Normal-temperature yoghourt and preparation method thereof

A normal temperature, yogurt technology, applied in the direction of milk preparations, dairy products, applications, etc., can solve the problems of destroying the structure of yogurt, low product viscosity, layering, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

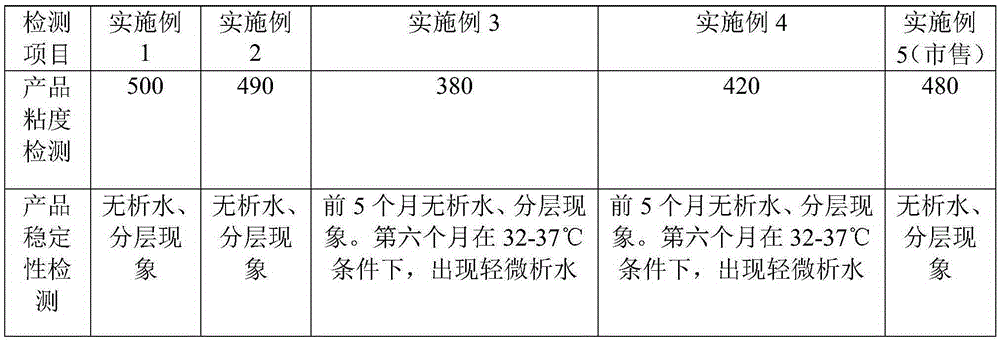

Examples

Embodiment 1

[0020] 1. Raw materials

[0021] The raw materials include: 860 to 940 parts by weight of milk, 12 to 20 parts by weight of a stabilizer, and the stabilizer is composed of 1.5 to 2.5 parts by weight of agar, 1.5 to 2.5 parts by weight of pectin and 5 to 15 parts by weight of modified starch.

[0022] 2. Preparation method

[0023] 1. Acceptance, purification and sterilization of raw milk:

[0024] 1.1 Acceptance of raw milk: Acceptance of raw milk according to the national standard GB 19301 raw milk standard.

[0025] 1.2 Purification of raw milk: Raw milk is stored after coarse filtration, fine filtration, milk cleaning and cooling.

[0026] 1.3 Pasteurization of raw milk: Pasteurization temperature is 85°C, time is 15 seconds, cooled to below 4°C for storage. Pasteurized milk reduces the number of microorganisms in the milk.

[0027] 2. Ingredients: Warm up the milk, mix the stabilizer and white sugar in advance. Add the stabilizer, white sugar, cream, and whey protein p...

Embodiment 2

[0037] 1. Raw materials

[0038] The raw materials include: 860 to 940 parts by weight of milk, 12 to 20 parts by weight of a stabilizer, the stabilizer is composed of 1.5 to 2.5 parts by weight of agar, 1.5 to 2.5 parts by weight of pectin and 5 to 15 parts by weight of modified starch, 3 parts by weight of cream 8 parts by weight, 65 to 90 parts by weight of white granulated sugar and 1 to 5 parts by weight of whey protein powder.

[0039] 2. Preparation method

[0040] 1. Acceptance, purification and sterilization of raw milk

[0041] 1.1 Acceptance of raw milk: Acceptance of raw milk according to the national standard GB 19301 raw milk standard.

[0042] 1.2 Purification of raw milk: Raw milk is stored after coarse filtration, fine filtration, milk cleaning and cooling.

[0043] 1.3 Pasteurization of raw milk: Pasteurization temperature is 85°C, time is 15 seconds, cooled to below 4°C for storage. Pasteurized milk reduces the number of microorganisms in the milk.

[0...

Embodiment 3

[0062] 1. Raw materials

[0063] The raw materials include: 700 to 950 parts by weight of milk, 10 to 20 parts by weight of a stabilizer, and the stabilizer is composed of 0.5 to 3 parts by weight of agar, 0.5 to 3 parts by weight of pectin and 5 to 20 parts by weight of modified starch.

[0064] 2. Preparation method

[0065] 1. Raw milk inspection, purification and sterilization

[0066] 1.1 Acceptance of raw milk: Acceptance of raw milk according to the national standard GB 19301 raw milk standard.

[0067] 1.2 Purification of raw milk: Raw milk is stored after coarse filtration, fine filtration, milk cleaning and cooling.

[0068] 1.3 Raw milk is sterilized at 135-137°C for 4-6 seconds, then cooled to below 7°C for storage.

[0069] 2. Ingredients: heat up the milk, mix the stabilizer and white sugar in advance; keep the material added with the stabilizer at 10 to 75 degrees for 5 to 15 minutes, so that the stabilizer and other materials are fully dissolved and cooled t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com