Product irradiation dose determination method

A technology of radiation dose and measurement method, which is applied in the fields of measuring γ, calculating product radiation dose, electron beam and X-ray product radiation dose, and can solve the problem that the radiation dose cannot be given, that it cannot be remedied after the event, and that it cannot be obtained. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] Embodiment 1. Routine measurement of radiation absorbed dose of gloves (packed in cartons).

[0065] 1. First establish a standard curve:

[0066] ①The paper is taken from 2 glove cartons and cut into 2×6 pieces of 10×10cm 2 size sample, the CO 60 Gamma irradiation upper irradiation (1.25MeV), dose setting 0, 8, 16, 24, 36, 44kGy;

[0067] ②The moisture content of the paper was determined to be 8.7%, and the temperature of the irradiation room was 24°C;

[0068] ③ After the irradiation is completed, extract the paper material from the inner side of the paper block, weigh 100mg, roll it into a straight tube, insert it into the ESR test tube along the tube wall, push it into the bottom of the tube with a fork-shaped stainless steel spatula, and compact it to make the sample The height is less than 3cm;

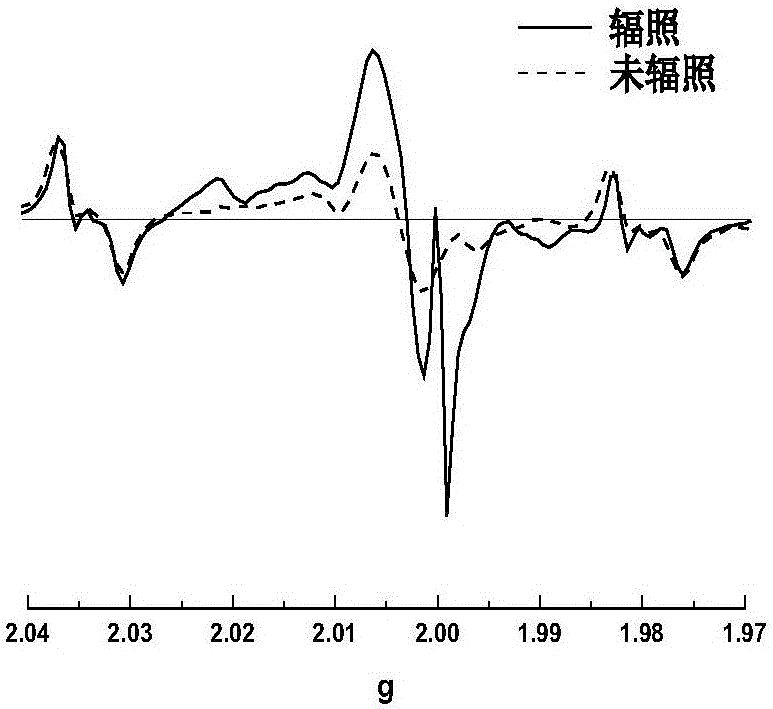

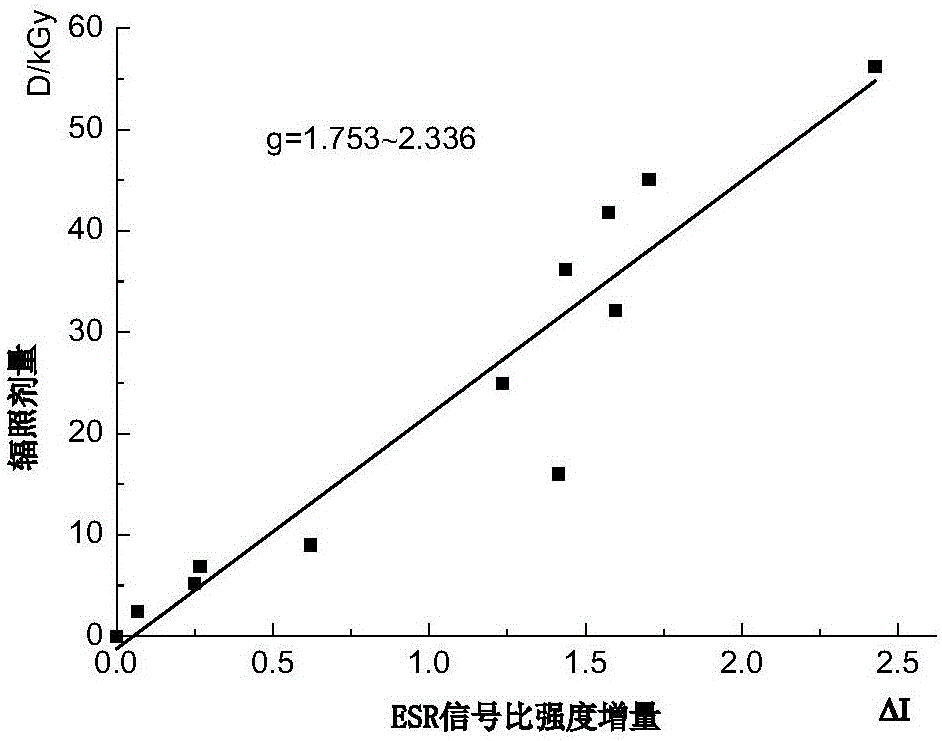

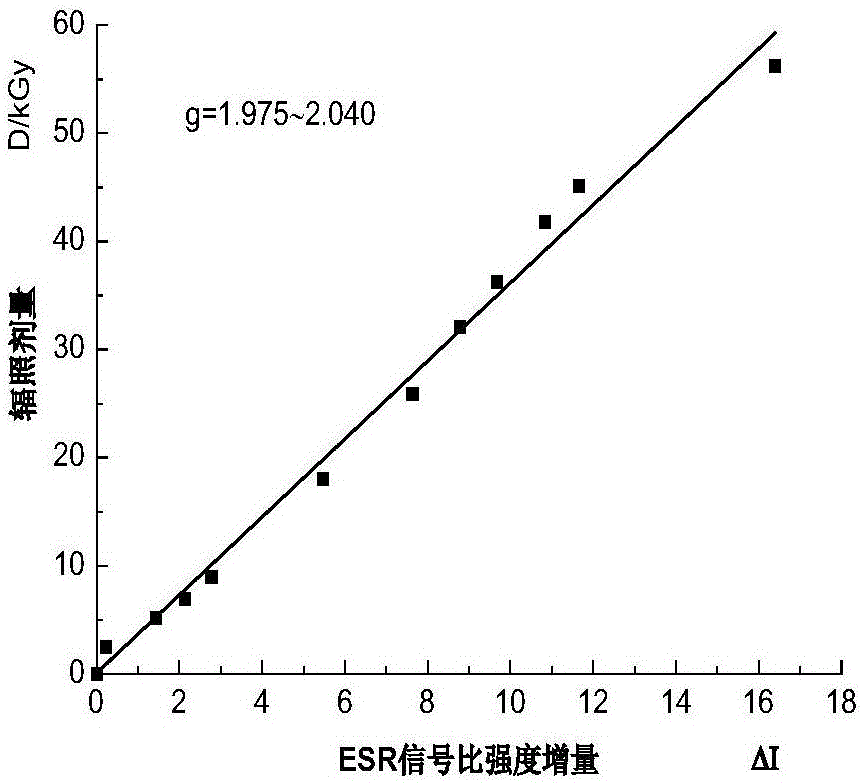

[0069] ④ESR measurement: ESR measurement was completed on the 10th day, and the working conditions of the instrument were: X-band 9.8GH, power 20mW; central magnetic ...

Embodiment 2

[0076] Embodiment 2. Determination of radiation absorbed dose of pet food (carton packaging).

[0077] 1. First establish a standard curve:

[0078] ①The paper is taken from 4 pet food cartons and cut into 4×7 pieces of 10×10cm 2 Large and small samples, irradiated on the electron accelerator (10.0MeV), the dose setting is 0, 1.5, 4, 6, 8, 12, 24kGy;

[0079] ②The moisture content of the paper is determined to be 10.0%, and the temperature of the irradiation room is 40°C;

[0080] ③ After the irradiation is completed, extract the paper material from the inner side of the paper block, weigh 300mg, roll it into a straight tube, insert it into the ESR test tube along the tube wall, push it into the bottom of the tube with a fork-shaped stainless steel shovel, and compact it to make the sample The height is less than 3cm;

[0081] ④ESR measurement: ESR measurement was completed on the third day, and the working conditions of the instrument were: X-band 9.85GH, power 5.024mW; ce...

Embodiment 3

[0087] Embodiment 3, the radiation absorbed dose determination of medical dressing (carton packaging).

[0088] 1. First establish a standard curve:

[0089] ①The paper materials are taken from 4 medical dressing cartons and cut into 4×5 pieces of 10×10cm 2 Large and small samples are irradiated on the X-ray target (5.0MeV), and the dose is set to 0, 8, 12, 16, 24kGy;

[0090] ②The moisture content of the paper is determined to be 8.0%, and the temperature of the irradiation room is 38°C;

[0091] ③ After the irradiation is completed, extract the paper material from the inner side of the paper block, weigh 250 mg, roll it into a straight tube, insert it into the ESR test tube along the tube wall, push it into the bottom of the tube with a fork-shaped stainless steel shovel, and compact it to make the sample The height is less than 3cm;

[0092] ④ESR measurement: ESR measurement was completed on the third day, and the working conditions of the instrument were: X-band 9.8GH, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com