Method for preparing high purity kerogen

A kerogen and sample technology, applied in the field of petroleum geological exploration, can solve the problems of large loss of kerogen, failure to represent the overall characteristics, differentiation, etc., and achieve the effects of data stability, dispersibility and originality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Example 1: Preparation of high-purity kerogen from Datangpo Formation black shale in Well ZK2105

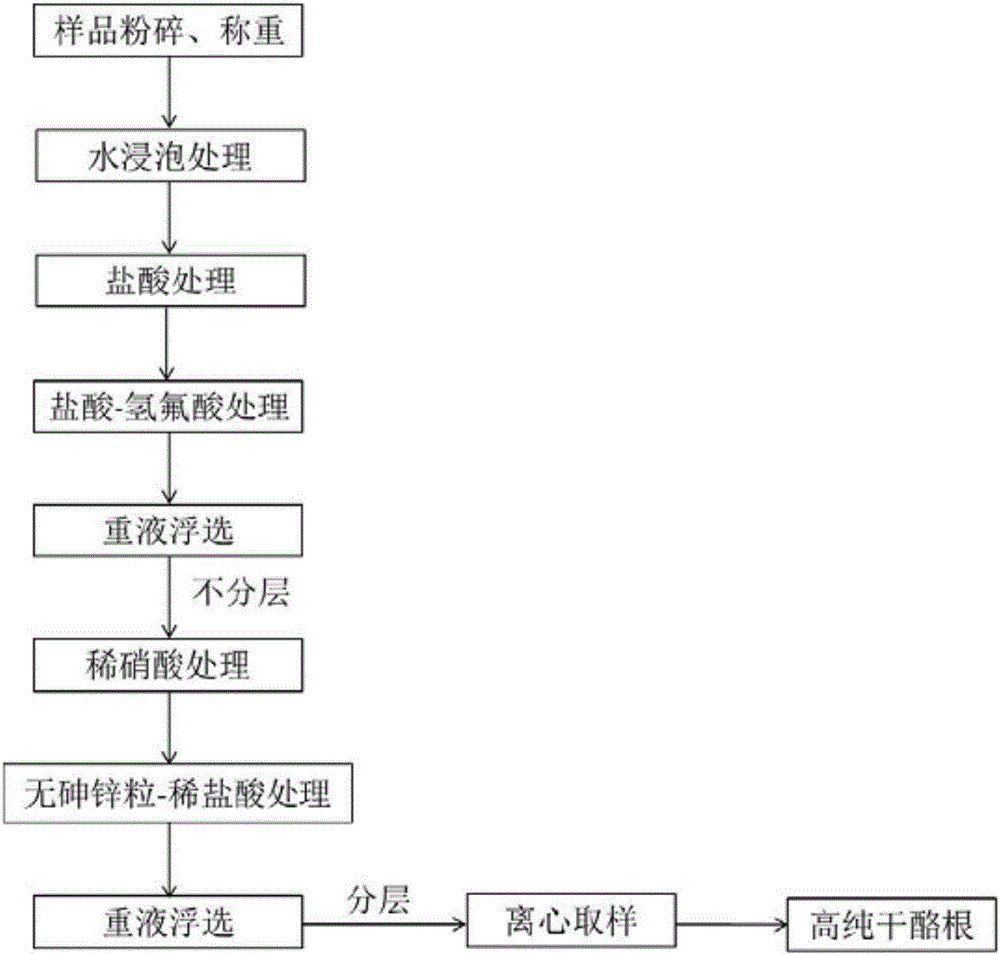

[0047] This embodiment 1 according to figure 1 The described process prepares high-purity kerogen, that is, the sample is pulverized and weighed first, and then subjected to hydrochloric acid treatment, hydrochloric acid-hydrofluoric acid treatment, and heavy liquid flotation test. If it is found that the sample cannot be effectively stratified, then the mass The sample after hydrochloric acid-hydrofluoric acid treatment is treated with dilute nitric acid with a fraction of 1-5%, followed by treatment with arsenic-free zinc particles-dilute hydrochloric acid, and heavy liquid flotation stratification to obtain high-purity kerogen.

[0048] The specific implementation steps are as follows:

[0049] (1) choose 50g organic carbon content to be the rock core sample of 3.5wt%, pulverize, cross 80 mesh stainless steel sieves, get the sample of particle size<0.18mm and be used f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com