivatization reagent: add 60mg trifluoroacetic acid to 2g acetonitrile

[0084] Runtime: 23.6 minutes

[0085] Experimental steps:

[0086] Impurity content reference substance solution: Take about 800mg of MFA reference substance, weigh it accurately, put it into a 10mL volumetric flask with 5mL diluent and 1mL derivatization reagent, add diluent to dissolve and dilute to the mark, shake well (80mg / mL ). Precisely pipette 1mL into a 200mL volumetric flask, add diluent to dilute to the mark, and shake well (0.4mg / mL).

[0087] Sample solution: Take about ...

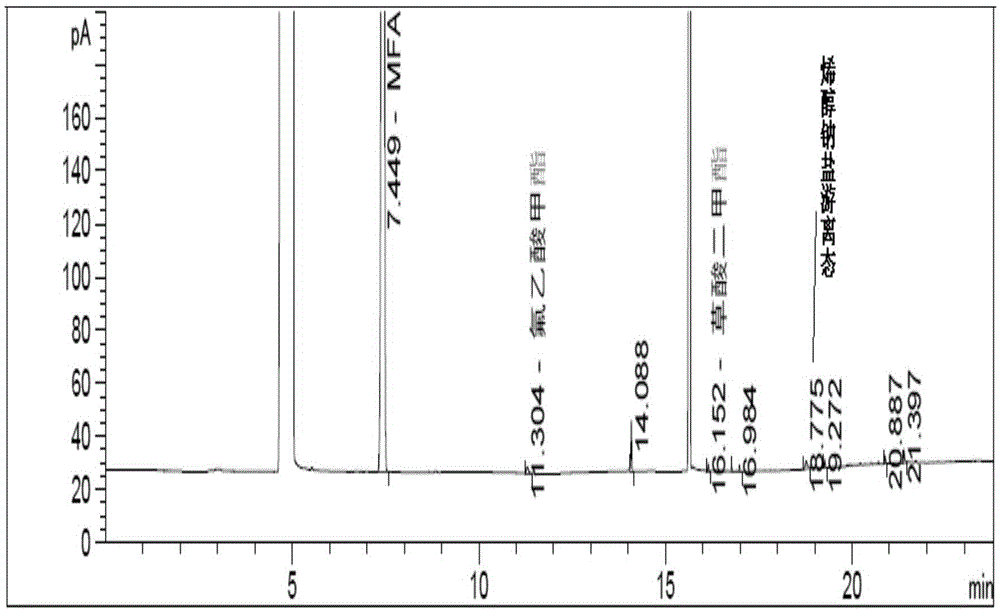

Embodiment 3

[0095] Instrument: Agilent7890A gas chromatograph, FID detector

[0096] Chromatographic column: DB-wax (30m×0.32mm×0.25μm);

[0097] The temperature programming conditions are:

[0098] Heating rate (℃ / min)

temperature(℃)

Hold time (min)

running time (min)

40

8

8

5

60

0

12

25

230

5

23.8

[0099] Flow rate: 1.0mL / min

[0100] Detector temperature: 250°C

[0101] Inlet temperature: 230°C

[0102] Injection volume: 1μL

[0103] Split ratio: 50:1

[0104] Thinner: Acetone

[0105] Derivatization reagent: add 100mg trifluoroacetic acid to 2g acetone

[0106] Running time: 23.8min

[0107] Experimental procedure: Accurately weigh about 200 mg of the MFA reaction solution, add 1 mL of derivatization reagent and 1 mL of diluent, shake well, and filter to obtain the product.

[0108] Conclusion: under this chromatographic condition, the gas chromatogram of gained α-fluoromethyl acrylate react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com