Iron-based catalyst for direct synthesis of low-carbon olefins from synthesis gas and preparation method thereof

A technology of low-carbon olefins and catalysts, which is applied in the field of catalysts and their preparation, and can solve problems such as easy overheating, difficulty in removing heat from reactions, and low weight selectivity of low-carbon olefins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

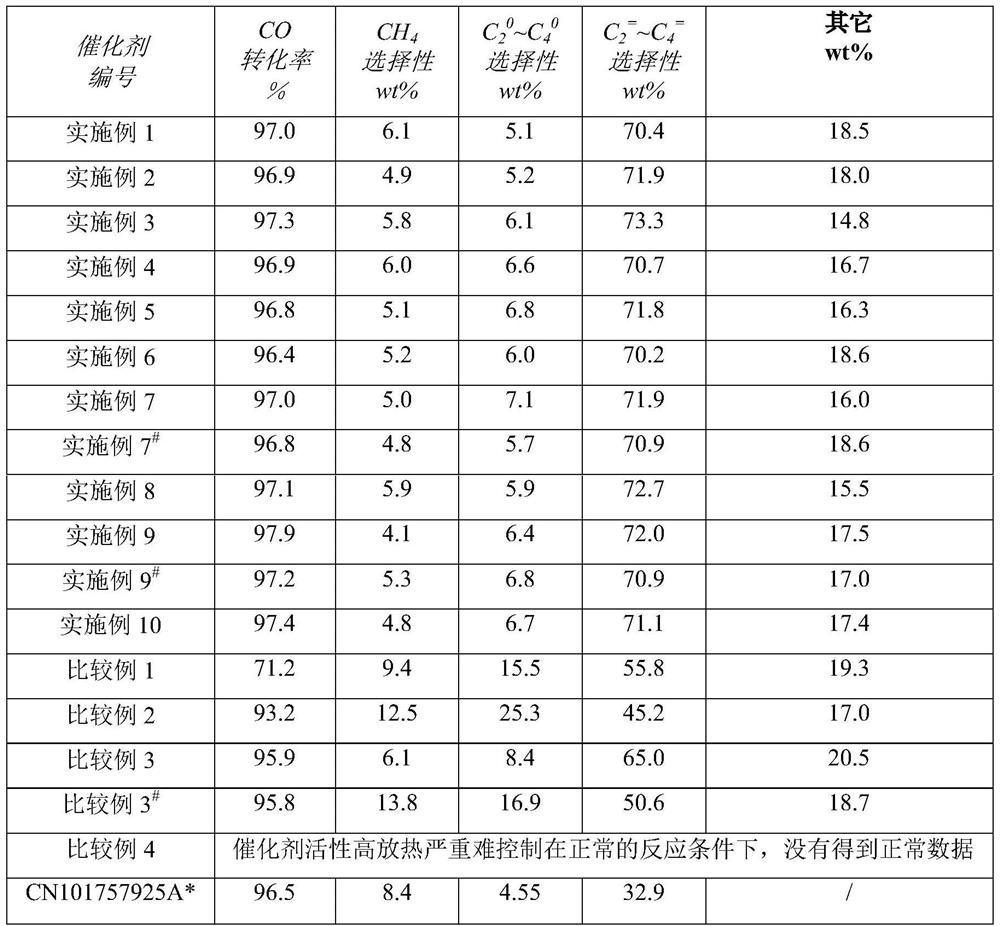

Examples

Embodiment 1

[0024] Get 40.0g titanyl sulfate and be dissolved in the water of 1000ml, be made into the titanyl sulfate solution of 0.25mol / L, this solution and the ammoniacal liquor of 400g 5% by weight co-current sedimentation and centrifugal separation, after washing three times with deionized water, fresh Titanium oxide precipitation I;

[0025] Get 606.03g of ferric nitrate nonahydrate and dissolve it in a certain amount of water to form solution II;

[0026] Mix solution II with precipitate I, and peptize in a water bath at 40°C for 24 hours to obtain colloidal slurry III;

[0027] Dissolve 0.084g of potassium hydroxide in 1.00g of water to make potassium hydroxide solution

[0028] Cool the slurry III to 10°C in a water bath at 10°C, then add the above-mentioned potassium hydroxide to the cooled slurry III, and mix and beat at 10°C;

[0029] Then add the dilute sulfuric acid of 0.098g 15% by weight in the above-mentioned slurry;

[0030] Finally, adjust the pH value of the slurry...

Embodiment 2

[0035] Get 1072g zirconium nitrate pentahydrate and be dissolved in the water of 2500ml, be made into the zirconium nitrate solution of 0.8mol / L, this solution and the ammoniacal liquor of 800g 25% by weight co-currently precipitate and centrifuge, wash with deionized water three times to obtain fresh Zirconia Precipitation I;

[0036] Get 606.03g of ferric nitrate nonahydrate and dissolve it in a certain amount of water to form solution II;

[0037] Mix solution II and precipitate I, and peptize in a water bath at 100°C for 0.5h to obtain colloidal slurry III;

[0038]Dissolve 20.47g cesium nitrate in 50.0g water to make cesium nitrate solution;

[0039] Add the above-mentioned cesium nitrate solution into the slurry III in a water bath at 100°C, and mix and beat at 100°C;

[0040] Then add 19.6g of 15% by weight dilute phosphoric acid in the above slurry;

[0041] Finally, the pH value of the slurry was adjusted to 1 with dilute nitric acid to obtain a uniform slurry IV (...

Embodiment 3

[0046] Get 80.0g titanyl sulfate and be dissolved in the water of 2000ml, be made into the titanyl sulfate solution of 0.25mol / L, centrifuge after this solution and 800g 5% by weight of ammonia water co-flow precipitation, get fresh after washing three times with deionized water Titanium oxide precipitation I;

[0047] Get 367.43g ferric citrate and dissolve in a certain amount of water to form solution II;

[0048] Mix solution II with precipitate I, and peptize in a water bath at 70°C for 12 hours to obtain colloidal slurry III;

[0049] Dissolve 4.8g sodium hydroxide in 10.00g water to make potassium hydroxide solution

[0050] Cool the slurry III to 40°C in a water bath at 40°C, then add the above-mentioned potassium hydroxide to the cooled slurry III, and mix and beat at 40°C;

[0051] Then add the dilute sulfuric acid of 0.294g 15% by weight in the above-mentioned slurry;

[0052] Finally, adjust the pH value of the slurry with dilute ammonia water to be 3 to obtain a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com