Solution feeding system for soilless culture and application

A technology of soilless cultivation and liquid supply, which is applied in the field of soilless cultivation devices, can solve the problems of high cost, and achieve the effects of simple operation, material saving and avoiding clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

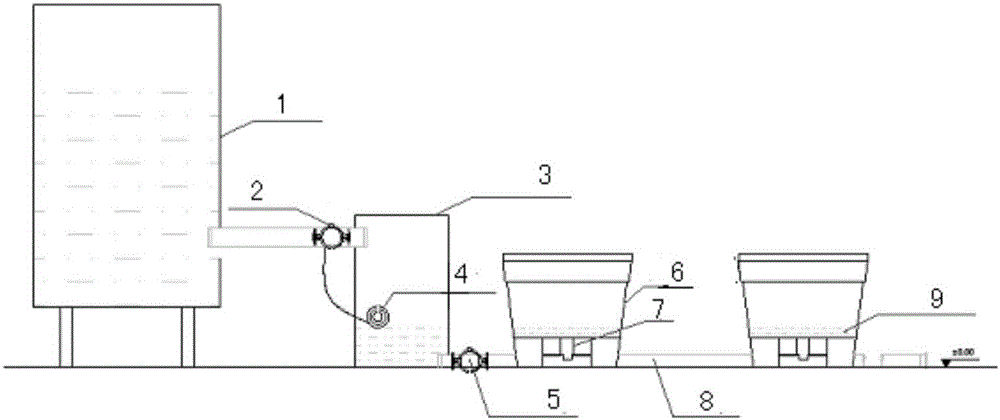

[0038] This embodiment relates to a liquid supply system in soilless cultivation, such as figure 1 As shown, it includes a stock solution barrel 1, a liquid level control barrel 3 and a plurality of substrate cultivation tanks 6 connected in sequence through pipelines;

[0039] The water outlet of the stock liquid barrel 1 is located above the water inlet of the liquid level control barrel 3, so that the stock liquid barrel can supply liquid to the liquid level control barrel by gravity; the liquid level control barrel is provided with an induction liquid The level height and the liquid level sensor 4 for controlling the liquid supply of the raw liquid barrel; the liquid level control barrel 3 communicates with the substrate cultivation tank 6.

Embodiment 2

[0041] This embodiment relates to a liquid supply system for soilless cultivation. Compared with Embodiment 1, the difference is:

[0042] A valve 2 is provided between the stock solution barrel 1 and the liquid level control barrel 3.

[0043] A valve 5 is provided between the liquid level control barrel 3 and the substrate cultivation tank 6 .

[0044] The horizontal position of the stock solution barrel 1 is above the liquid level control barrel 3 .

[0045] The liquid level sensor 4 is a float valve.

Embodiment 3

[0047] This embodiment relates to a liquid supply system for soilless cultivation, which includes a stock solution tank, a liquid level control tank and a plurality of substrate cultivation tanks connected in sequence through pipelines;

[0048] The horizontal position of the stock liquid barrel is located above the water inlet of the liquid level control barrel, so as to realize that the stock liquid barrel supplies liquid to the liquid level control barrel by gravity; a float valve is arranged in the liquid level control barrel; The liquid level control barrel is connected with the substrate cultivation tank;

[0049] The substrate cultivation tank is sequentially provided with a supporting porous partition, a filtering porous material, a culture substrate and a cover plate with planting holes from bottom to top, and the cover completely covers the opening of the cultivation tank , a liquid supply port protruding downward is provided on the lower surface of the matrix cultivat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com