Aluminum-plastic film structure for secondary rechargeable soft package battery

A soft-pack battery and secondary charging technology, which is applied in the field of aluminum-plastic film structure, can solve the problems of electro-hydraulic outflow corrosion circuit short circuit, insulation layer sinking ability decline, and aluminum-plastic film low insulation, so as to prevent corrosion and increase High temperature resistance and corrosion resistance, not easy to break through

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

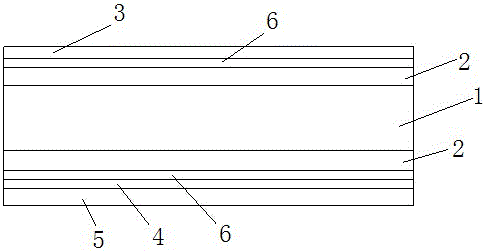

[0013] Embodiment: A kind of aluminum-plastic film structure of rechargeable soft pack battery, such as figure 1 As shown, it includes an aluminum layer 1 with an anti-corrosion layer 2 on the upper and lower sides. The two anti-corrosion layers 2 are respectively bonded with an outer protective layer 3 and an insulating inner layer. The insulating inner layer includes an aluminum layer 1 bonded to The first insulating layer 4 on the lower surface of the corrosion layer 2 on the lower side, and the second insulating layer 5 bonded to the lower surface of the first insulating layer 4; wherein the first insulating layer 4 is the PET layer, the PI layer and the PBT layer One, the second insulating layer 5 is one of CPP layer, PP layer, EAA layer and PE layer. The thickness ratio of the first insulating layer 4 and the second insulating layer 5 is 1:20˜1:2. The combination of PI and PP materials for the first insulating layer 4 and the second insulating layer 5 is the most effect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com