Method for producing frothy coffee drink via biological methods

A technology of coffee beverage and biological method, which is applied in the direction of coffee extraction, etc., can solve the problem that the concentration of yeast fermented coffee solids and product quality requirements have not been accurately and detailedly elaborated, so as to achieve beneficial multiplication, economical use, The effect of stabilizing the fermentation environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

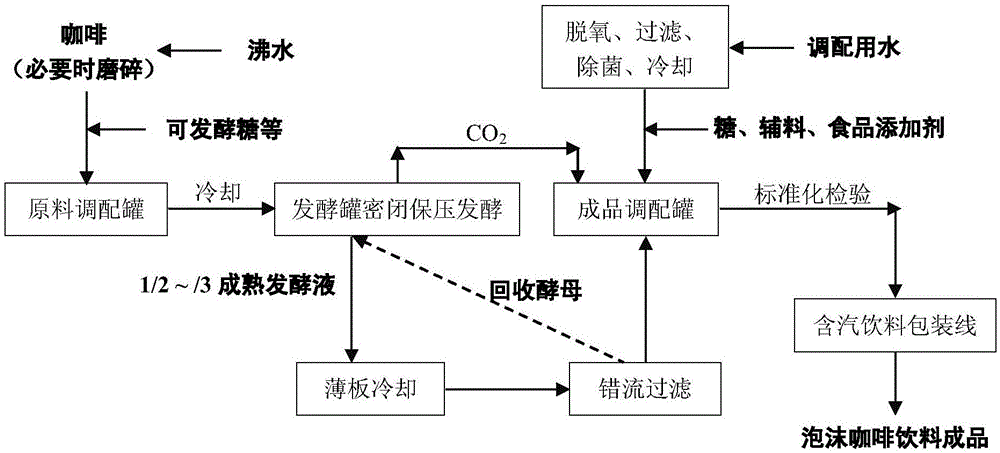

Method used

Image

Examples

Embodiment 1

[0031] It uses coffee powder, white sugar, brewer's yeast and xylitol as raw materials.

[0032] 1. Preparation of coffee sugar solution

[0033] Extract coffee powder with boiling water to obtain a coffee solution, add white granulated sugar to dissolve and adjust the coffee solids concentration in the coffee sugar solution to not less than 1.0% (mass ratio, m / m), and the fermentable sugar content is 3.0% (mass ratio Ratio, m / m), the obtained coffee sugar solution was cooled to 15°C. Saccharomyces cerevisiae was inoculated in the cooled coffee sugar solution, and the number of living cells in the solution after inoculation was 1.9×10 7 cell / mL.

[0034] 2. Preparation of water for deployment

[0035] N 2 or CO 2 Introduced from the bottom of the preparation tank to drive off the air in the tank to form a stable layer of inert gas. The preparation water is deoxidized, sterilized, cooled to 1°C, and transferred from the bottom of the preparation tank into the tank to diss...

Embodiment 2

[0042] It uses instant coffee, brown sugar, white granulated sugar and Saccharomyces cerevisiae as raw materials.

[0043] 1. Preparation of coffee sugar solution

[0044] Extract instant coffee with boiling water to obtain a coffee solution, add brown sugar to dissolve and adjust the concentration of coffee solids in the coffee sugar solution to not less than 2.5% (mass ratio, m / m), and the fermentable sugar content is 2.0% (mass ratio , m / v), the obtained coffee sugar solution was cooled to 12°C. Inoculate Saccharomyces cerevisiae in the cooled coffee sugar solution, the number of living cells in the solution after inoculation is not less than 1.6×10 7 cell / mL.

[0045] 2. Preparation of water for deployment

[0046] N 2 or CO 2 Introduced from the bottom of the preparation tank to drive off the air in the tank to form a stable layer of inert gas. The preparation water is deoxidized, sterilized, cooled to 3°C, and transferred from the bottom of the preparation tank int...

Embodiment 3

[0053] Made with decaffeinated coffee powder, sucrose, and active dry Saccharomyces cerevisiae.

[0054] 1. Preparation of coffee sugar solution

[0055] Extract the decaffeinated coffee powder with boiling water to obtain a coffee solution, add sucrose to dissolve and adjust the concentration of coffee solids in the coffee sugar solution to not less than 2.5% (mass ratio, m / m), and the fermentable sugar content is 3.0% (mass ratio, m / m), the obtained coffee sugar solution was cooled to 22°C. Saccharomyces cerevisiae was inoculated in the cooled coffee sugar solution, and the number of viable cells in the solution after inoculation was 1.2×10 7 cell / mL.

[0056] 2. Preparation of water for deployment

[0057] N 2 or CO 2 Introduced from the bottom of the preparation tank to drive off the air in the tank to form a stable layer of inert gas. The preparation water is deoxidized, sterilized, cooled to 2°C, and transferred from the bottom of the preparation tank into the tank...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com