SCR outlet flue cross section nitric oxide and oxygen concentration online monitoring method and system

A technology for outlet flue and nitrogen oxides, which is applied in the direction of chemical instruments and methods, separation methods, measuring devices, etc., can solve the problems of affecting the performance test and adjusting the progress of the test work, affecting the accuracy of test results, and low test work efficiency. , to achieve the effect of shortening the monitoring time, improving comparability and improving monitoring efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings.

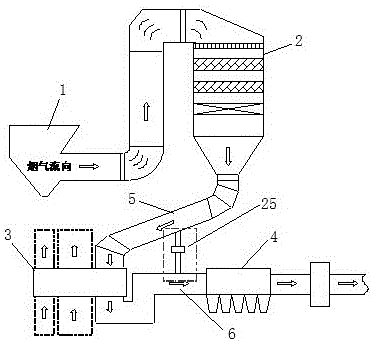

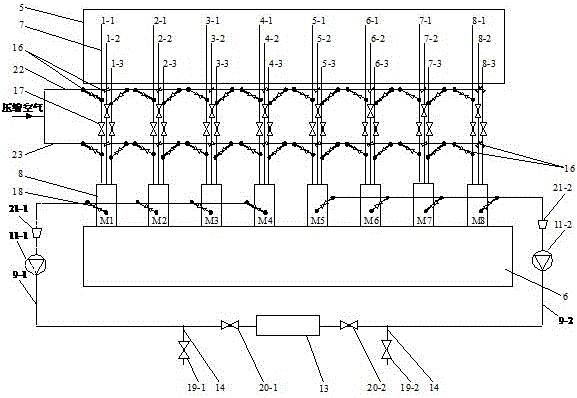

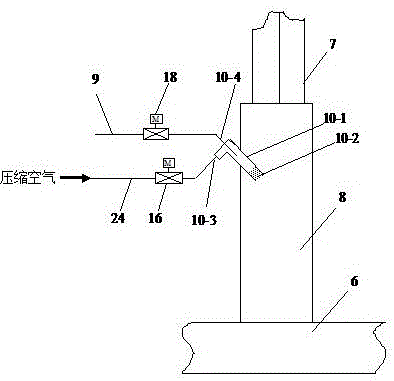

[0023] Such as figure 1 , figure 2As shown, the online monitoring system 25 of nitrogen oxides and oxygen concentration field in the cross-section of the SCR channel of the present invention is mainly composed of a flue gas sampling system, a compressed air pipeline, a control system and a flue gas analysis system. The flue gas sampling system is composed of flue gas sampling branch pipe 7, flue gas sampling main pipe 8, clean flue gas pipe 9, filter 10, condenser 21-1, 21-2, sampling pump 11-1, 11-2, exhaust Empty pipe 14 is composed. According to the cross-sectional size of the SCR outlet flue, arrange the flue gas sampling and measuring points according to the layout principle of the grid method (here set to 8*3: 1-1, 1-2, 1-3, 1-1, 2-2, 2-3, 3-1, 3-2, 3-3, 4-1, 4-2, 4-3, 5-1, 5-2, 5-3, 6-1, 6-2, 6- 3, 7-1, 7-2, 7-3, 8-1, 8-2, 8-3). The flue gas sampling bra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com