Directional growth regulation and control method of super-hydrophobic nano-structure organic film

An organic thin film and nanostructure technology, applied in metal material coating process, vacuum evaporation plating, coating and other directions, can solve the problems of high difficulty in realizing directional growth, low controllability of growth process, low interface adhesion, etc. Achieve significant practical value, improve hydrophobicity, and reduce secondary electron emission coefficients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The embodiments of the present invention will be further detailed below with reference to the accompanying drawings.

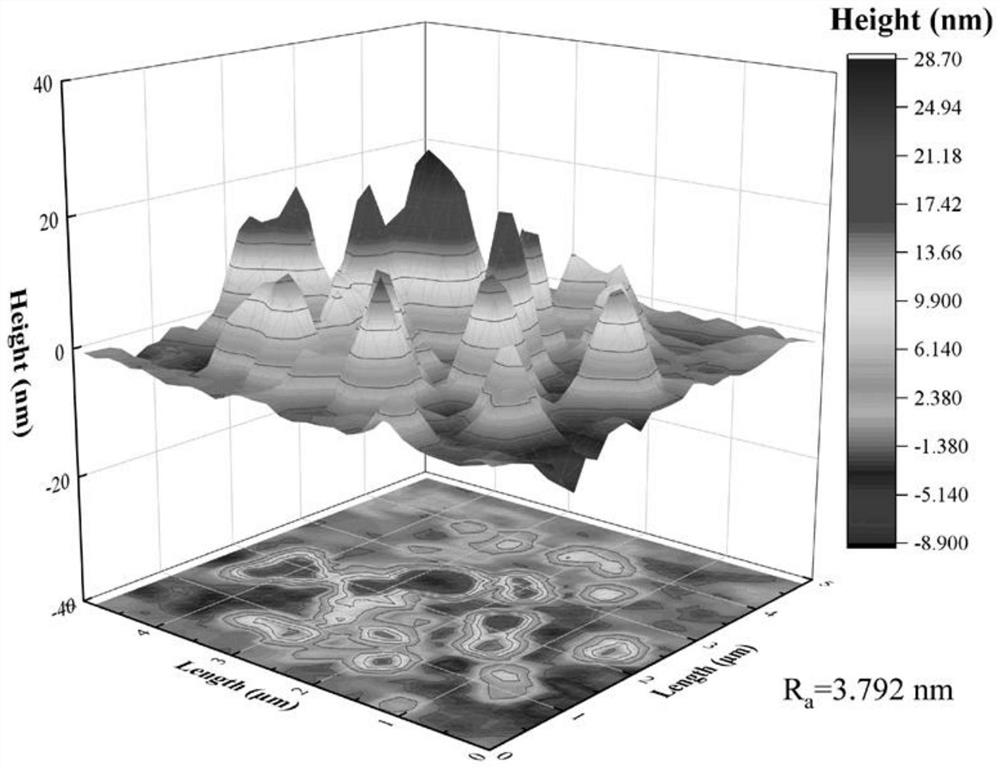

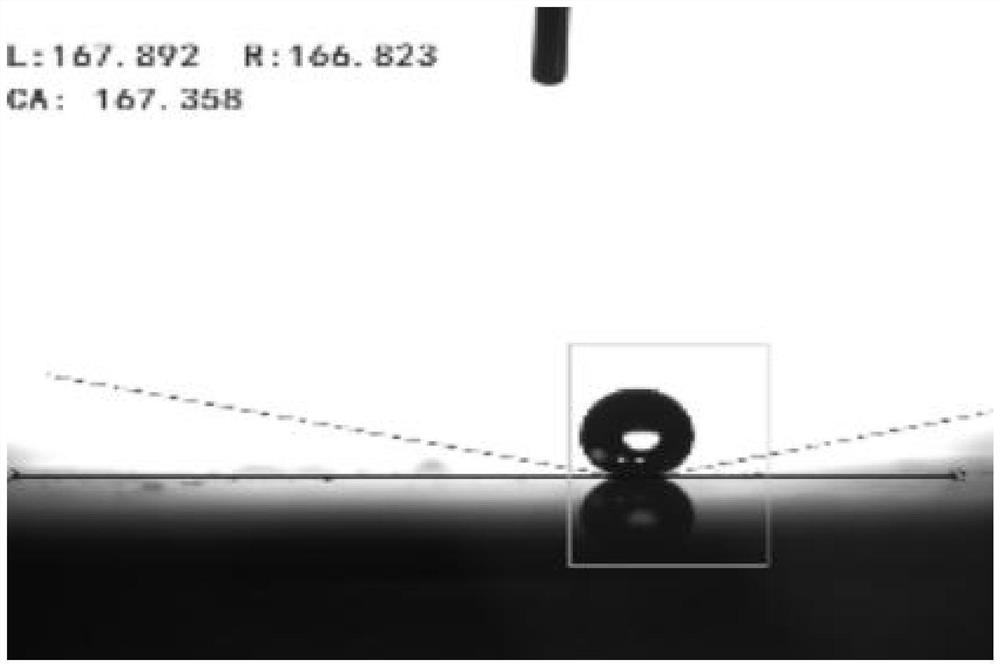

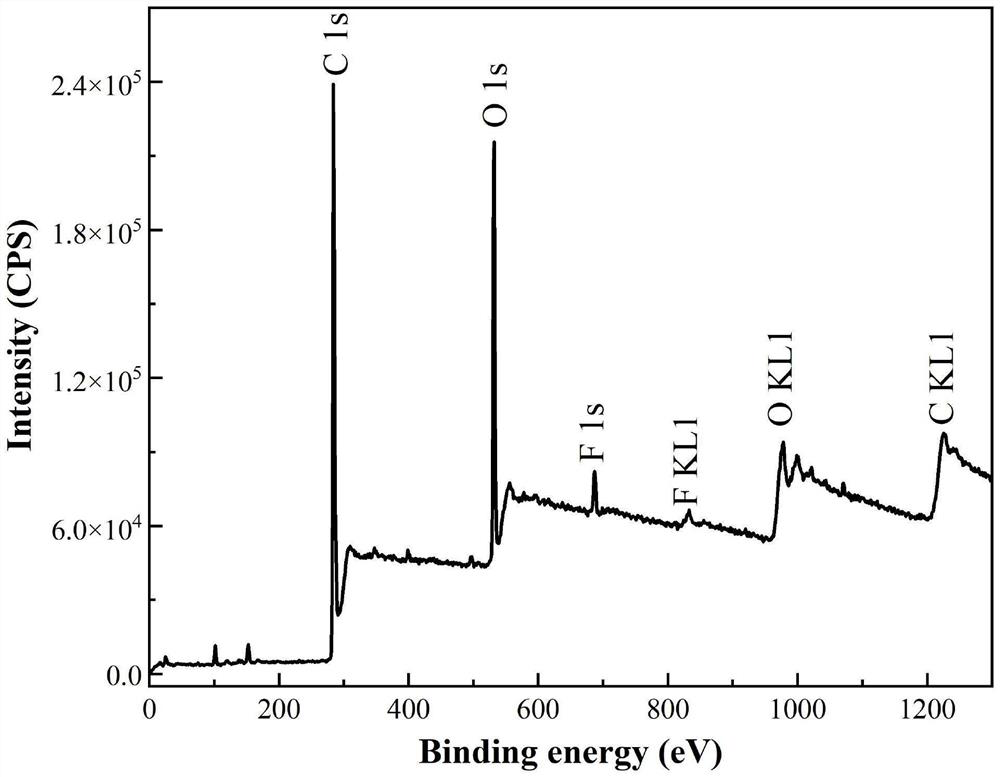

[0026] The present invention proposes a directional growth regulating method of a superhydrophobic nanostructure organic film, including the following steps:

[0027] (1) EtOAc EtOAc EtOAc EtOAc. The polytetrafluoroethylene targets were grinded to the surface of the sandpaper, and after substantially no scratch, the magnetron sputtering coating chamber was placed in an argon as a background atmosphere, and was pre-sputtered at a power 100W, a gas pressure 0.5 Pa. 10 min.

[0028] In the present embodiment, the metal substrate is described as an aluminum substrate as an example. In this step, the aluminum substrate is magneised to sputter.

[0029] (2) The distance between the Hall ion source and the metal substrate distance is 50 mm-300mm, regulates the Hall ion source, the anode voltage, the anode current, the filament current is 50V-300V, 3A-10A and 18A-4...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com