Dynamic measuring device of micro force

A technology of dynamic measurement and micro force, which is applied in the direction of measuring devices, measuring fluid pressure, instruments, etc., can solve the problems of limited progress in the application limit of microelectronics, marginal effects, etc., to achieve measurement span, adjustable accuracy, avoid The effect of the experimental conditions required

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

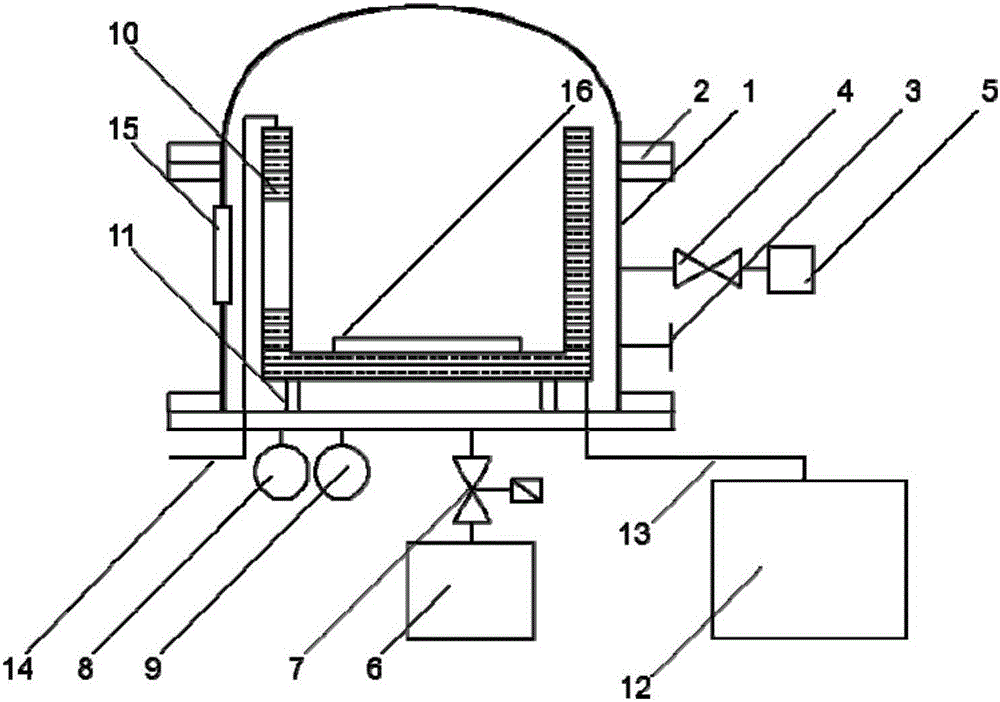

[0029] see figure 1 , figure 1It is a schematic diagram of the high-vacuum heat sink system in the micro-force dynamic measurement device of the present invention; the micro-force dynamic measurement device of the present invention includes three parts: a high-vacuum heat sink system, a magnetic levitation rotor system, and a speed measurement system. The high-vacuum heat sink system includes a The vacuum tank body 1 includes a heat sink 10 filled with liquid nitrogen inside the tank body. The inside of the cavity of the heat sink 10 is a magnetic levitation rotor system. Bolts are pressed and sealed, and the upper curved top cover is equipped with gas spring 2 to assist, which can be easily opened during assembly and debugging. There are three flange interfaces 3 on its side wall for connecting external circuits and interacting with other ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com