Portable electric fruit tree girdling machine and method

A portable, electric technology, applied in the fields of botanical equipment and methods, agricultural machinery and implements, gardening, etc., can solve the problems of inconvenient operation, difficult to uniform force, difficult to grasp the cutting position, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

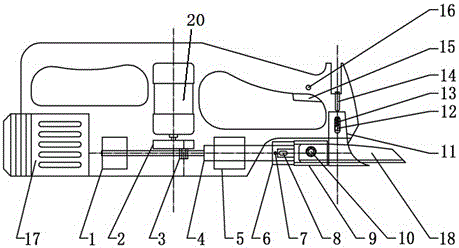

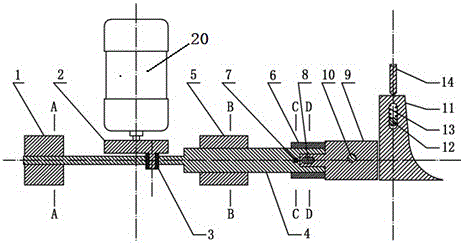

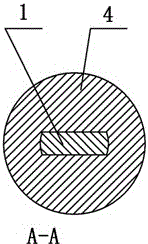

[0030] combined with Figure 1-9 , to further describe the present invention:

[0031] A kind of portable electric fruit tree girdling machine that the present invention mentions comprises fuselage 21, power system, transmission system and cutter head, and described power system adopts battery 17 and DC motor, and power is output to cutter head through transmission system, machine The middle of body 21 is fixed DC motor, and the lower side of fuselage 21 is fixed battery 17, transmission system and cutter head; Limit block 11, and the top of limit block 11 is flexibly connected to the front side of fuselage, the bottom of limit block 11 is arranged on the middle part of two saw blades 18, and the outside of described limit block 11 is arc structure; The rear side of the saw frame 9 is provided with a saw frame locking sleeve 6 and a saw frame locking block 8, and the saw blade 18 is fixed by the saw frame locking sleeve 6, the locking sleeve positioning ball 7 and the saw fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com