An experimental device for simulating the solubility and injectability of polymers

An experimental device and injection technology, which can be used in measurement devices, instruments, scientific instruments, etc., and can solve problems such as poor polymer flooding and injection effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific implementation of the present invention will be further described below in conjunction with the examples, which does not limit the present invention to the scope of the described examples.

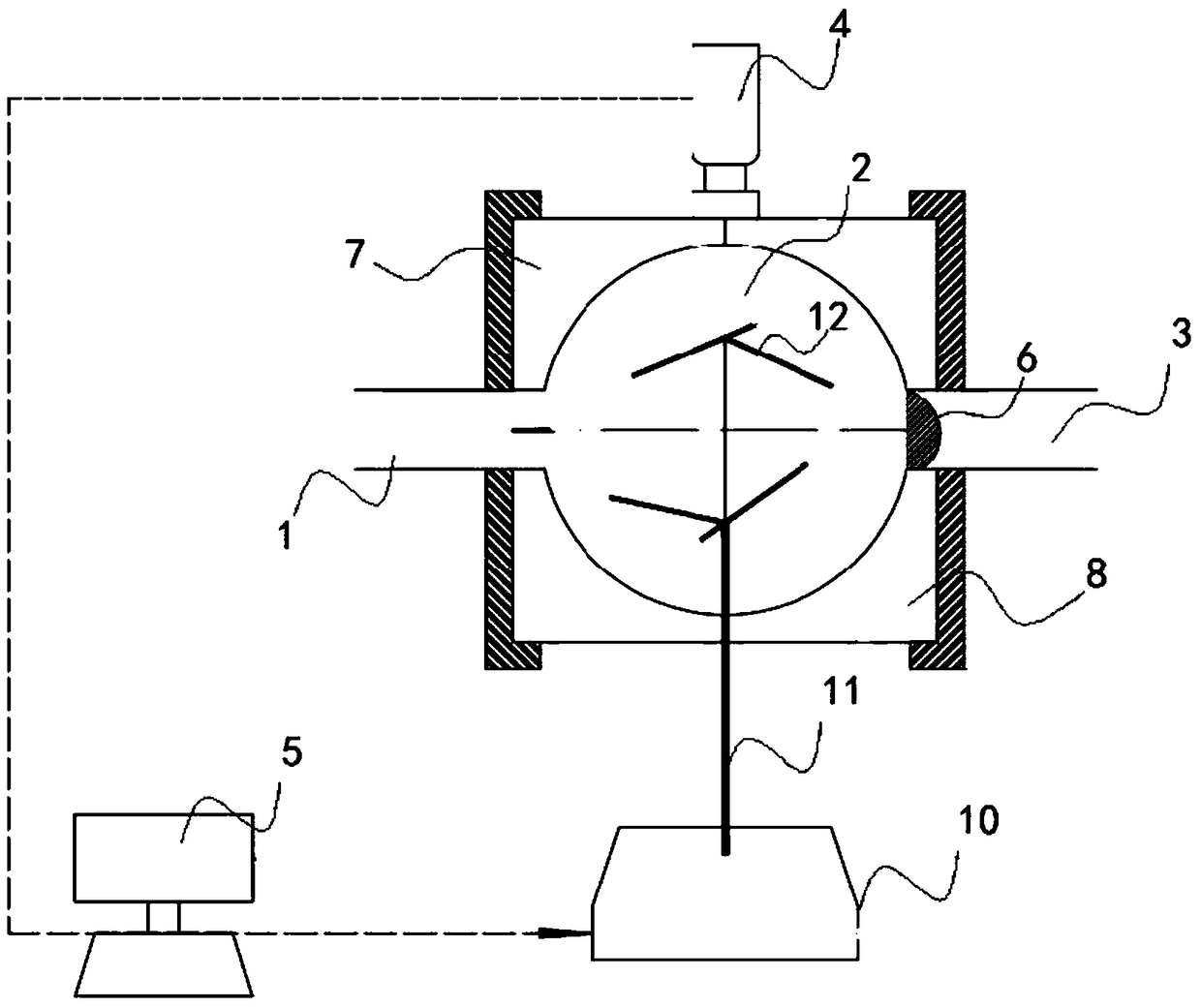

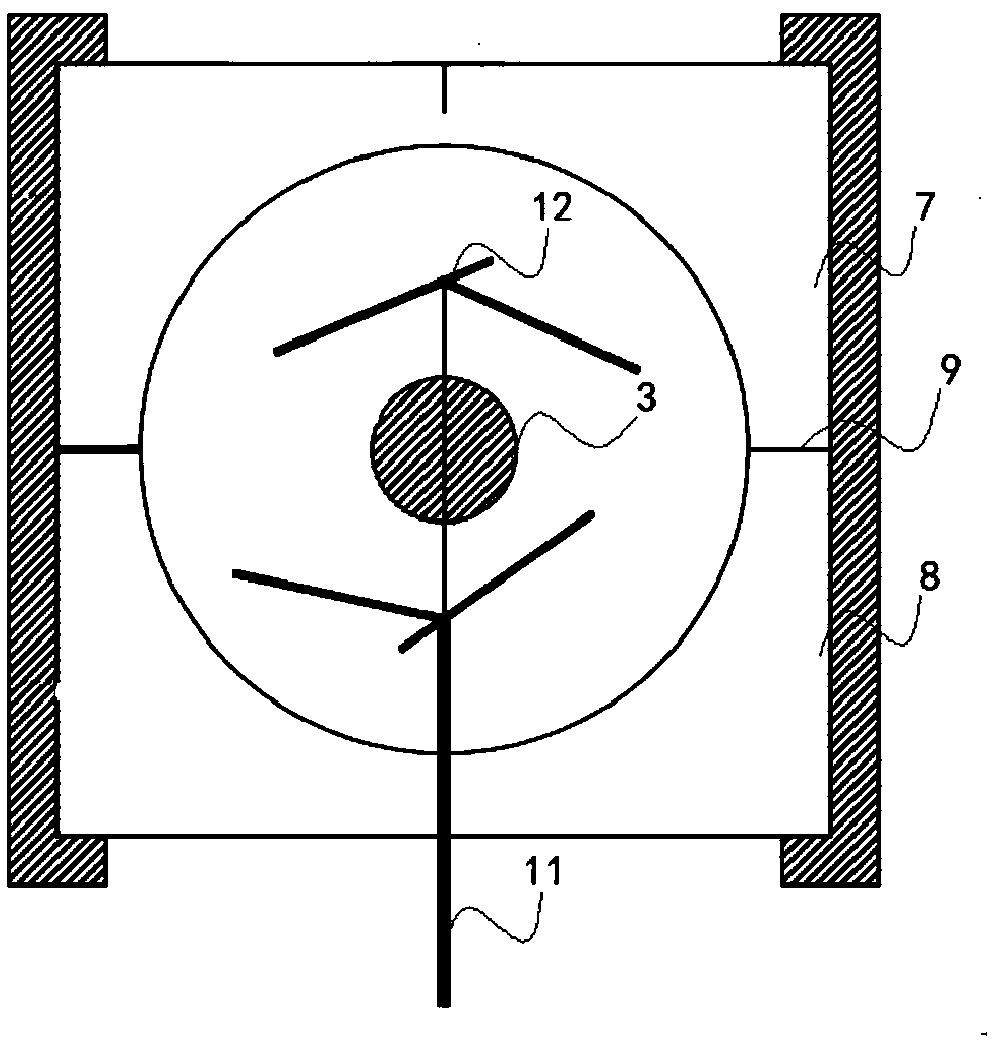

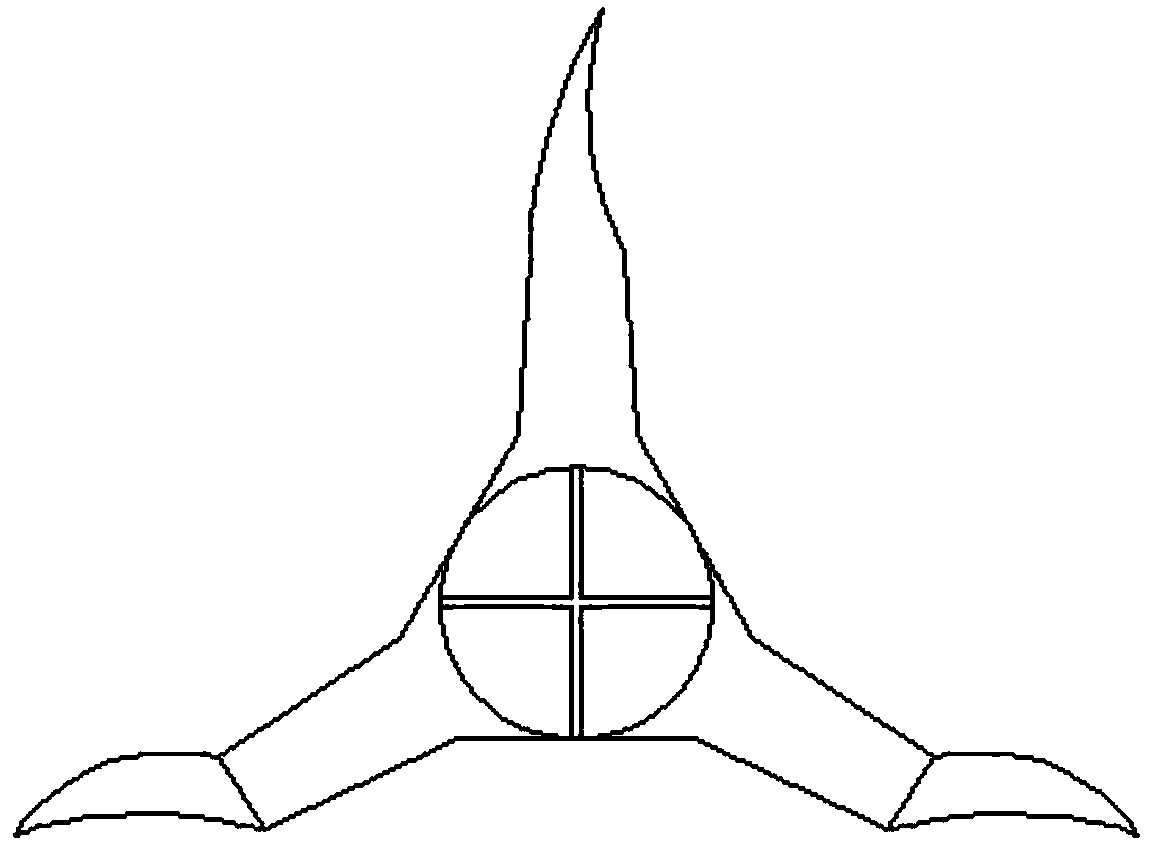

[0018] Such as Figure 1 to 3 As shown, an experimental device for simulating the degree of polymer dissolution and injectability includes a cavity with an outer square and an inner circle, a pressure sensing system 4, a PC machine 5, and a shearing device. The connected liquid inlet channel 1, the spherical cavity 2, the liquid outlet channel 3, the shearing device is installed in the spherical cavity 2, and the outlet channel 3 is provided with a filter cake 6, which is determined by the diameter A round cake made by winding and pressing a 1mm thin stainless steel tube has stronger pressure resistance than ordinary filter membranes. The pressure sensing system 4 has a pressure collection connector, and the pressure sensing system 4 is installed outside On the upper end ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com