Catalyst for preparing low-carbon olefin from synthesis gas and preparation method thereof

A low-carbon olefin and catalyst technology, applied in the field of catalysts and their preparation, can solve the problems of easy deactivation of catalysts, low yield of low-carbon olefins, easy flying temperature and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

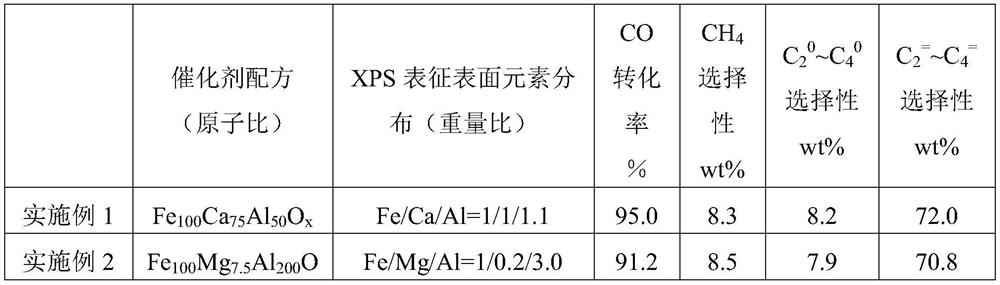

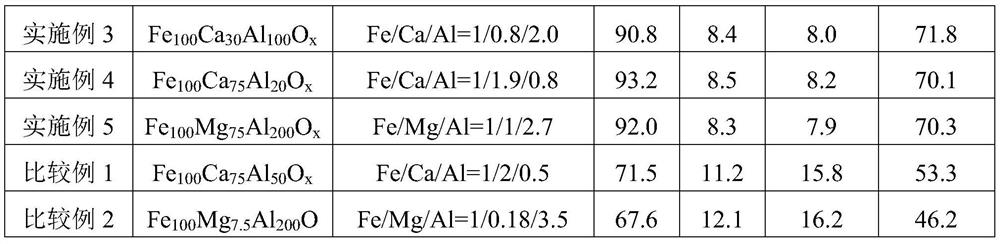

Examples

Embodiment 1

[0051] 1) Catalyst preparation:

[0052] Take 1mol of Fe(NO 3 ) 3 9H 2 O was dissolved in water to make a 0.5mol / L Fe solution, and the solution was separated with 1350g 5wt% ammonia water for co-current precipitation, and washed three times with acetone to obtain fresh Fe(OH) 3 Precipitation I; dry the precipitate under reduced pressure at 100°C, and then roast at 500°C for 2 hours to obtain iron oxide powder; take 0.5mol of Ca(NO 3 ) 2 4H 2 O is dissolved in water to form a 40wt% Ca element solution; get 30% Al sol containing 0.5mol; mix and beat the above-mentioned Ca element solution, Al sol and iron oxide powder at 80°C; Concentration is 25wt% nitric acid to adjust the pH value of slurry to be 2, obtain slurry (solid content 40%); Slurry is spray-dried and molded, and spray machine inlet temperature is 320 ℃, and outlet temperature is 190 ℃; Then roasting, roasting The temperature is 600°C, the calcination time is 3h, and the catalyst particles for microspherical fl...

Embodiment 2

[0071] 1) Catalyst preparation:

[0072] Take 1mol of Fe(NO 3 ) 3 9H 2 O is dissolved in water and made into a 0.5mol / L Fe solution. The solution is co-currently precipitated with 1350g 5wt% ammonia water and separated, and washed with ethanol three times to obtain fresh Fe(OH) 3 Precipitation I; vacuum-dry the precipitate at 100°C, then roast at 600°C for 2h to obtain iron oxide powder; take 0.075mol of Mg(NO 3 ) 2 ·6H 2 O is dissolved in water to form a 40wt% Mg element solution; take 30% Al sol containing 2mol; mix and beat the above-mentioned Mg element solution, Al sol, and iron oxide powder at 80°C; The pH value of the slurry is adjusted to 1 for 25wt% nitric acid to obtain the slurry (solid content 40%); the slurry is spray-dried and molded, the sprayer inlet temperature is 320 ° C, and the outlet temperature is 190 ° C; then roasted, the roasting temperature 600°C, calcination time 3h, to obtain catalyst particles for microspherical fluidized bed, the composition...

Embodiment 3

[0091] 1) Catalyst preparation:

[0092] Take 1mol of Fe(NO 3 ) 3 9H 2 O was dissolved in water to make a 0.5mol / L Fe solution, and the solution was separated with 1350g 5wt% ammonia water for co-current precipitation, and washed three times with acetone to obtain fresh Fe(OH) 3 Precipitation I; dry the precipitate under reduced pressure at 100°C, and then roast at 500°C for 2 hours to obtain iron oxide powder; take 0.3mol of Ca(NO 3 ) 2 4H 2 O is dissolved in water to make a 40wt% Ca element solution; take 30% Al sol containing 1mol; mix and beat the above Ca element solution, Al sol, and iron oxide powder at 80°C; The pH value of 25wt% nitric acid adjustment slurry is 2, obtains slurry (solid content 40%); Slurry is spray-dried and molded, spray machine inlet temperature is 320 ℃, outlet temperature 190 ℃; Carry out roasting then, roasting temperature 600°C, calcination time 3h, to obtain catalyst particles for microspherical fluidized bed, the composition of which is:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com