Material sandblasting, washing and drying processing line and its process

A technology for washing, drying, and processing lines, applied in drying, dryers, metal processing equipment, etc., can solve the problems of reducing production rhythm, large structure space, and increasing labor intensity of employees, reducing labor intensity and ensuring drying. Drying effect, the effect of improving the drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

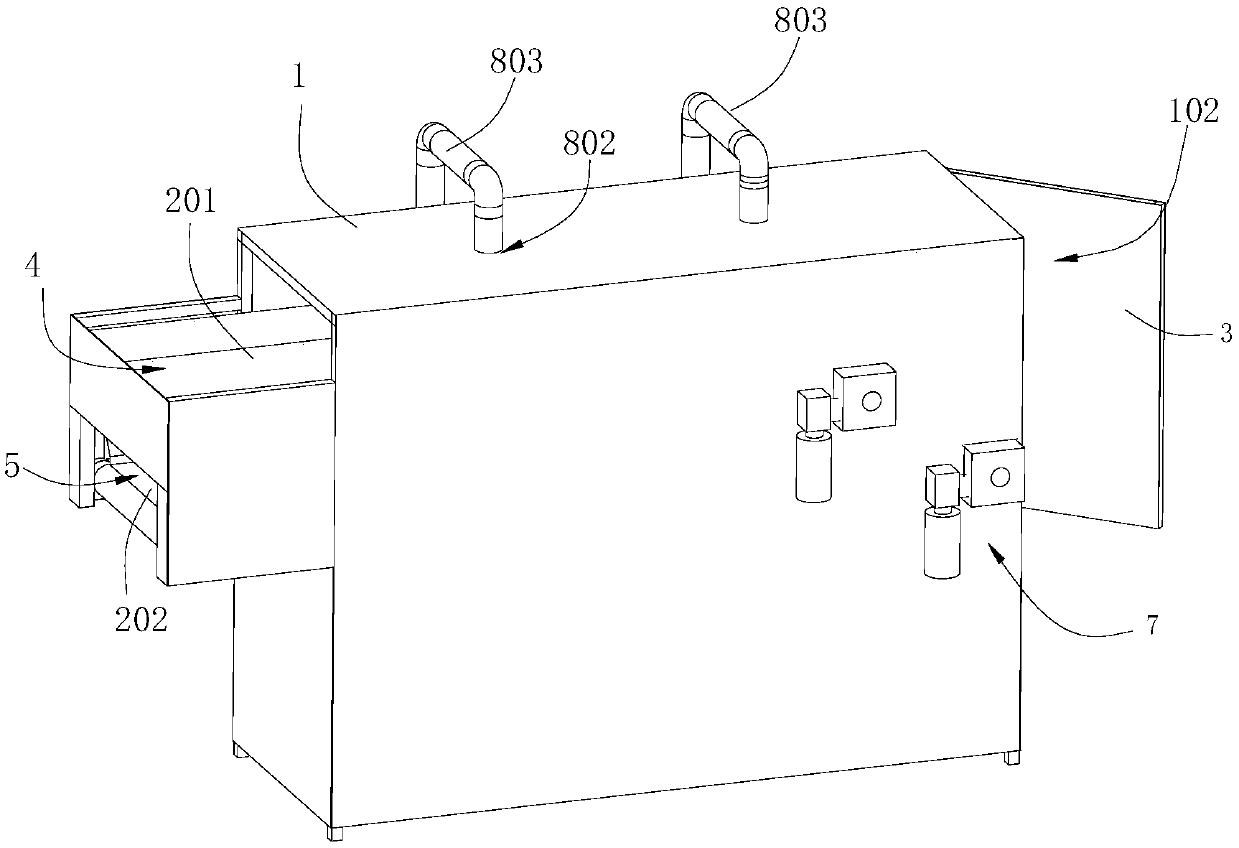

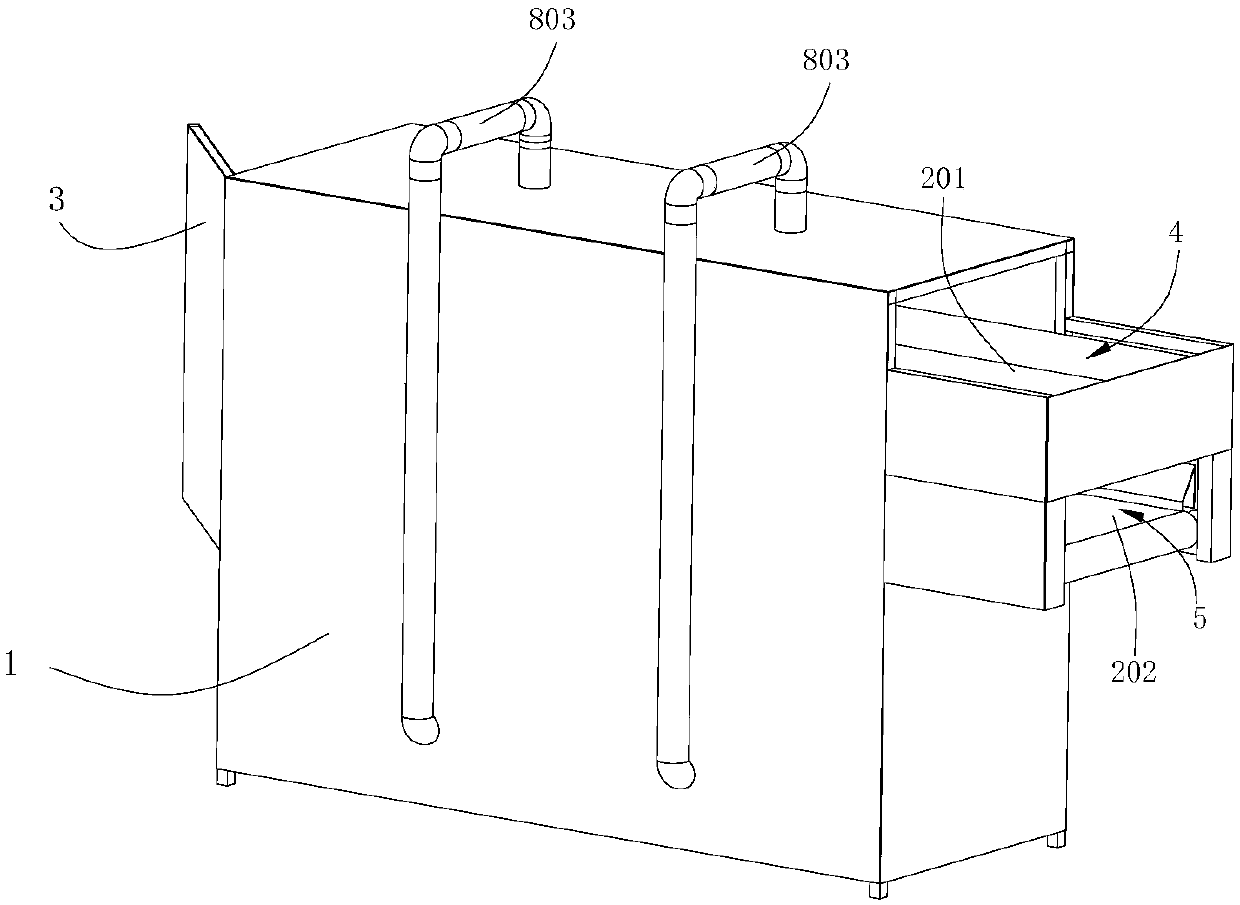

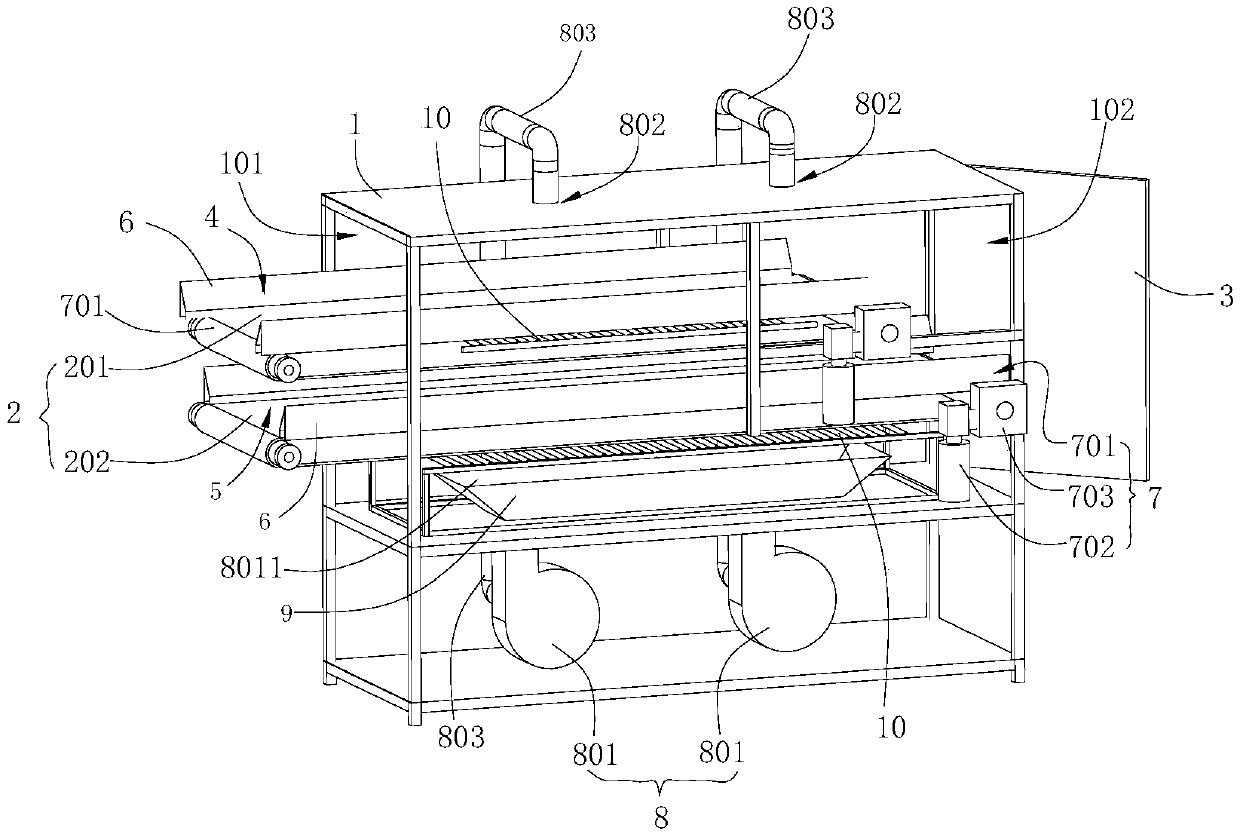

[0040] This embodiment relates to a multi-layer reflux drying device, which includes a box body, a material conveying mechanism and a drying mechanism respectively arranged on the box body, wherein the material conveying mechanism includes a rotating mechanism driven by a driving part and arranged on the box. There are at least two layers of conveyor belts in the body, and the drying mechanism includes an air supply part arranged on the box body to blow air to the materials carried on the conveyor belt, and a heating device arranged on the air supply path of the air supply part. department. The multi-layer reflux drying device is equipped with multi-layer conveyor belts so that the material inlet and discharge port are located at the same end of the box, reducing the ineffective reciprocating movement of employees, thereby improving the work efficiency of employees and utilizing materials. The reciprocating motion on the conveyor belt on different layers increases the contact ...

Embodiment 2

[0054] This embodiment relates to a material sandblasting, washing and drying processing line, such as Figure 7 As shown, it includes a sandblasting machine 11, located below the discharge port of the sandblasting machine 11, to accept the water tank 12 for the discharge of the sandblasting machine 11, and one end extends into the bottom of the water tank 12, so that the materials falling into the water tank 12 The net chain hoist 13 that mentions. When in use, the material falls into the water tank 12 by its own gravity after being blasted by the sandblasting machine 11, so that the material can be cleaned when in contact with the water layer, reducing the trouble of manual cleaning. In order to facilitate the drainage and sand discharge operations of the water tank 12, a sewage valve 1201 is also provided at the bottom of the side wall of the water tank 12 in this embodiment.

[0055] In this embodiment, in order to ensure the stability of material falling, an inclined sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com