A modified α-alumina carrier and its preparation and application

A technology of alumina support and modification, applied in catalyst support, chemical instruments and methods, metal/metal oxide/metal hydroxide catalyst, etc., can solve the problem of poor activity, poor selectivity and good activity And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

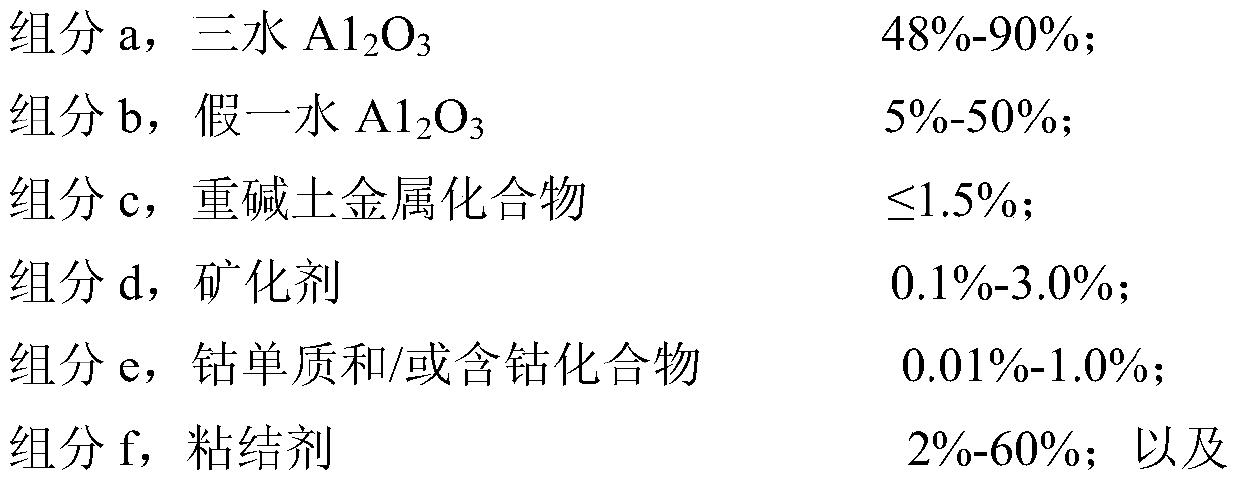

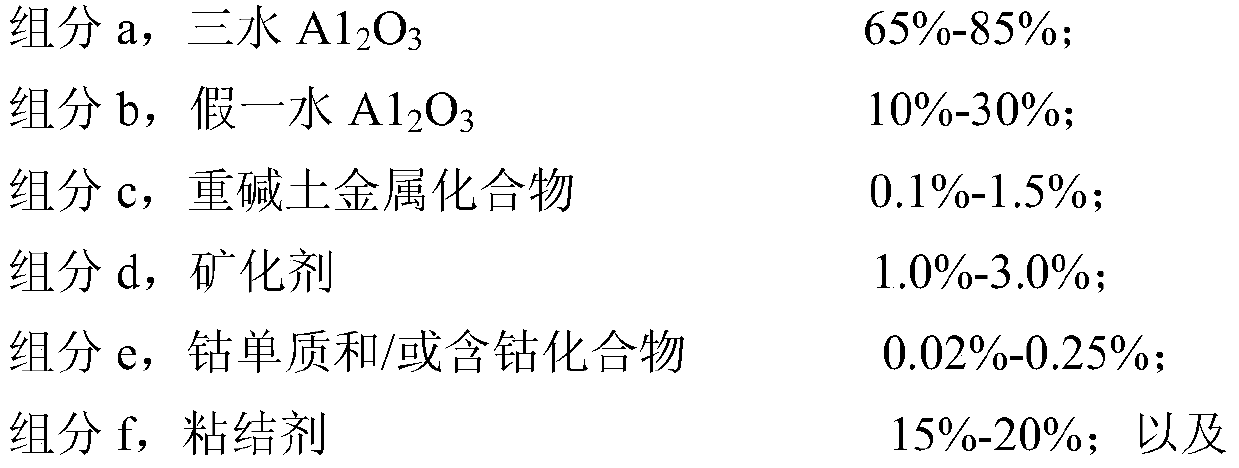

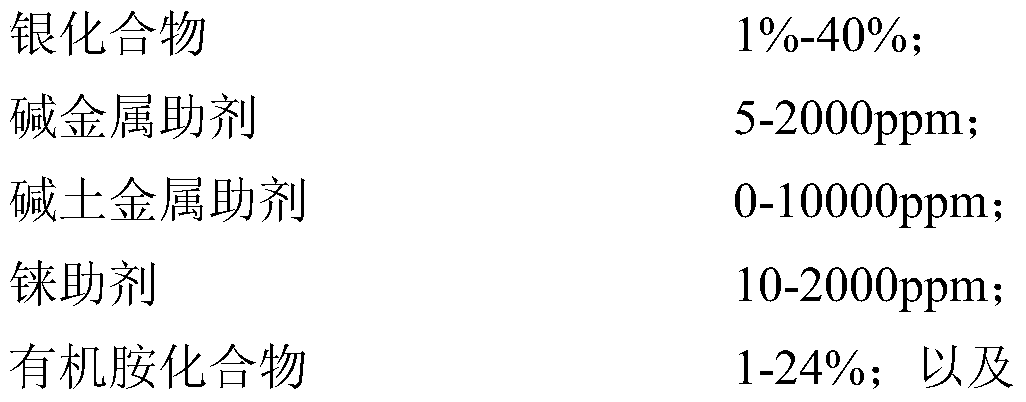

[0071] The second aspect of the present invention provides a method for preparing the modified α-alumina carrier as described in the first aspect of the present invention, which includes:

[0072] Step A, mixing components a-g to prepare a cobalt-containing α-alumina carrier precursor mixture;

[0073] Step B, molding the cobalt-containing α-alumina carrier precursor mixture, drying and calcining to obtain a cobalt-containing α-alumina carrier;

[0074] Step C, treating the cobalt-containing α-alumina carrier with an acid solution to obtain a modified α-alumina carrier precursor;

[0075] Step D, washing, drying and calcining the modified α-alumina carrier precursor to obtain a modified α-alumina carrier;

[0076] Wherein, in step C, the cobalt-containing α-alumina carrier is treated with an acid solution using an aqueous solution of an acidic compound.

[0077] According to the method of the present invention, the composition of the cobalt-containing α-alumina carrier precu...

Embodiment 1

[0151] Prepare 400 g of 0.5 mol / L HNO at a weight ratio of α-alumina carrier to aqueous acidic compound solution of 1:20 3 solution, and the HNO 3 Heat the solution to 80°C, weigh 20g Z-2 carrier and put it into HNO 3 After the solution was stirred for 0.5 h, the acid liquid α-alumina carrier precursor was taken out and washed with deionized water until the pH value of the filtrate was about 7. Then put the acid liquid α-alumina carrier precursor into an oven and dry at 100°C for 10 hours, and then put the dried acid liquid α-alumina carrier precursor into a muffle furnace and roast at 540°C for 4 hours to obtain a modified α - Alumina support. The prepared modified α-alumina carrier was named Z-4, and its crushing strength, water absorption and specific surface area were measured. The results are shown in Table 2.

Embodiment 2

[0153]Prepare 400g of 0.01mol / L HNO at a weight ratio of α-alumina carrier to aqueous acidic compound solution of 1:20 3 solution, and the HNO 3 Heat the solution to 80°C, weigh 20g Z-2 carrier and put it into HNO 3 After the solution was stirred for 0.5 h, the acid liquid α-alumina carrier precursor was taken out and washed with deionized water until the pH value of the filtrate was about 7. Then put the acid liquid α-alumina carrier precursor into an oven and dry at 100°C for 10 hours, and then put the dried acid liquid α-alumina carrier precursor into a muffle furnace and roast at 540°C for 4 hours to obtain a modified α - Alumina support. The prepared modified α-alumina carrier was named Z-5, and its crushing strength, water absorption and specific surface area were measured, and the results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com