Metallographic corrosive agent of high nitrogen stainless steel and metallographic structure display method

A metallographic structure display and high-nitrogen stainless steel technology is applied in the field of metallographic etchant and metallographic structure display of high-nitrogen stainless steel. The effect of controllable corrosion process, clear metallographic structure and neat grain boundary

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

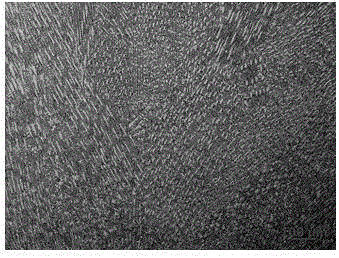

Image

Examples

Embodiment 1

[0019] Embodiment 1: The specific process of the method for displaying the metallographic structure of the present high-nitrogen stainless steel is as follows.

[0020] (1) Add 30ml of analytically pure hydrochloric acid to 60ml of ultrapure water, then add 30g of ferric chloride until dissolved, and finally add 30ml of analytically pure glycerol, stir with a glass rod until the solution is evenly mixed; the analytically pure (AR) The concentration of hydrochloric acid is 36wt% ~ 38wt%.

[0021] (2) Use a mosaic machine to embed the high-nitrogen stainless steel sample in phenolic resin, and polish the mosaic sample with 240#, 400#, 800#, 1000#, 1200# sandpaper on the polishing machine, and then polish it on the polishing machine A silk polishing cloth sprayed with 2.5 μm diamond polishing agent was used; the rotational speed during polishing was 750r / min, and the polishing time was 250s. The mosaic process is as follows: the holding temperature is 130° C., the holding time i...

Embodiment 2

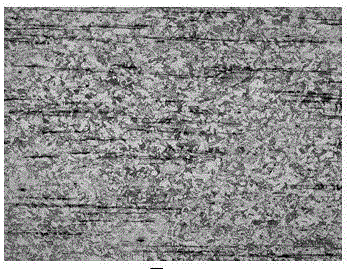

[0024] Embodiment 2: The specific process of the method for displaying the metallographic structure of the high nitrogen stainless steel is as follows.

[0025] (1) Add 25ml of analytically pure hydrochloric acid to 65ml of ultrapure water, then add 20g of ferric chloride until dissolved, and finally add 23ml of analytically pure glycerin, and stir with a glass rod until the solution is evenly mixed.

[0026] (2) Grind the inlaid high-nitrogen stainless steel samples with 240#, 400#, 800#, 1000#, and 1200# sandpaper in a polishing machine, and then use silk cloth sprayed with 2.5 μm diamond polishing agent on the polishing machine Polishing; the rotational speed during polishing is 750r / min, and the polishing time is 300s; the mosaic process is the same as that in Example 1.

[0027] (3) Immerse the polished sample in the corrosion solution and keep it for 40 seconds, the surface of the sample turns silver gray.

[0028] (4) Immediately after the corrosion is completed, rinse...

Embodiment 3

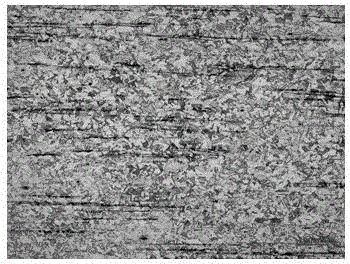

[0029] Embodiment 3: The specific process of the method for displaying the metallographic structure of the present high-nitrogen stainless steel is as follows.

[0030] (1) Add 20ml of analytically pure hydrochloric acid to 70ml of ultrapure water, then add 35g of ferric chloride until dissolved, and finally add 40ml of analytically pure glycerin, and stir with a glass rod until the solution is evenly mixed.

[0031] (2) Grind the inlaid high-nitrogen stainless steel samples with 240#, 400#, 800#, 1000#, and 1200# sandpaper in a polishing machine, and then use silk cloth sprayed with 2.5 μm diamond polishing agent on the polishing machine Polishing; the rotational speed during polishing is 700r / min, and the polishing time is 360s; the mosaic process is the same as that in Example 1.

[0032] (3) Immerse the polished sample in the corrosion solution and keep it for 60 seconds, the surface of the sample turns silver gray.

[0033] (4) Immediately after the corrosion is complete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com