CRT display device glass shell disassembly and recovery apparatus system and CRT display device glass shell disassembly and recovery method

A CRT display and recovery system technology, applied in the field of waste resource recycling, can solve the problems of low recovery rate of fluorescent powder, low efficiency of manual dismantling, dust pollution, etc., to improve the quality of the working environment, save manpower, and increase production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

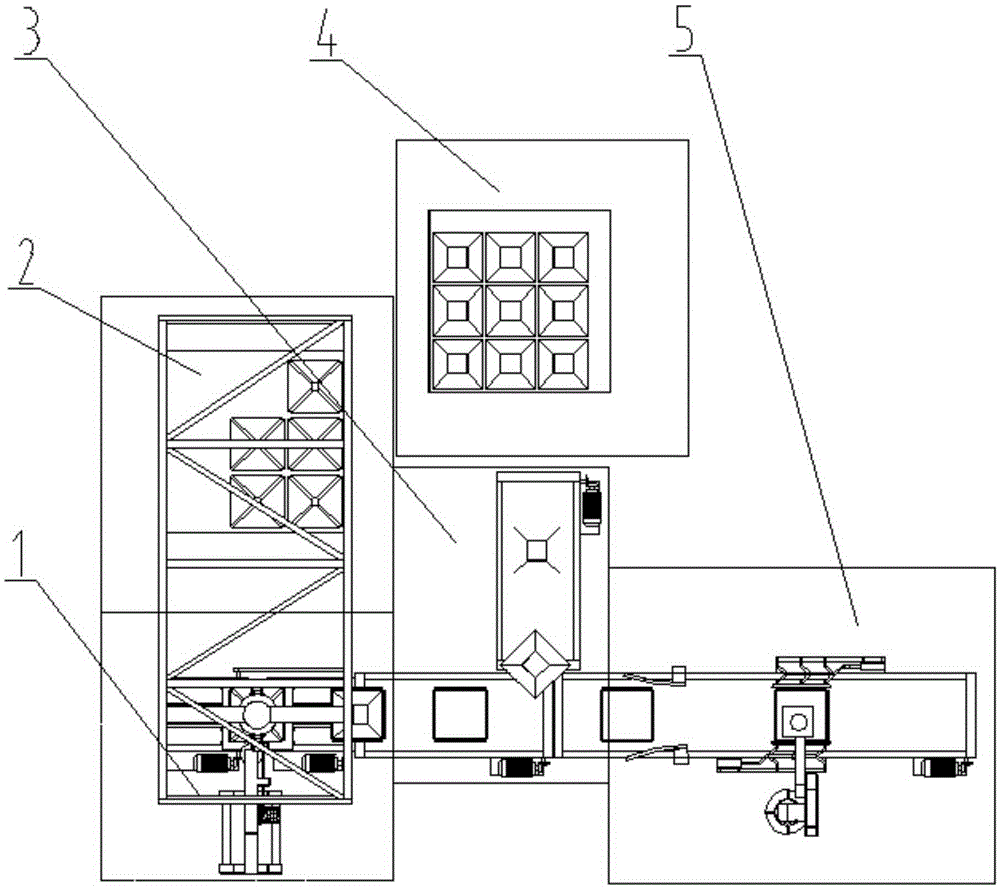

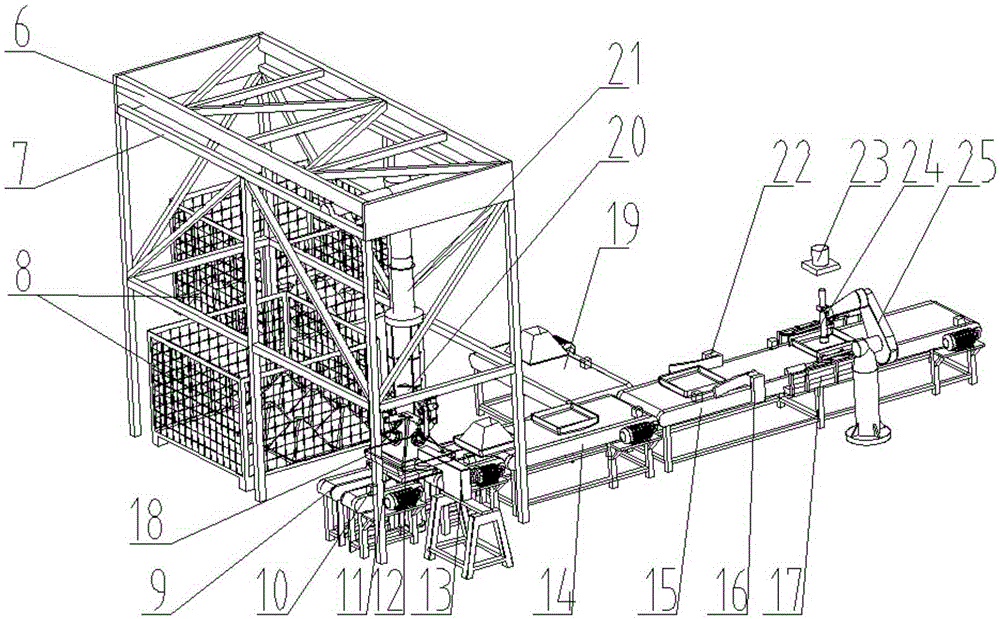

[0029] Specific implementation mode one, combined with the attached figure 1 , 2Illustrate this embodiment, a kind of CRT display fluorescent powder recovery device system, is made up of cone glass storage area 2, cone glass cutting separation area 1, shadow mask separation area 3, shadow mask storage area 4 and fluorescent powder recovery area 5; The storage area 2 is placed with a cargo cage 8; the tapered glass cutting and separating area 1 is equipped with a material conveying line 9, a Cartesian robot 21, a truss 6, a tapered glass gripper 20, a vision system 12, a heating wire winding device 13, and a cooling device 18, supporting the rotating platform 11, the photoelectric switch 10; the input end of the material conveying line 1 is the entrance of the glass bulb of the CRT display, and the output end is connected with the material conveying line 2 14, and the material conveying line 2 14 is located in the shadow mask separation area 3; right angle The coordinate robot...

specific Embodiment approach 2

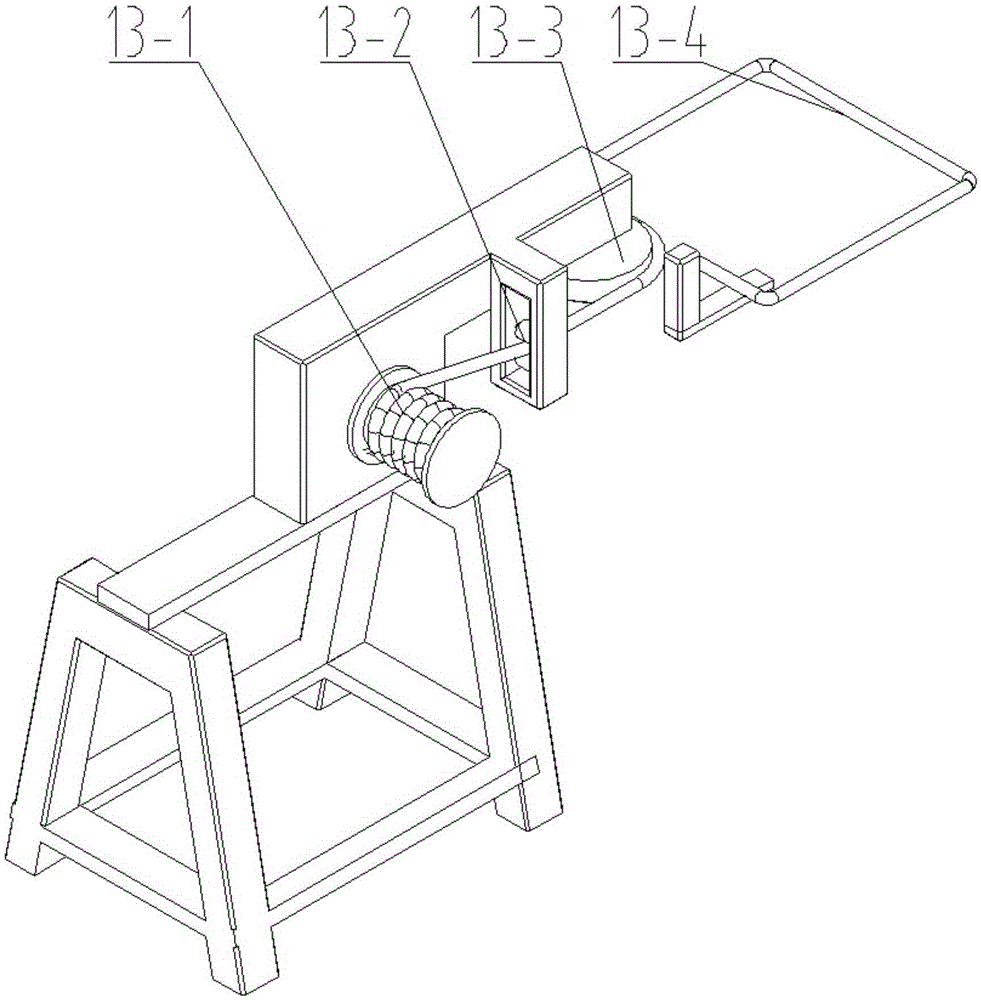

[0030] Specific implementation mode two, combined with the attached figure 1 , 2 3. Describe this embodiment. The difference between this embodiment and Embodiment 1 is that the heating wire winding device is composed of a wire barrel, a heating wire tensioning device, a heating wire and a heating wire guide wheel. Other parts are the same as in the first embodiment.

specific Embodiment approach 3

[0031] Specific implementation mode three, combined with the attached figure 1 , 2 Describe this embodiment. The difference between this embodiment and Embodiment 1 is that the material conveying line can be a belt conveying line or a roller conveying line; the material conveying line refers to material conveying line 1, material conveying line 2, material conveying line Three and material conveying line four, other parts are the same as the specific embodiment one.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com