Sulfur-free sugar-free pearl plum preserved fruit processing method

A processing method and pearl technology, which are applied in the confectionery industry, confectionery, food science and other directions, can solve the problems of insufficient tissue morphology, low production effect, long time consumption, etc., and achieve increased color and luster, brightness, fullness and stability. Sex, health effects of eating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

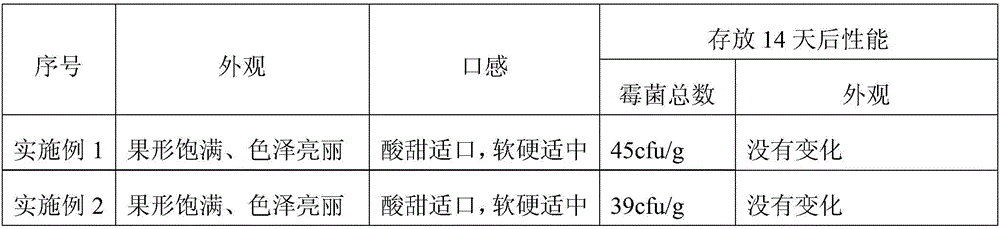

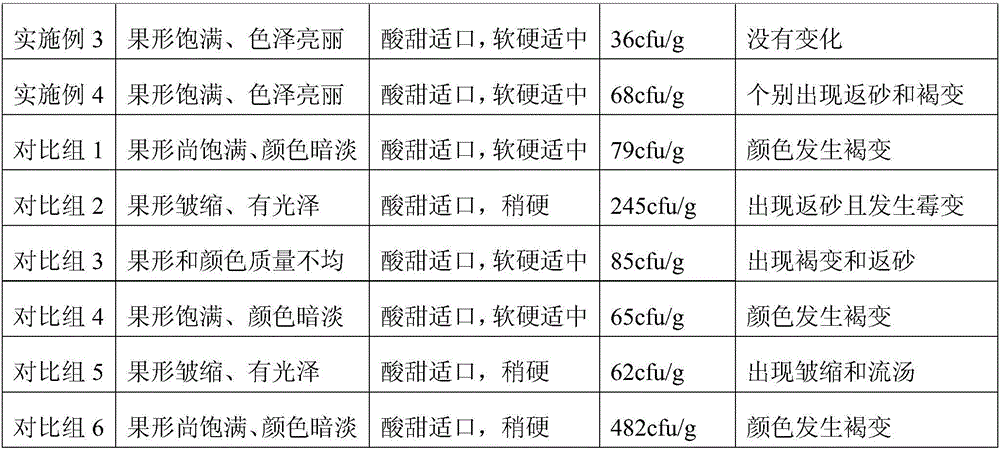

Examples

Embodiment 1

[0033] A method for processing sulfur-free and sugar-free pearl plum fruit, comprising the following steps:

[0034] (1) Hardening color protection: prepare hardening color protection agent, take 0.2% CaCl by weight percentage 2, 0.3% citric acid, 0.1% salt, 0.1% Vc, 0.2% D-sodium erythorbate, the balance is water, and mix all the components; take the pearl plum fruit, wash and remove the core, put the pearl plum pulp Put it into the hardening color-protecting agent, soak it for 5 hours at normal temperature, then take out the pearl plum pulp, rinse it and drain the water; the amount of hardening color-protecting agent is preferably to submerge the pearl plum pulp;

[0035] (2) Candied cooking: prepare candied cooking liquid, which is 25% maltitol, 0.02% acesulfame potassium, 0.3% CMC-Na, 4% edible cassava whole powder and 0.15% guar gum by mass fraction, and the balance is water Take the raw materials, mix all the raw materials to obtain the candied liquid; according to the ...

Embodiment 2

[0042] A method for processing sulfur-free and sugar-free pearl plum fruit, comprising the following steps:

[0043] (1) Hardening color protection: prepare hardening color protection agent, take 0.5% CaCl by weight percentage 2 , 0.05% citric acid, 0.2% salt, 0.3% Vc, 0.1% D-sodium erythorbate, the balance is water, and all the components are mixed; take the pearl plum fruit, wash and remove the core, put the pearl plum pulp Put it into the hardening color-protecting agent, soak it at room temperature for 5.5 hours, then take out the pearl plum pulp, rinse it and drain the water; the dosage of the hardening color-protecting agent is preferably to submerge the pearl plum pulp;

[0044] (2) Candied cooking: prepare candied cooking liquid, which is 35% maltitol, 0.01% acesulfame potassium, 0.5% CMC-Na, 8% edible cassava whole powder and 0.05% guar gum by mass fraction, and the balance is water Take the raw materials, mix all the raw materials to get the candied liquid; accordin...

Embodiment 3

[0051] A method for processing sulfur-free and sugar-free pearl plum fruit, comprising the following steps:

[0052] (1) Hardening color protection: prepare hardening color protection agent, take 0.4% CaCl by weight percentage 2 , 0.15% citric acid, 0.15% salt, 0.2% Vc, 0.15% D-sodium erythorbate, the balance is water, and mix all the components; take the pearl plum fruit, wash and remove the core, put the pearl plum pulp Put it into the hardening color-protecting agent, soak it at room temperature for 5.5 hours, then take out the pearl plum pulp, rinse it and drain the water; the dosage of the hardening color-protecting agent is preferably to submerge the pearl plum pulp;

[0053] (2) Candied cooking: prepare candied cooking liquid, which is 30% maltitol, 0.015% acesulfame potassium, 0.4% CMC-Na, 5% edible cassava whole powder and 0.1% guar gum by mass fraction, and the balance is water Take the raw materials, mix all the raw materials to obtain the candied liquid; according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com